About Neo Roman™

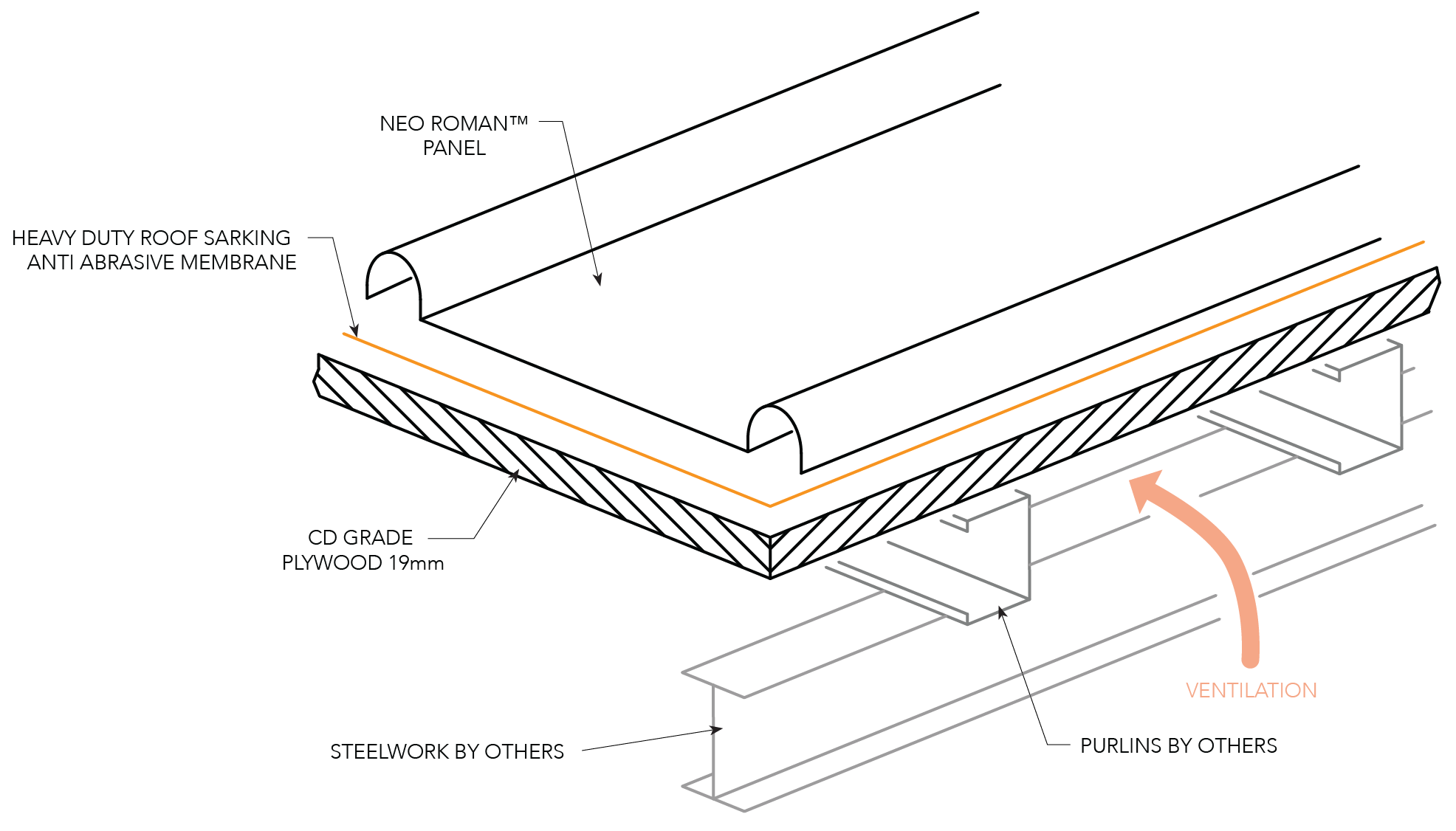

Neo Roman™ is manufactured exclusively by Fielders® and is available in a wide range of material including ZINCALUME®, COLORBOND® , COLORBOND® Ultra, COLORBOND® Metallic, copper and stainless steel. Neo Roman™ is installed on a ply substrate and in most cases can be installed to a minimum pitch of 5°.

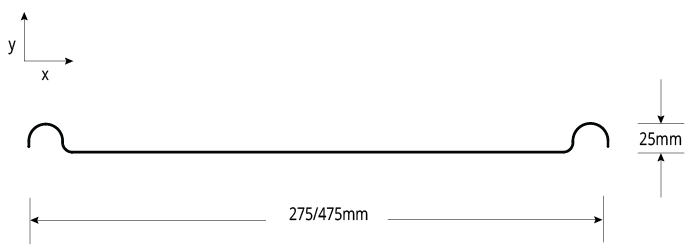

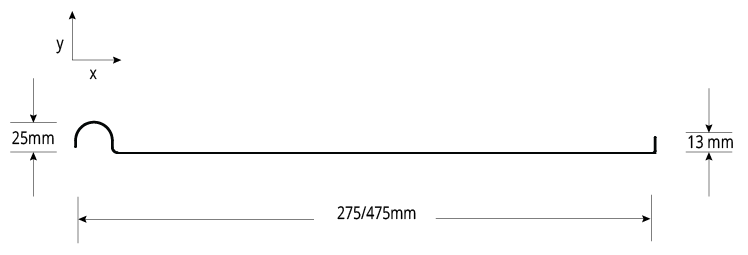

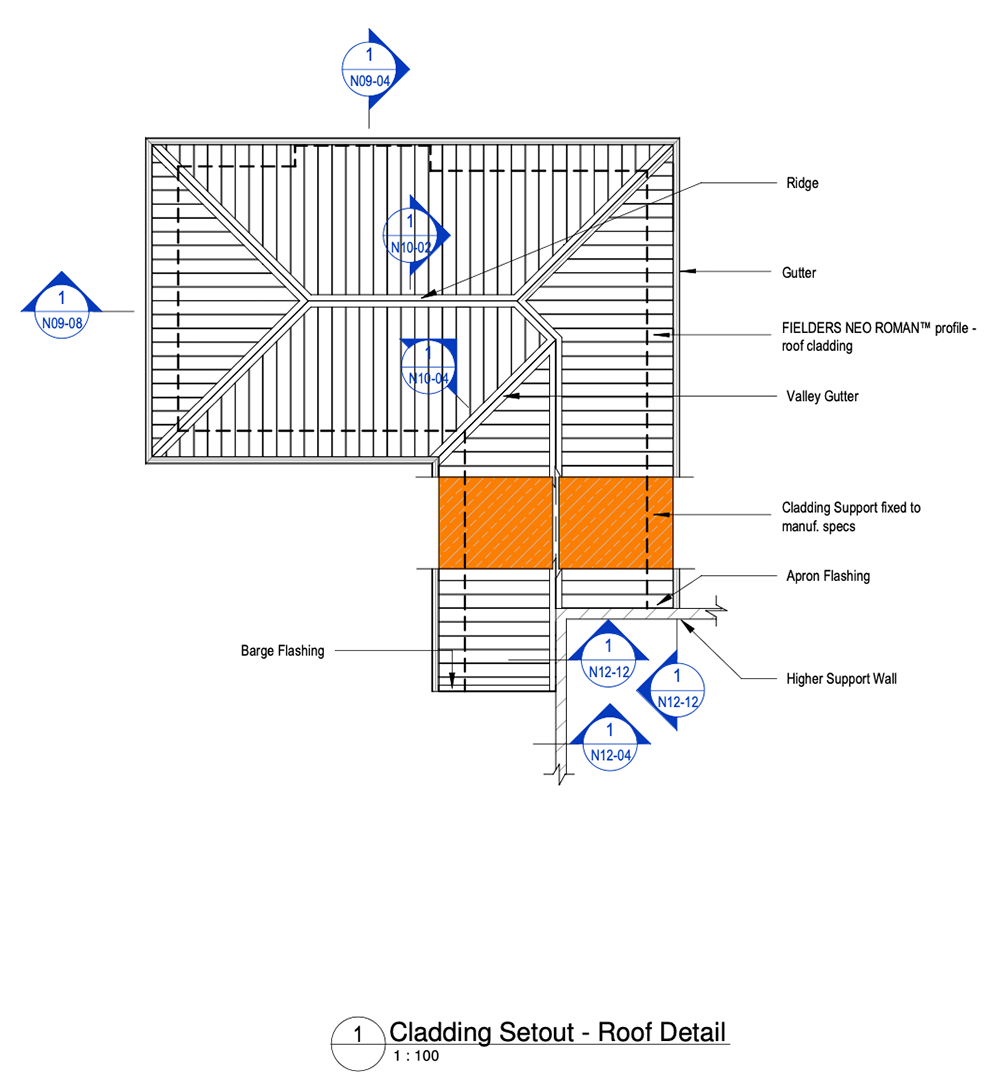

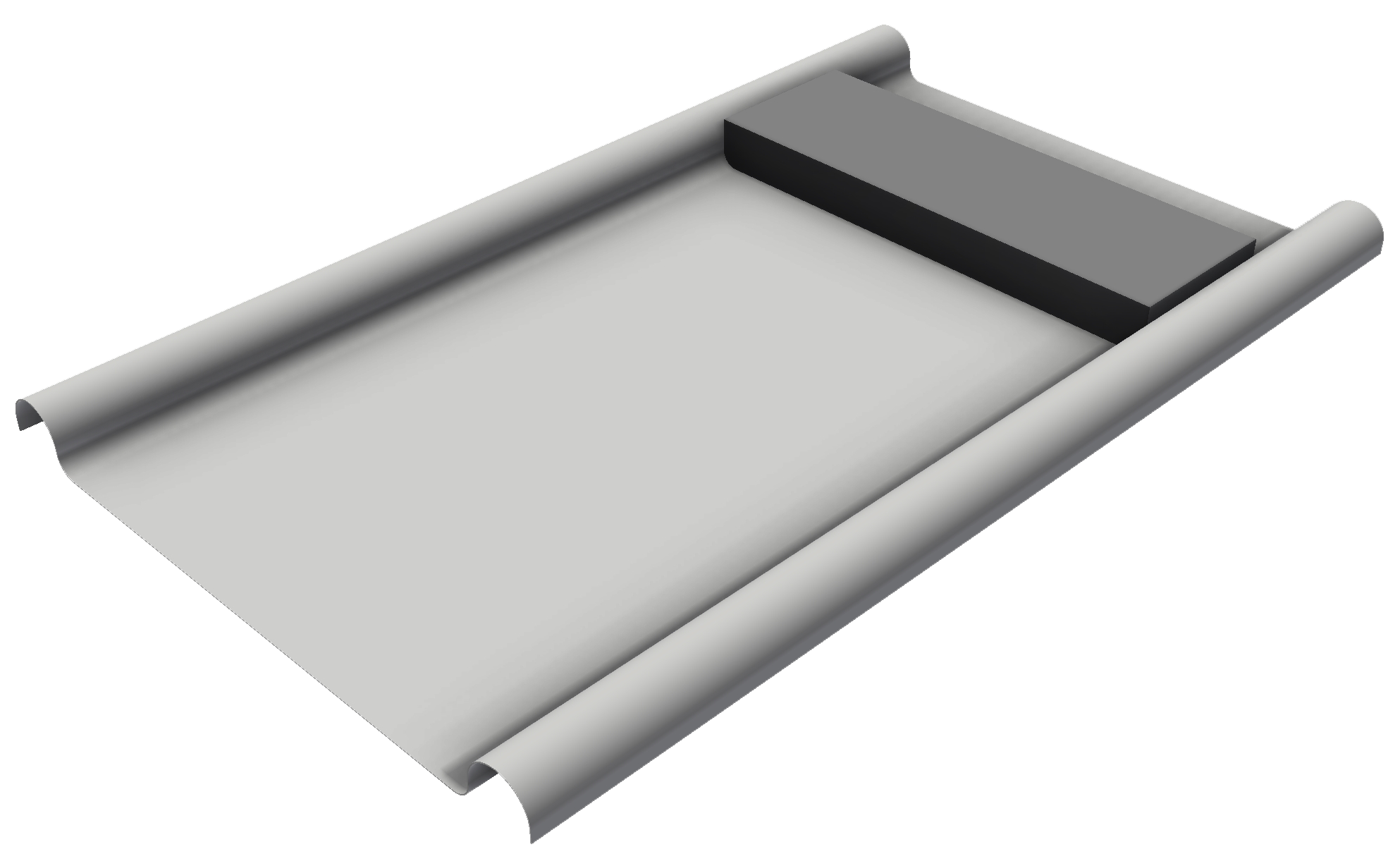

Fielders® Neo Roman™ utilises the ancient Roman roofing profile to create aesthetically pleasing and functional roofing solutions. Neo Roman™ is available in standard 275mm and 475mm cover widths. The rib height of the Neo Roman™ profile is 25mm.

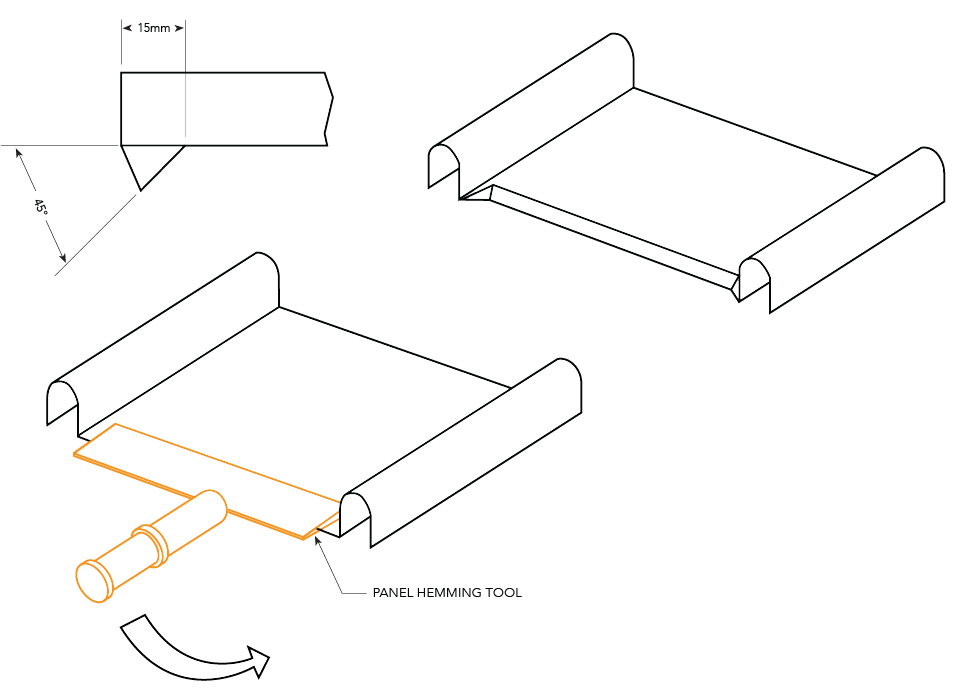

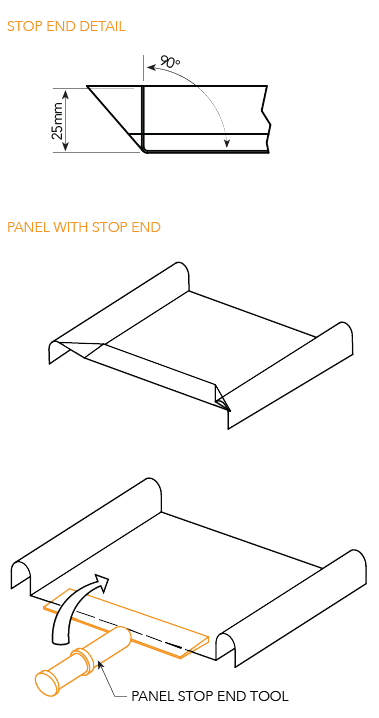

Neo Roman™ offers many creative possibilities with the profile being able to be used as either a roof or wall cladding. It can also be made with both ribs and pan (Figure NR ID NC 001) in the one piece or alternatively with only one rib (Figure NR ID NC 003). Both the single and double rib profiles come in a maximum sheet length of 4000mm with the double rib profile fixed through the crest of the rib.

Material Specifications

| Property | 275mm Pan Width | 475mm Pan Width | Notes | |||

| Base Metal Thickness (mm) | 0.55 | 0.75 | 0.55 | 0.75 | BMT | |

| Total Coated Thickness (mm) | 0.60* | 0.80* | 0.60* | 0.80* | TCT | |

| Mass / Unit Length | ZINCALUME® | 1.83 | 2.41 | 2.75 | 3.61 | kg/m |

| COLORBOND® | 1.86* | 2.44* | 2.80* | 3.66* | ||

| Mass / Unit Area | ZINCALUME® | 6.65 | 8.76 | 5.79 | 7.61 | kg/m2 |

| COLORBOND® | 6.76* | 8.87* | 5.90* | 7.71* | ||

| Coverage | 275 | 275 | 475 | 475 | mm | |

| Minimum Yield Strength | G300 | MPa | ||||

| Coating Class | AM100 - COLORBOND® Steel AM125 - ZINCALUME® AM150 - COLORBOND® Ultra Steel | Minimum Coating g/m2 of Zinc - Aluminium |

||||

| Tolerance | Sheet length ±7mm Cover width ± 4mm | |||||

| Thermal Expansion | 2.9mm average per 5.0 metre @ 50˚C change | |||||

Notes:

- The COLORBOND®; and ZINCALUME® material is in accordance to AS 1397, AS 1365 and AS 2728. The installation of the cladding should be in accordance to AS 1562.1 and HB39.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

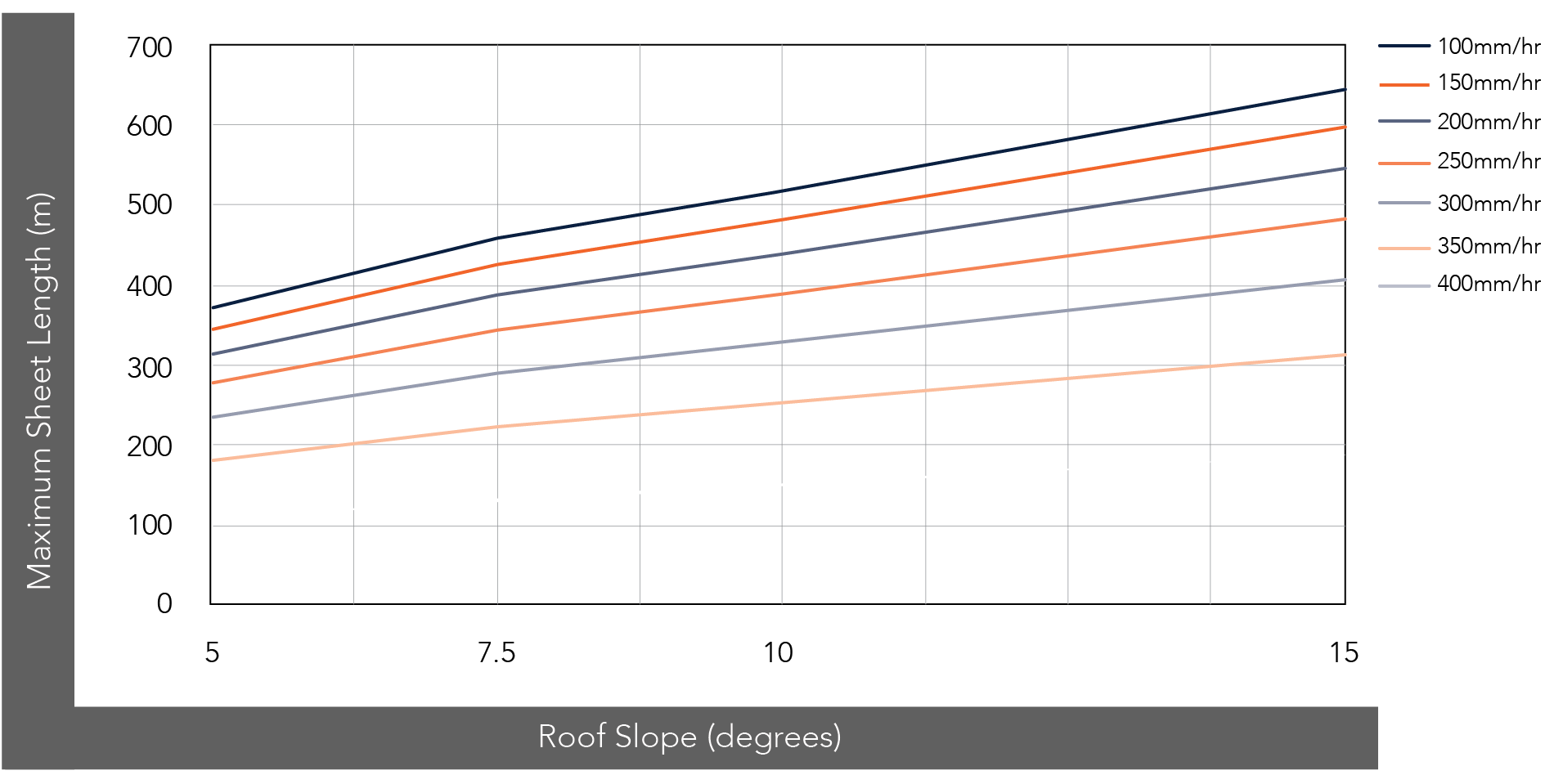

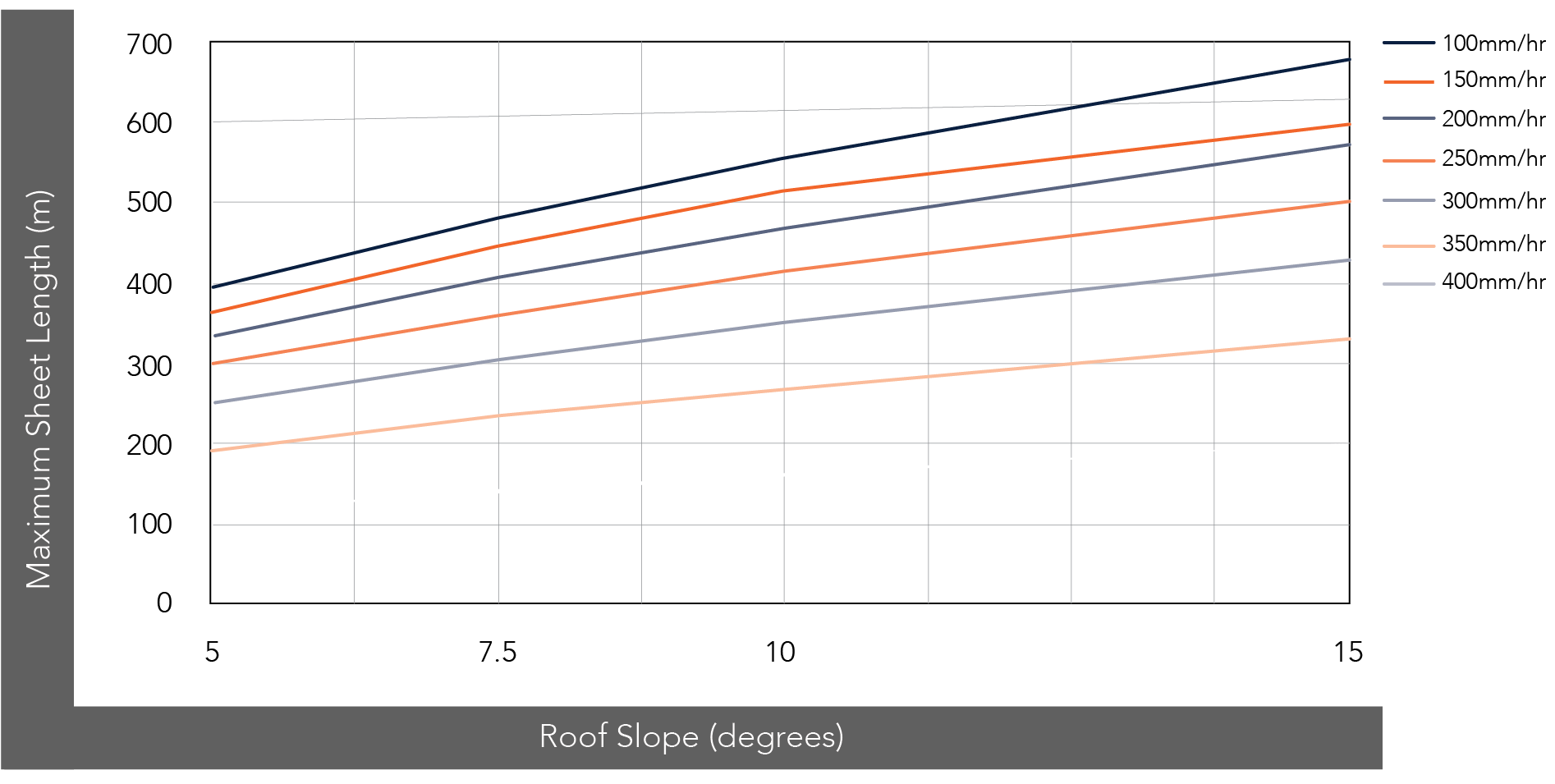

Rainfall Capacity

For further information, please refer to sections “Rainfall Intensity” and “Water Carrying Capacity and Rainwater Run-Off”.

Figure NR (275) RC NC 001

Maximum Roof Length (m) 275 Single Rib Non-Cyclonic

| Roof Slope (degrees) | Rainfall Capacity (mm/hr) | ||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | |

| 5 | 108 | 72 | 54 | 43 | 36 | 31 | 27 |

| 7.5 | 133 | 89 | 67 | 53 | 44 | 38 | 33 |

| 10 | 151 | 101 | 76 | 60 | 50 | 43 | 38 |

| 15 | 187 | 125 | 94 | 75 | 62 | 53 | 47 |

Note:

- Minimum recommended slope is 5°. Sheet lengths greater than 15m are not recommended due to thermal expansion and contraction.

Figure NR (475) RC NC 002

Maximum Roof Length (m) 475 Single Rib 475 Non-Cyclonic

| Roof Slope (degrees) | Rainfall Capacity (mm/hr) | ||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | |

| 5 | 115 | 77 | 58 | 46 | 38 | 33 | 29 |

| 7.5 | 140 | 94 | 70 | 56 | 47 | 40 | 35 |

| 10 | 162 | 108 | 81 | 65 | 54 | 46 | 41 |

| 15 | 198 | 132 | 99 | 79 | 66 | 57 | 50 |

Note:

- Minimum recommended slope is 5°. Sheet lengths greater than 24m are not recommended due to thermal expansion and contraction.

Preserving Our Heritage

The use of BlueScope Z600 Heritage Galvanised coil (the old double dipped two ounce galv) provides the opportunity for architects to match, replace or recreate the roofs of some of Australia’s most magnificent old buildings.

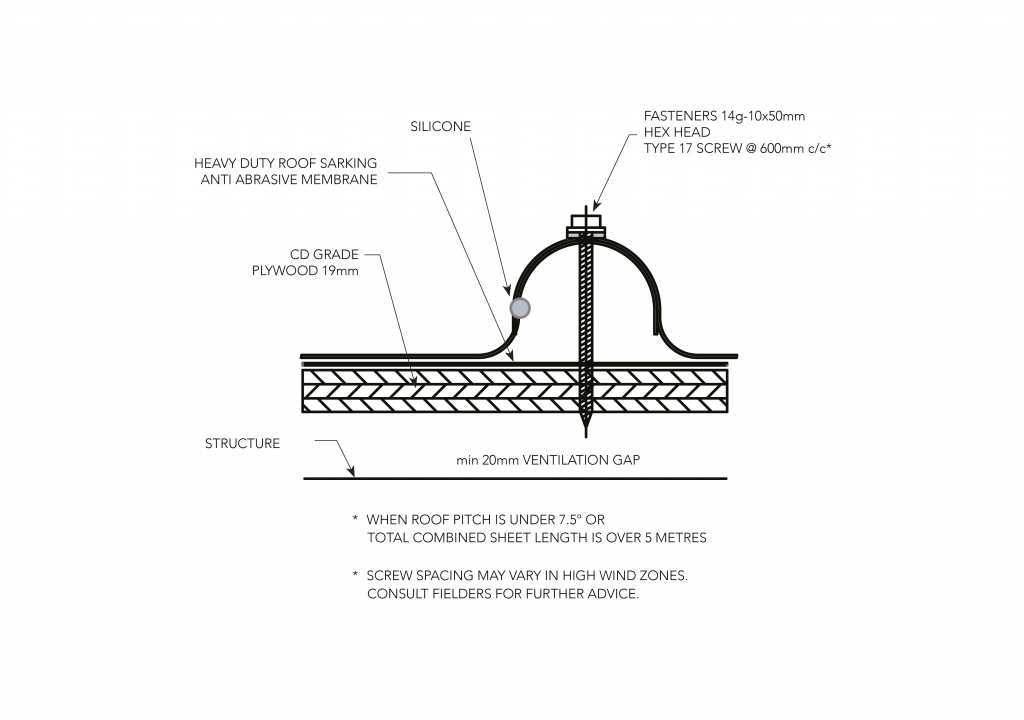

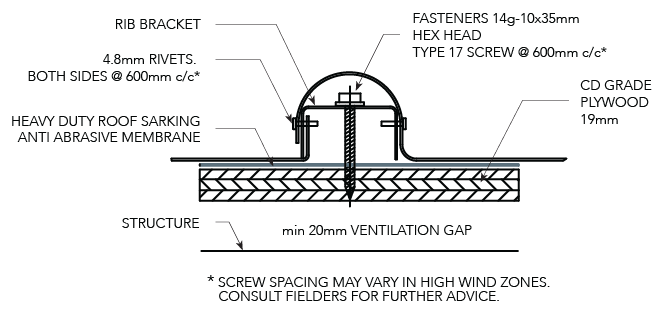

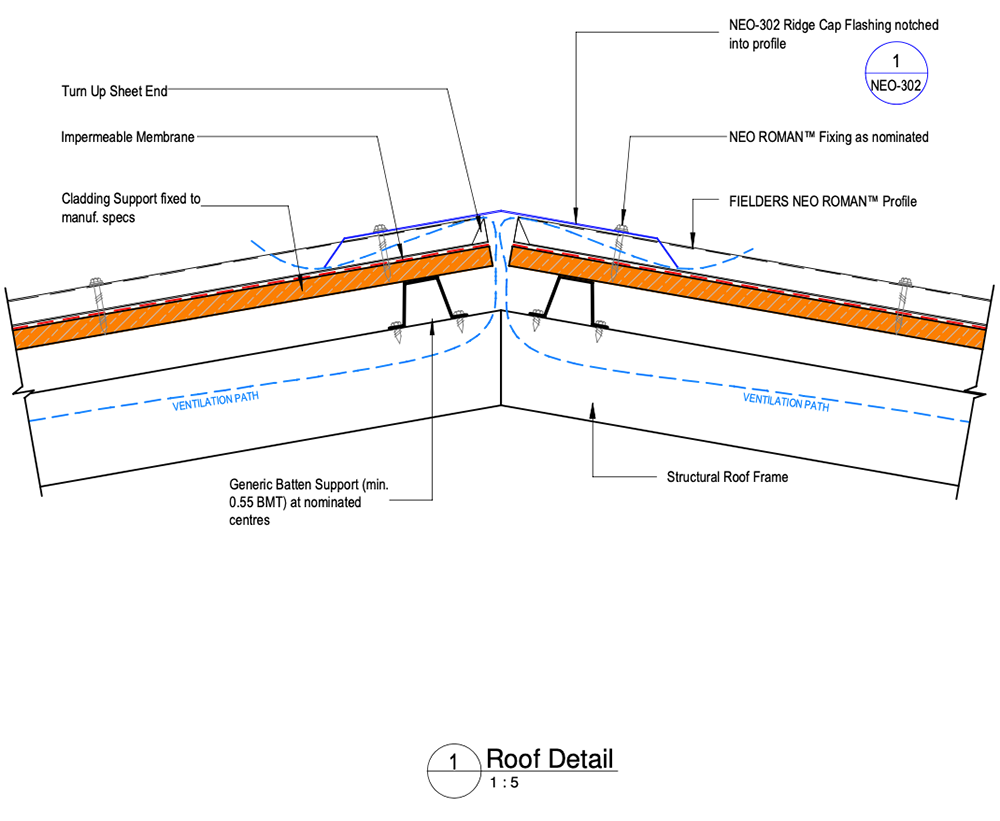

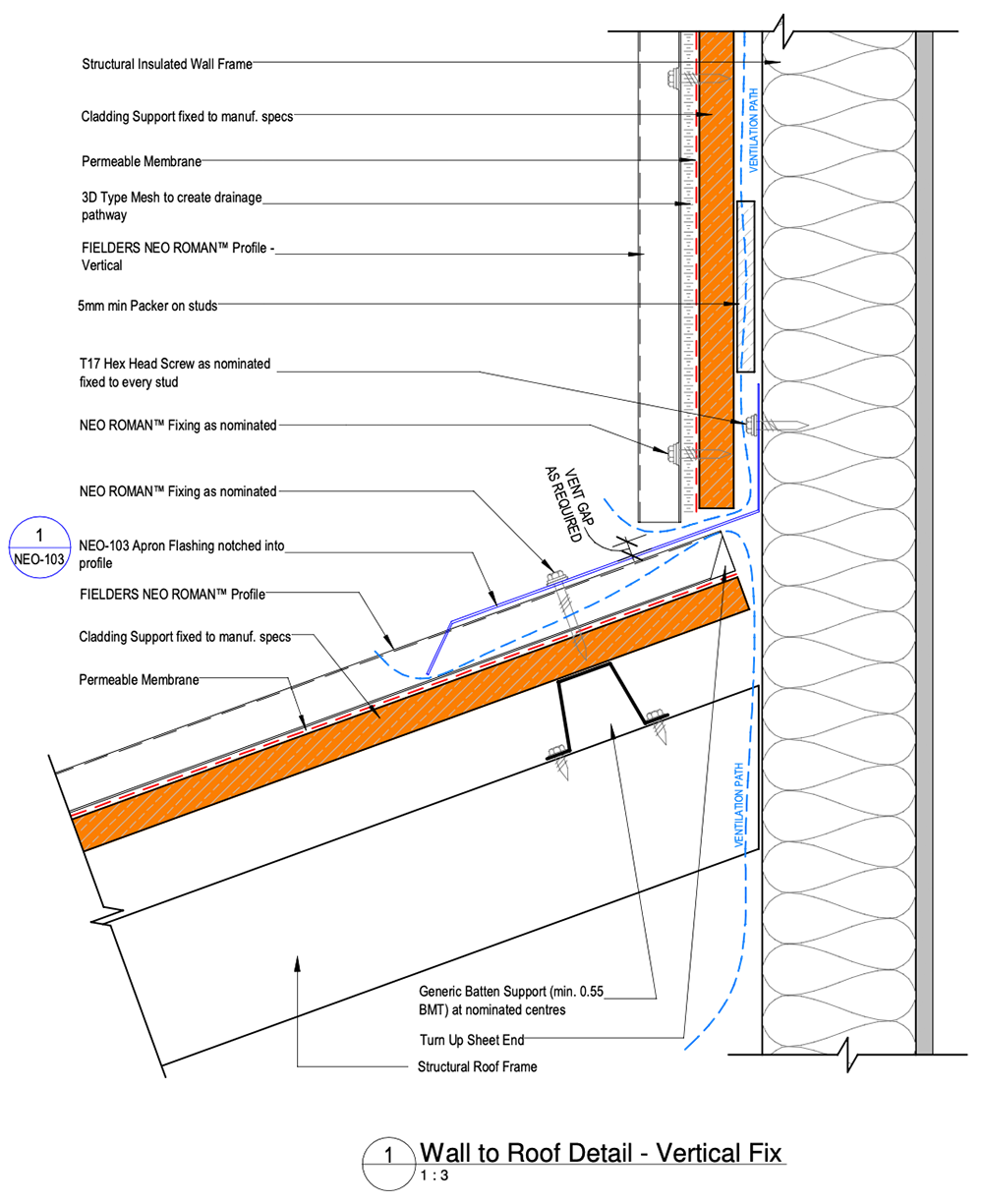

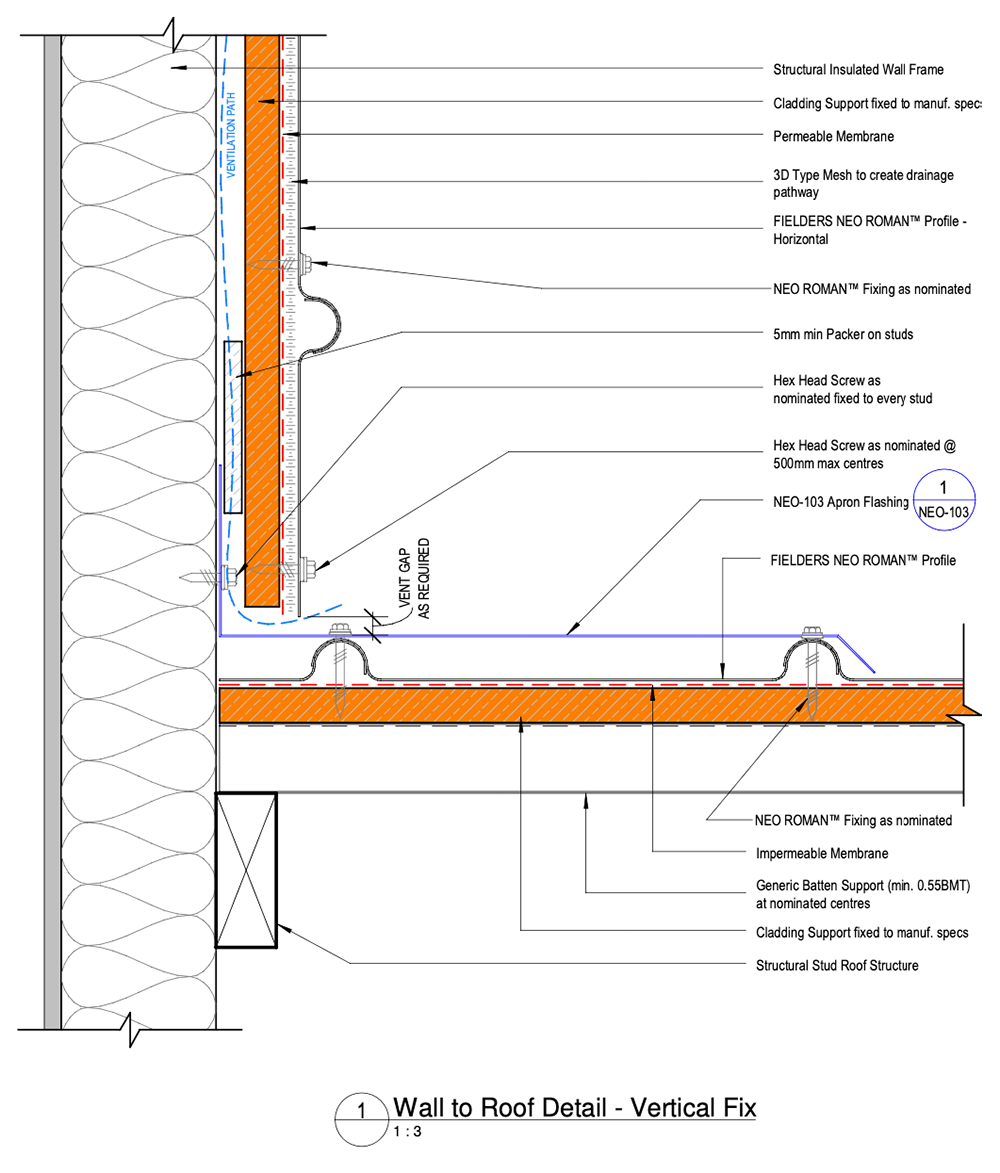

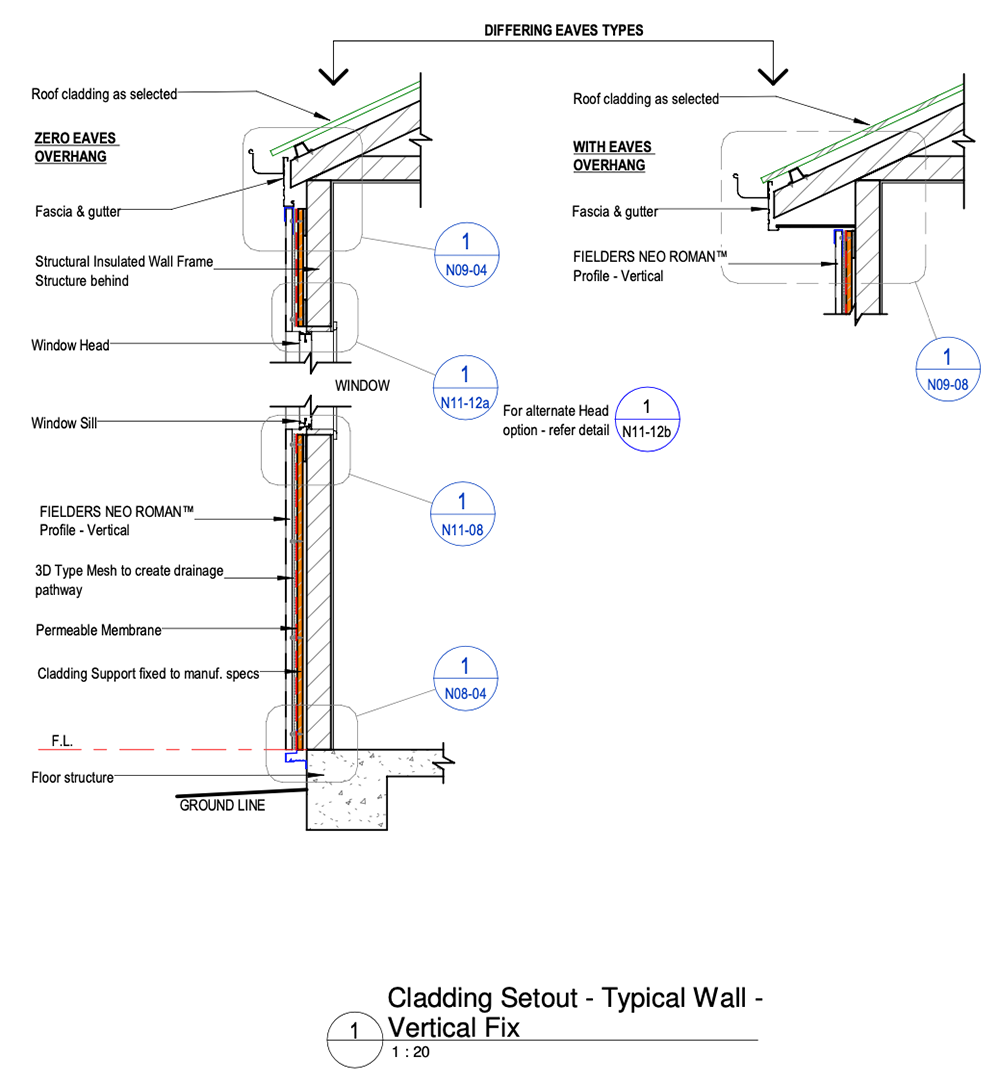

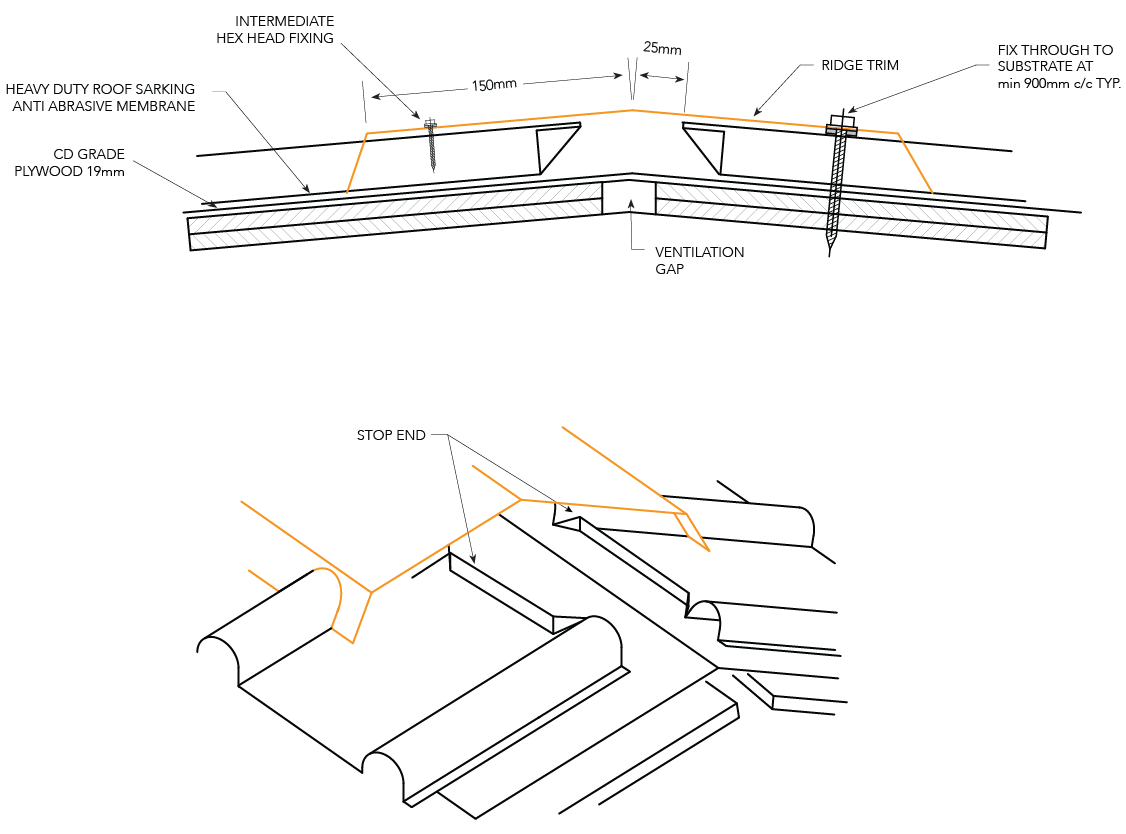

Roof Cladding

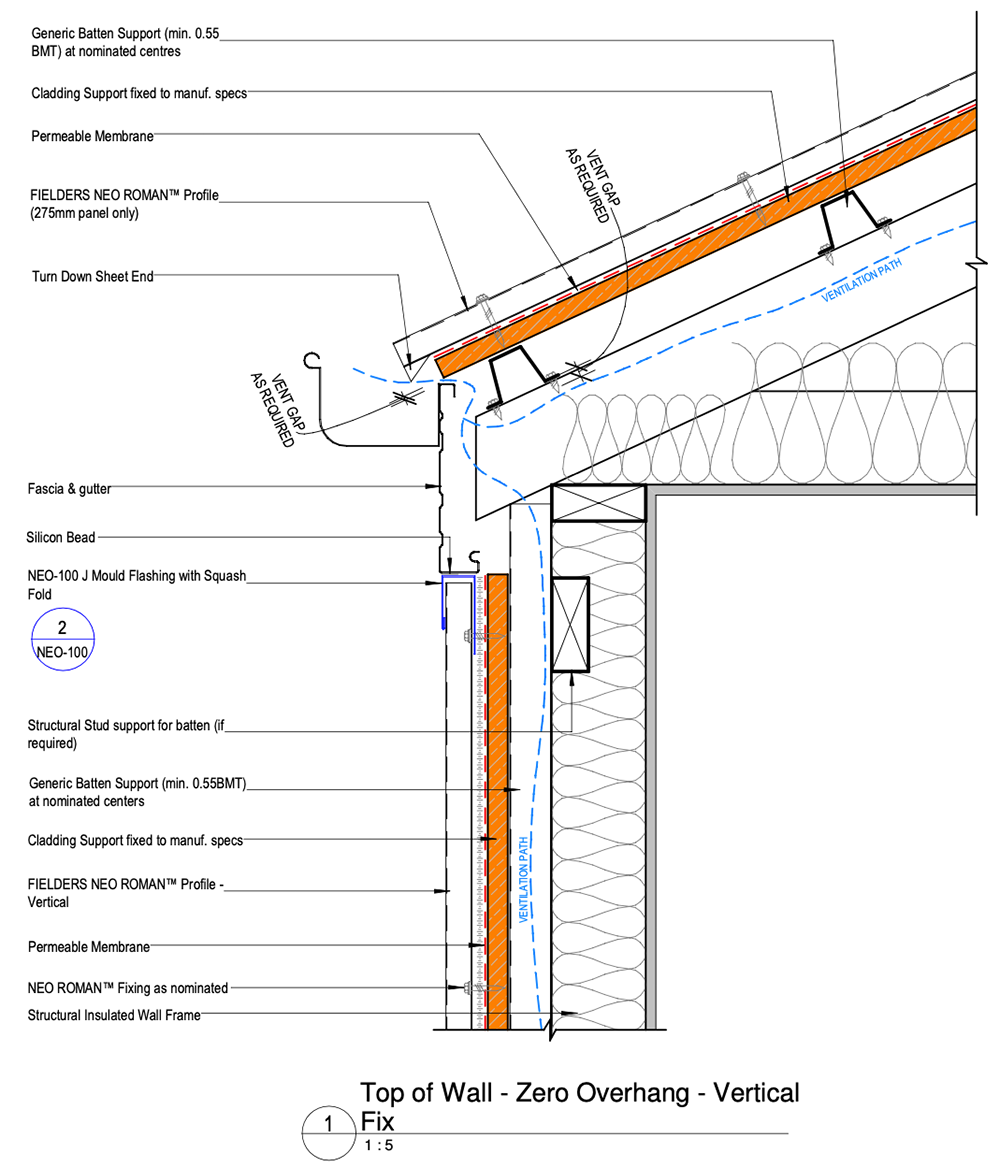

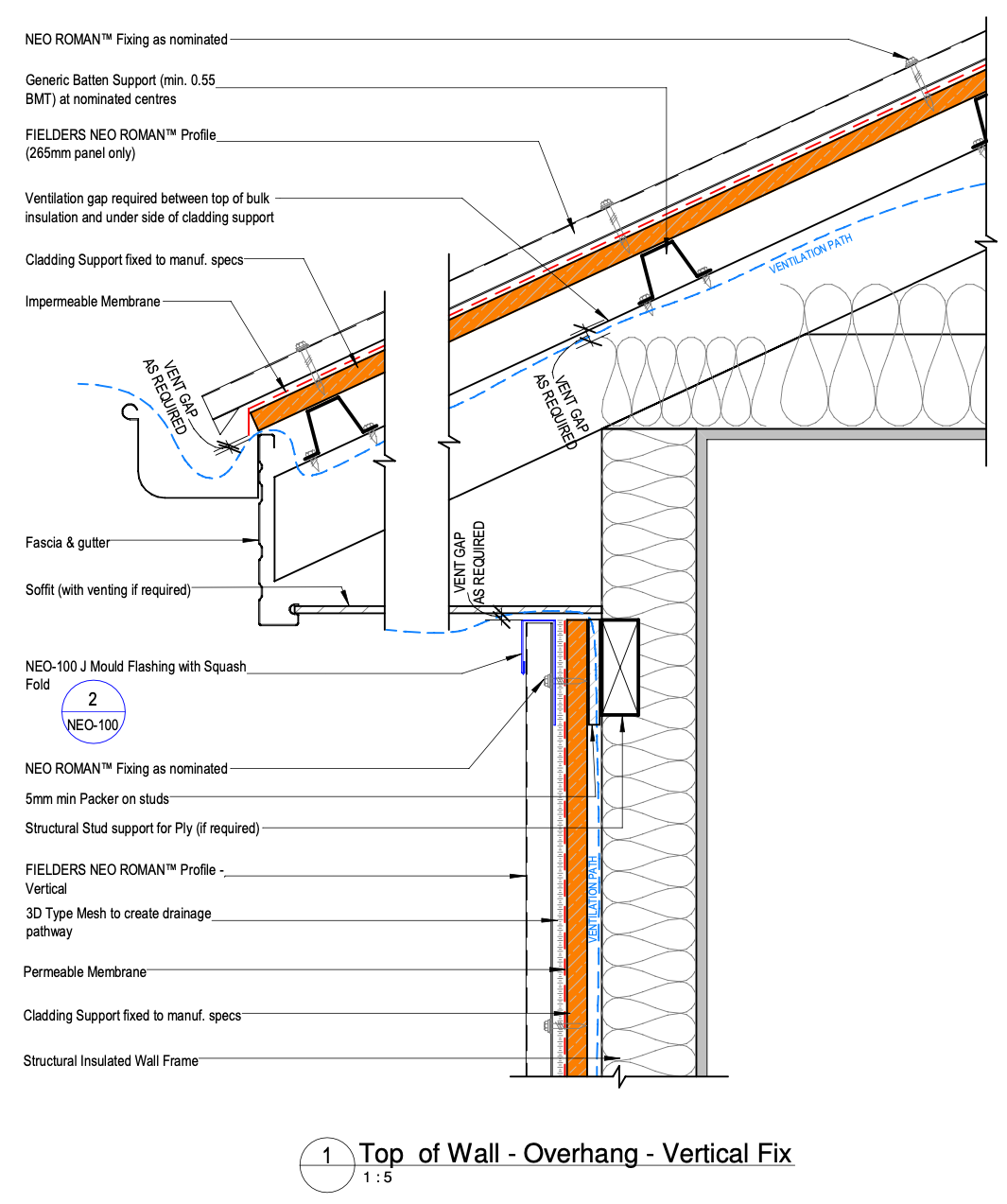

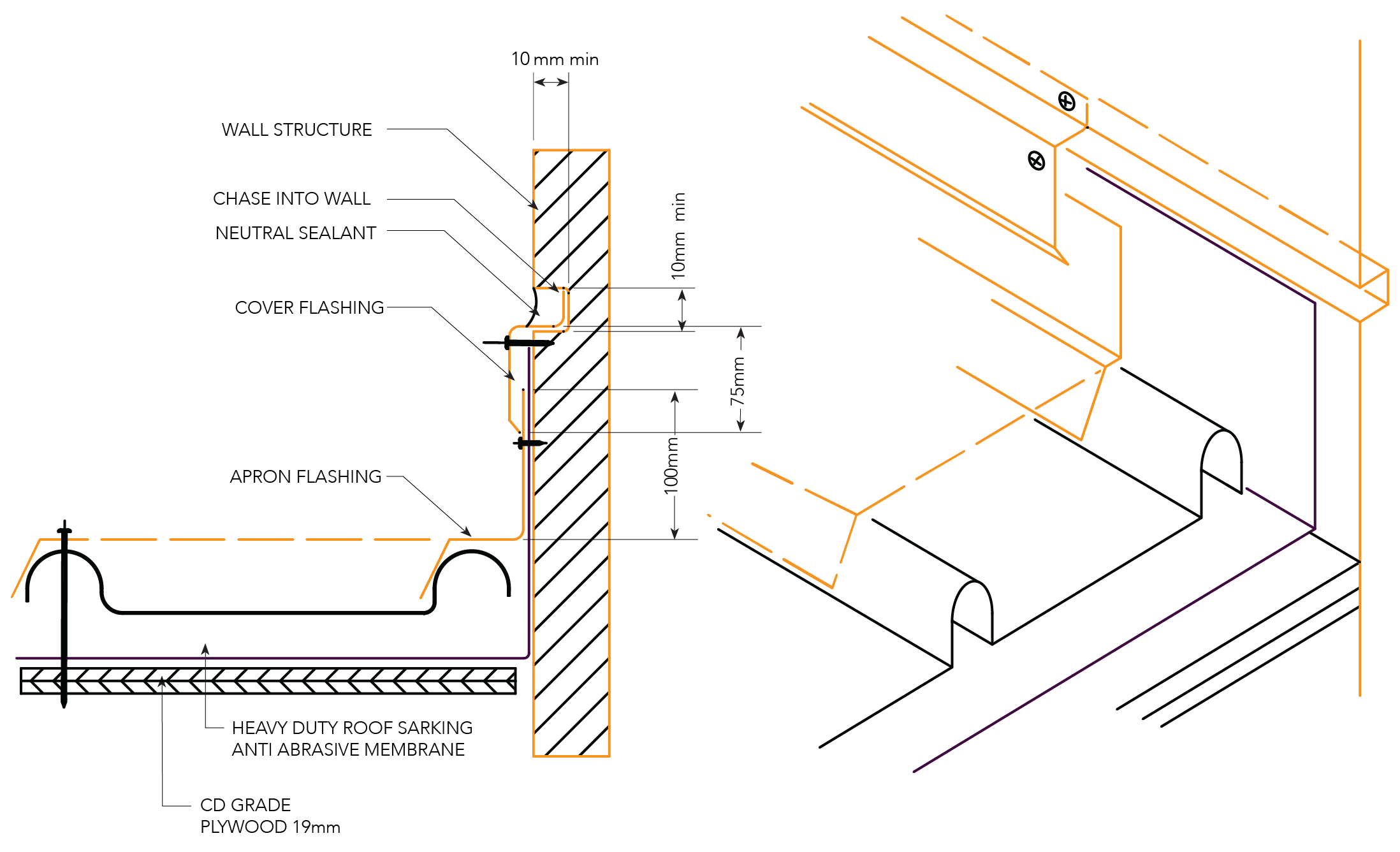

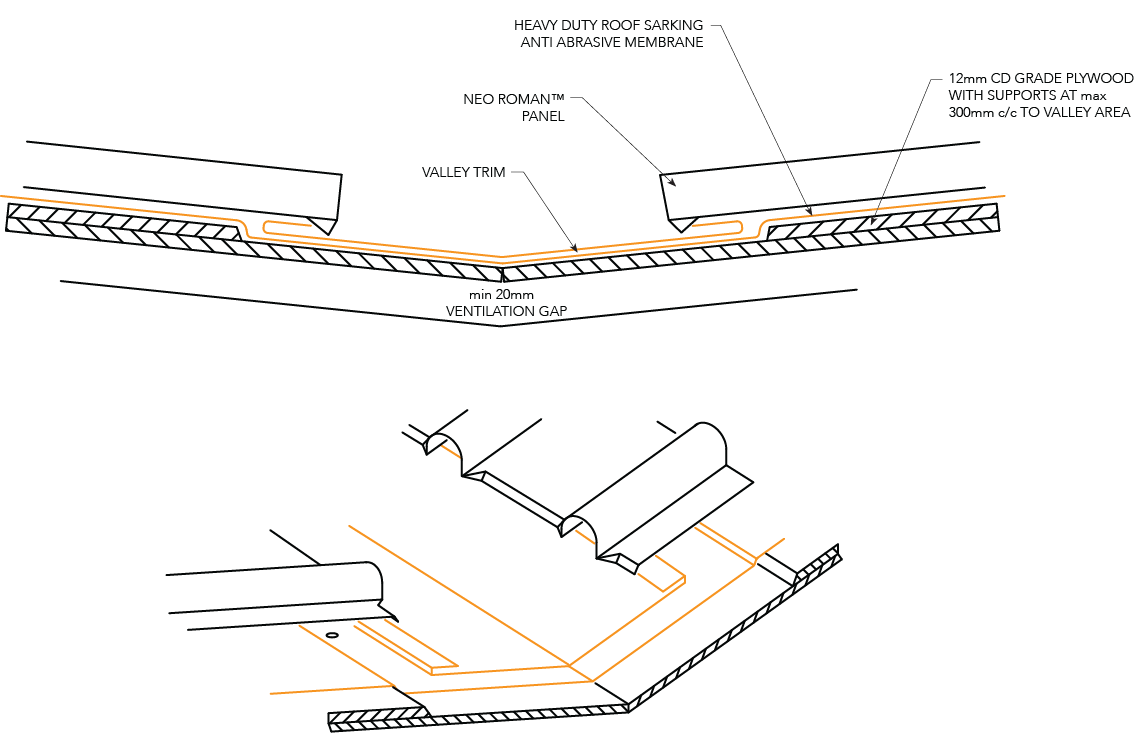

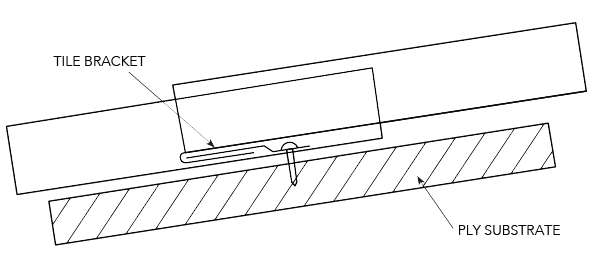

When using Neo Roman™ for a roof cladding a plywood support must be provided. Plywood support should be 19mm thick F11 Structural CD grade with maximum support spacings of 600mm for roofing applications and 15mm F11 Structural CD Grade if used in walling applications. For pitches over ten degrees, in normal conditions, Neo Roman™ can be end lapped, in exposed situations silicon sealing of the laps may be required. Figure NR ID NC 017 shows a typical lap joint for roofs under 10 degrees (minimum pitch of 5°), the respective dimensions are to be determined according to the pitch of the roof and the relative exposure of the site.

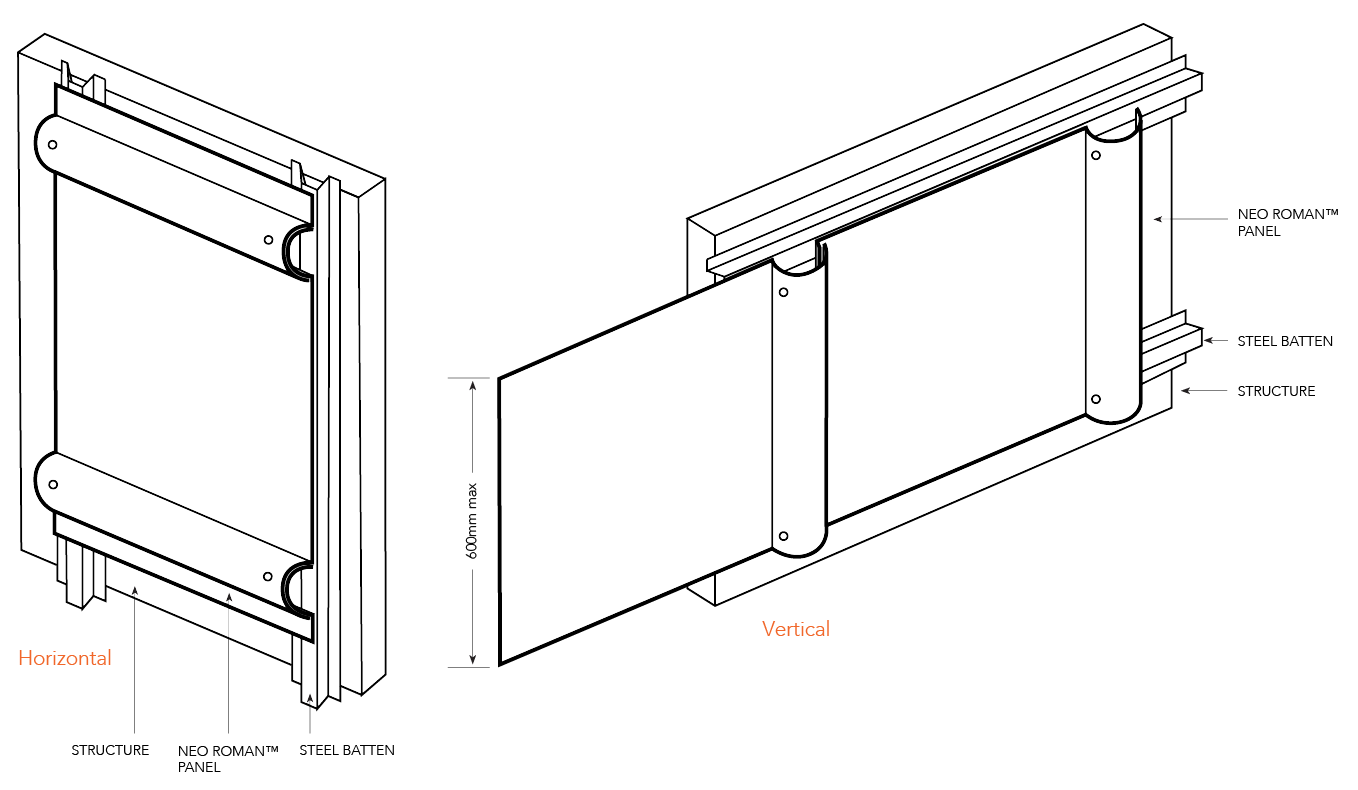

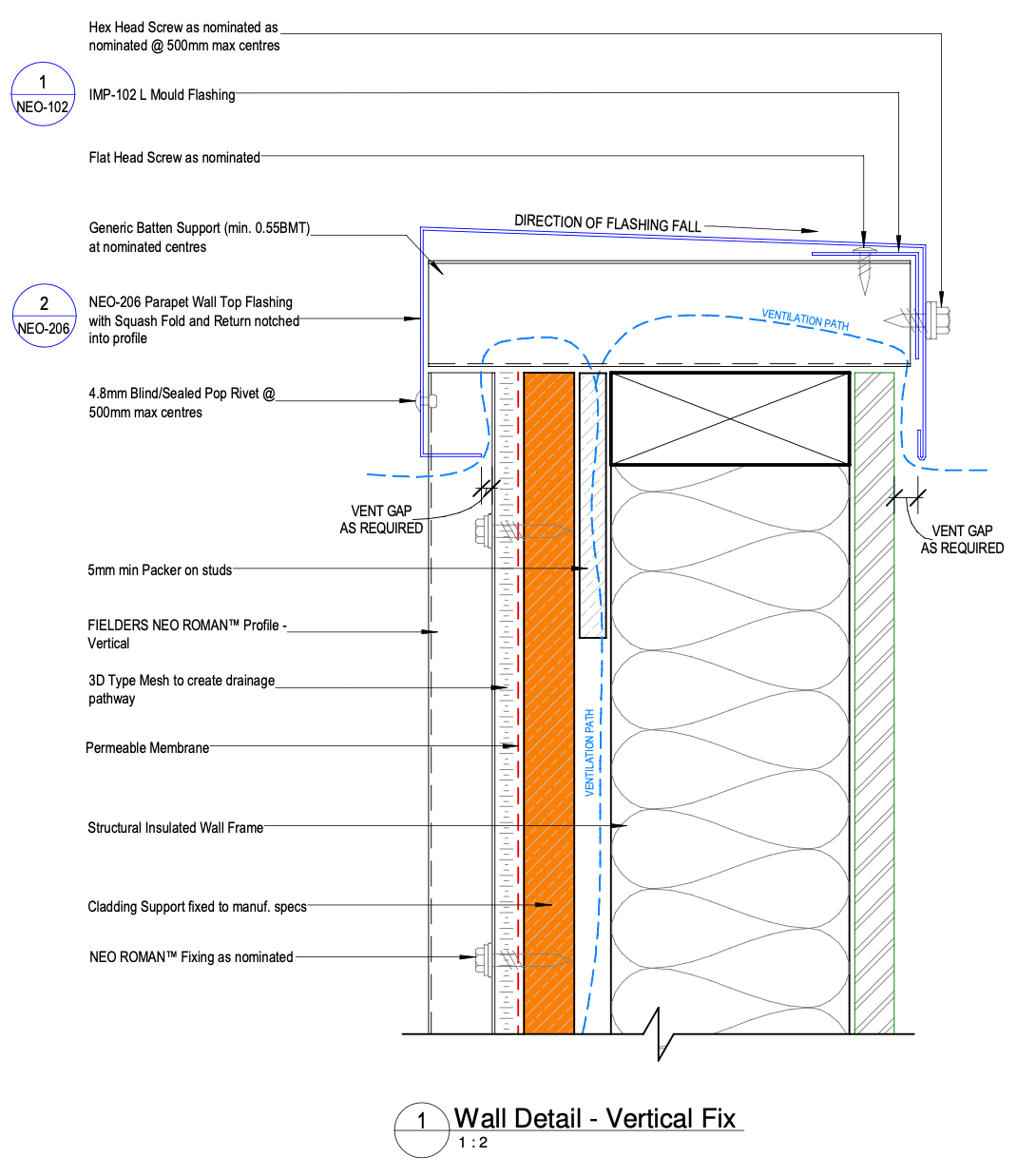

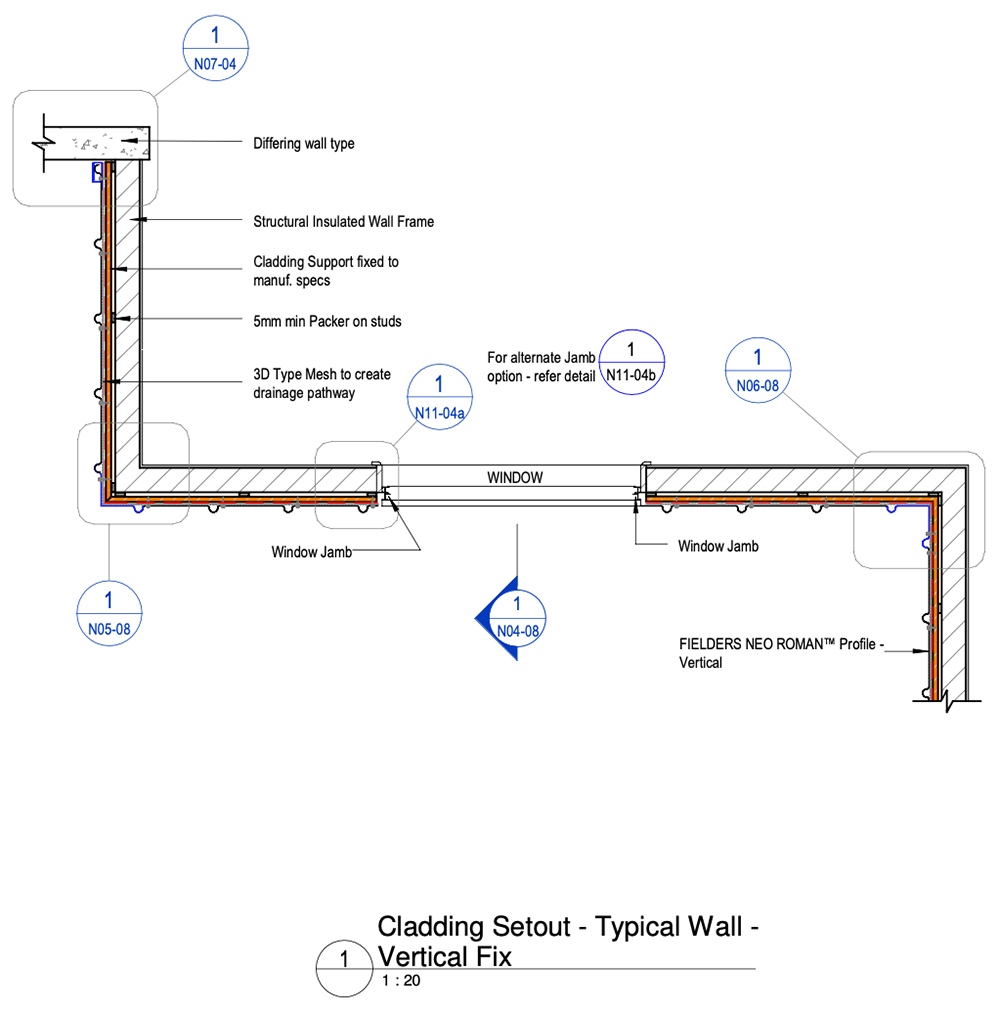

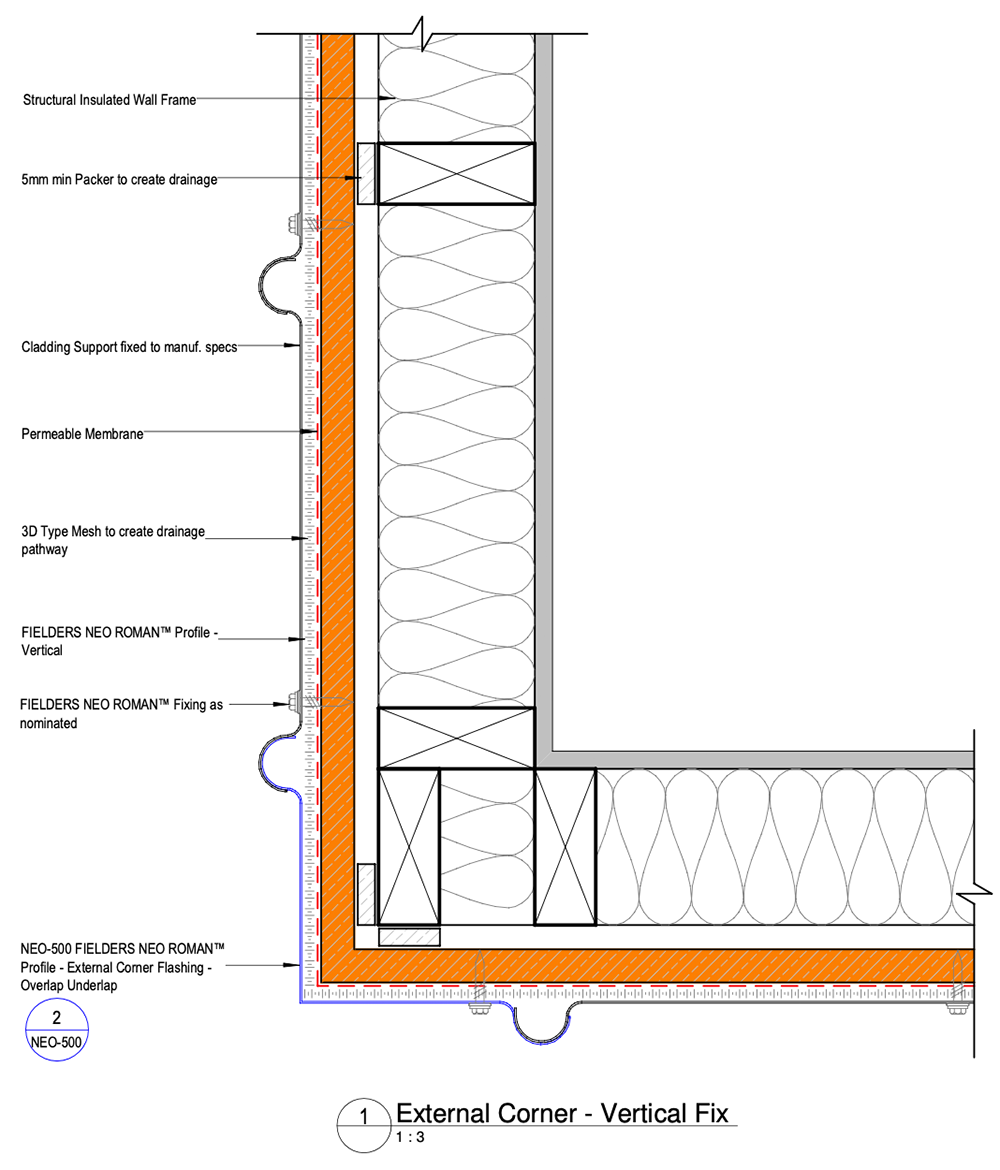

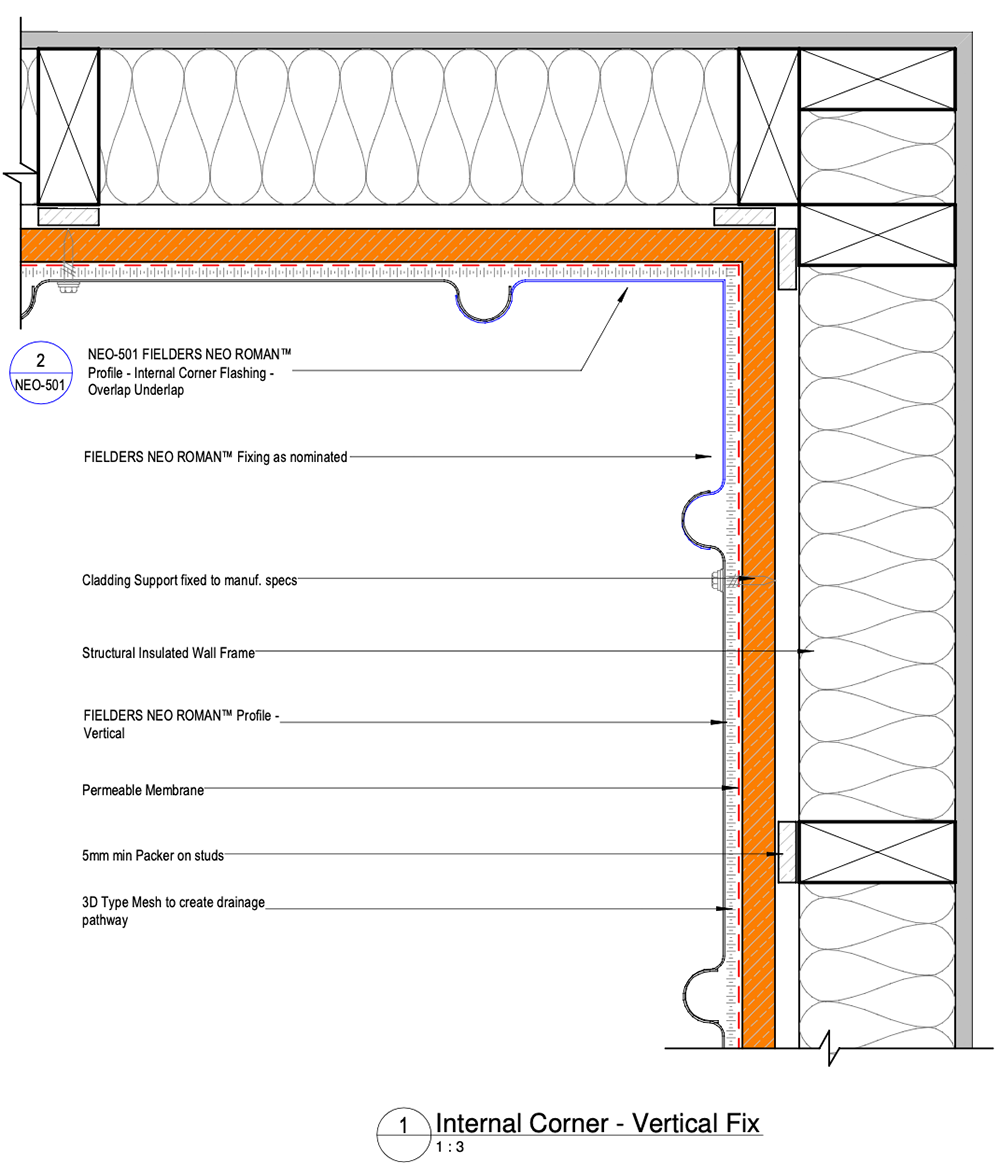

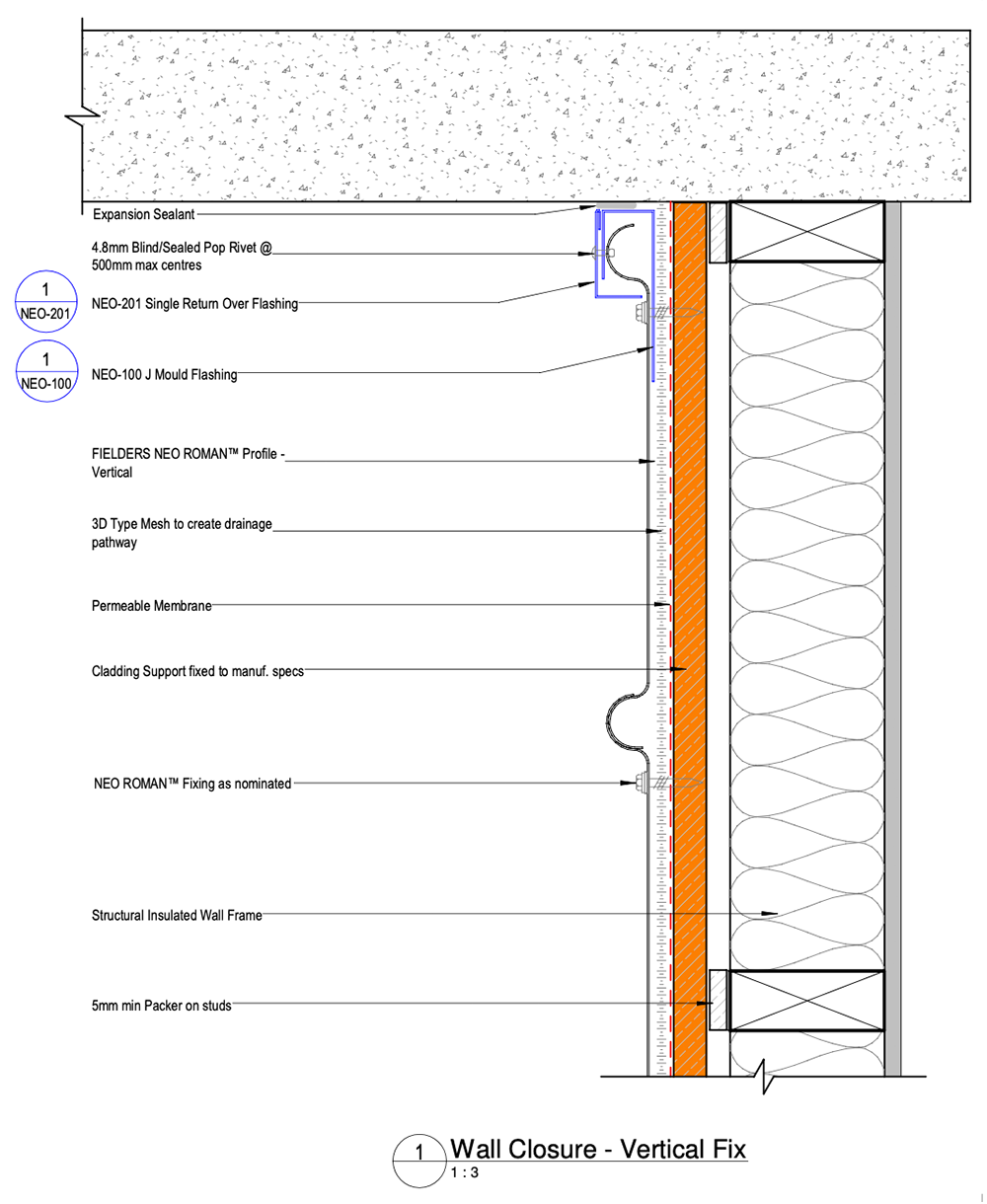

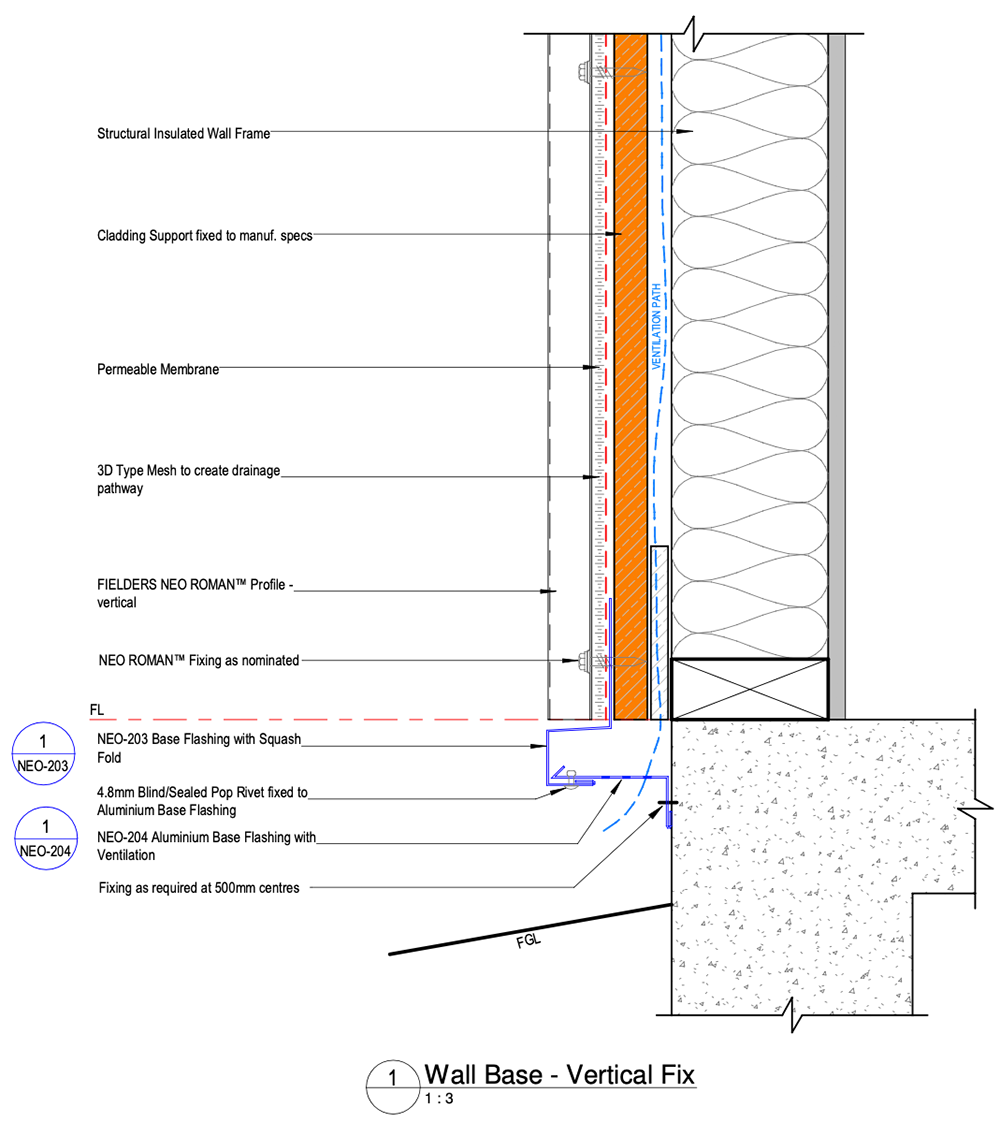

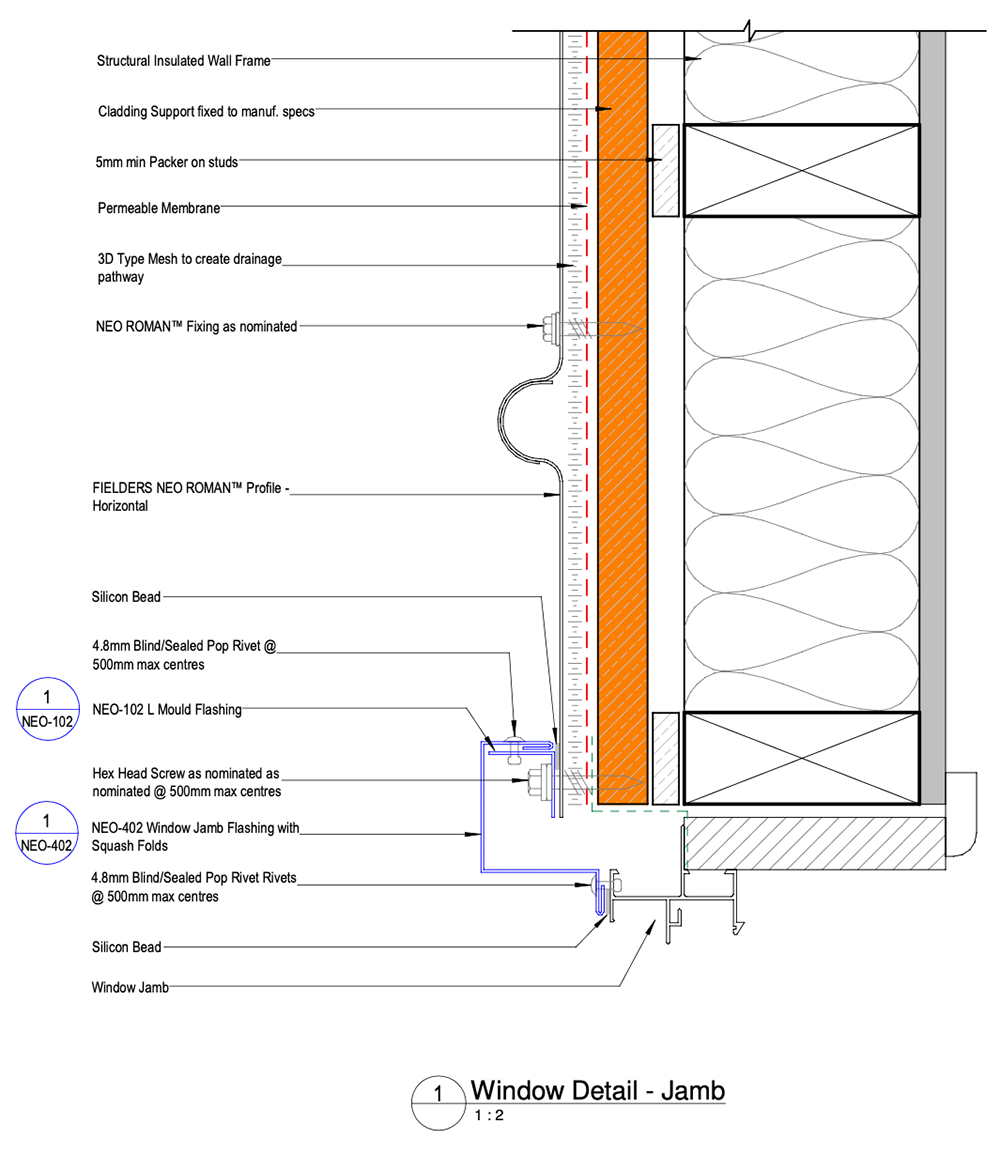

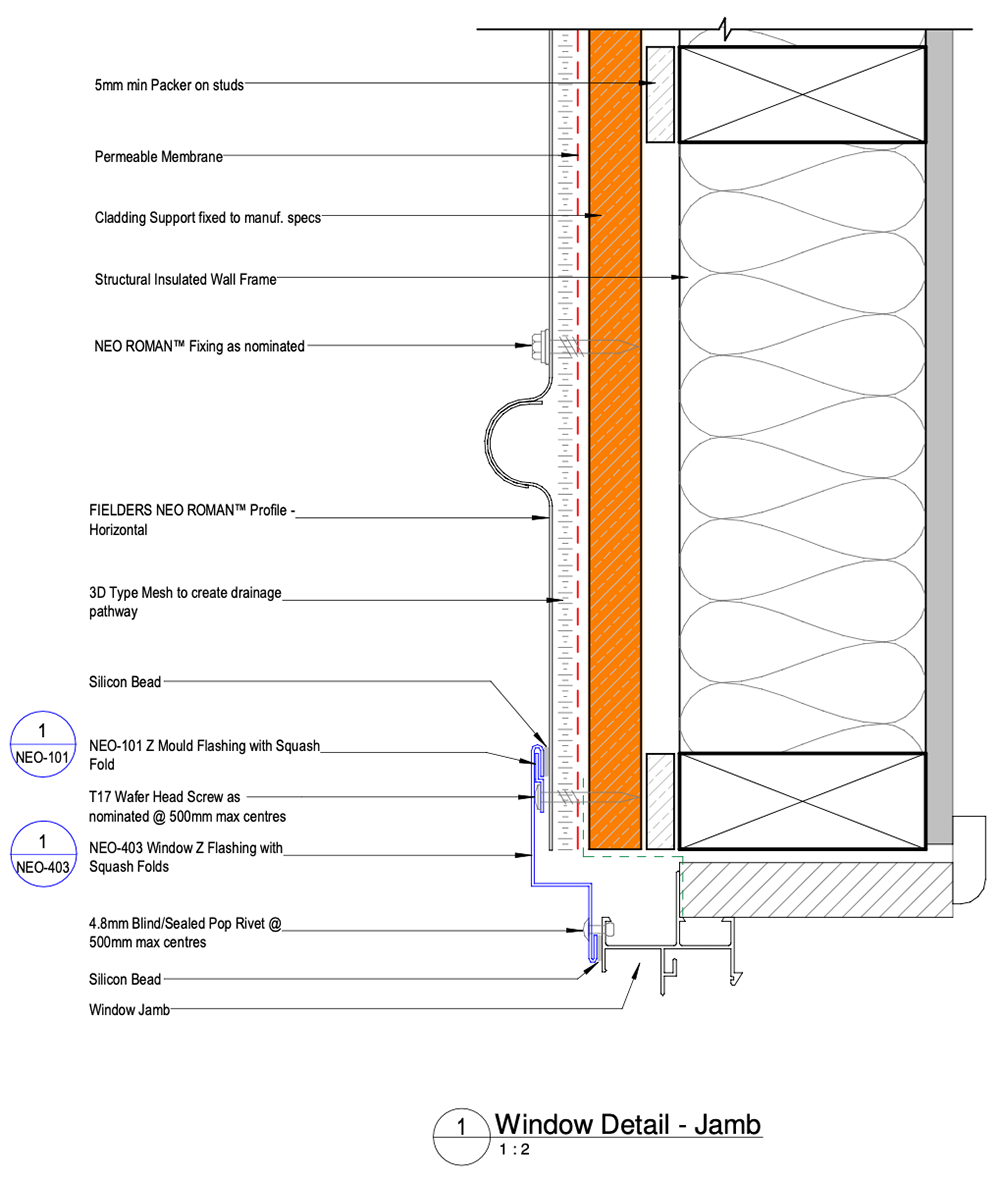

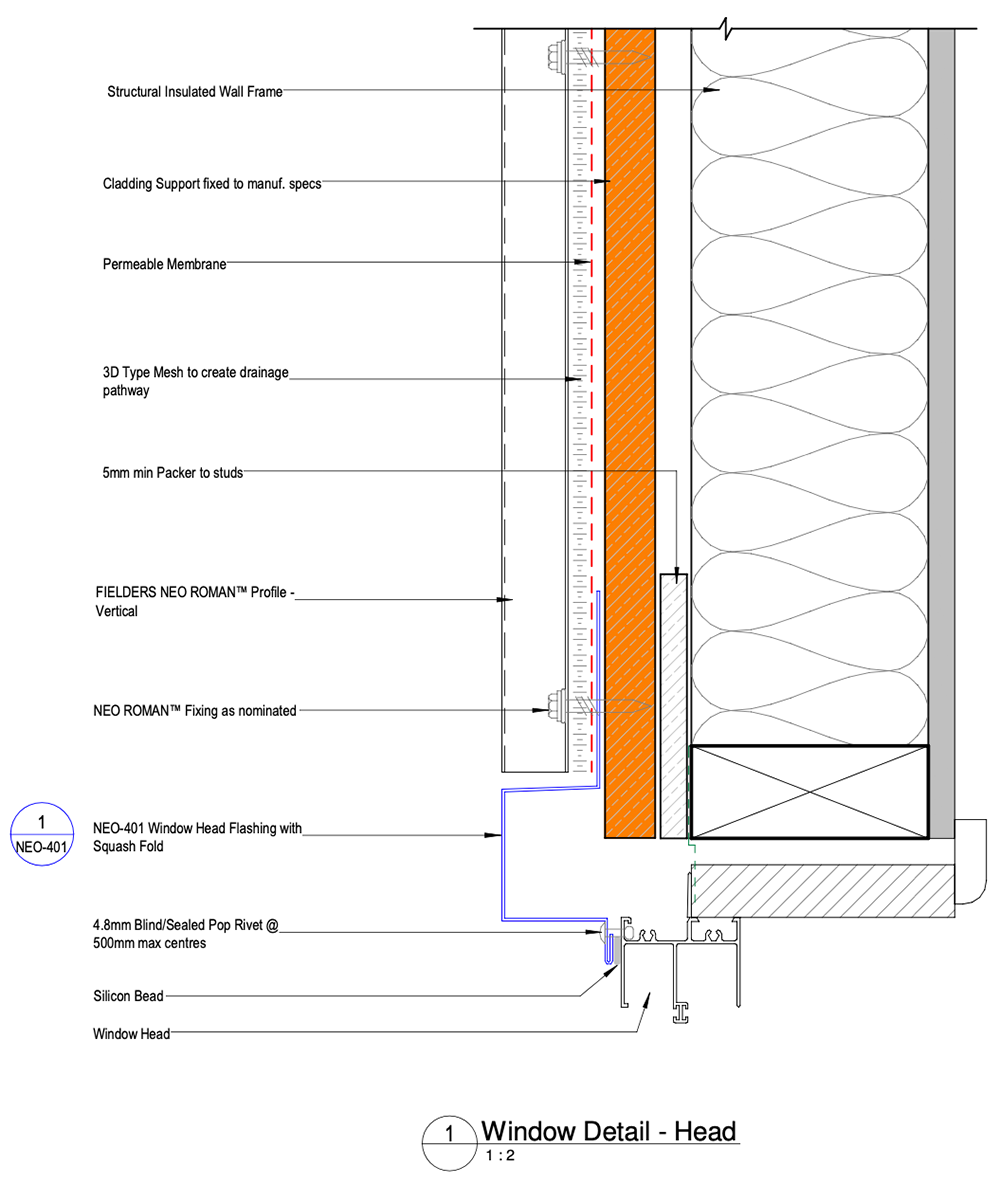

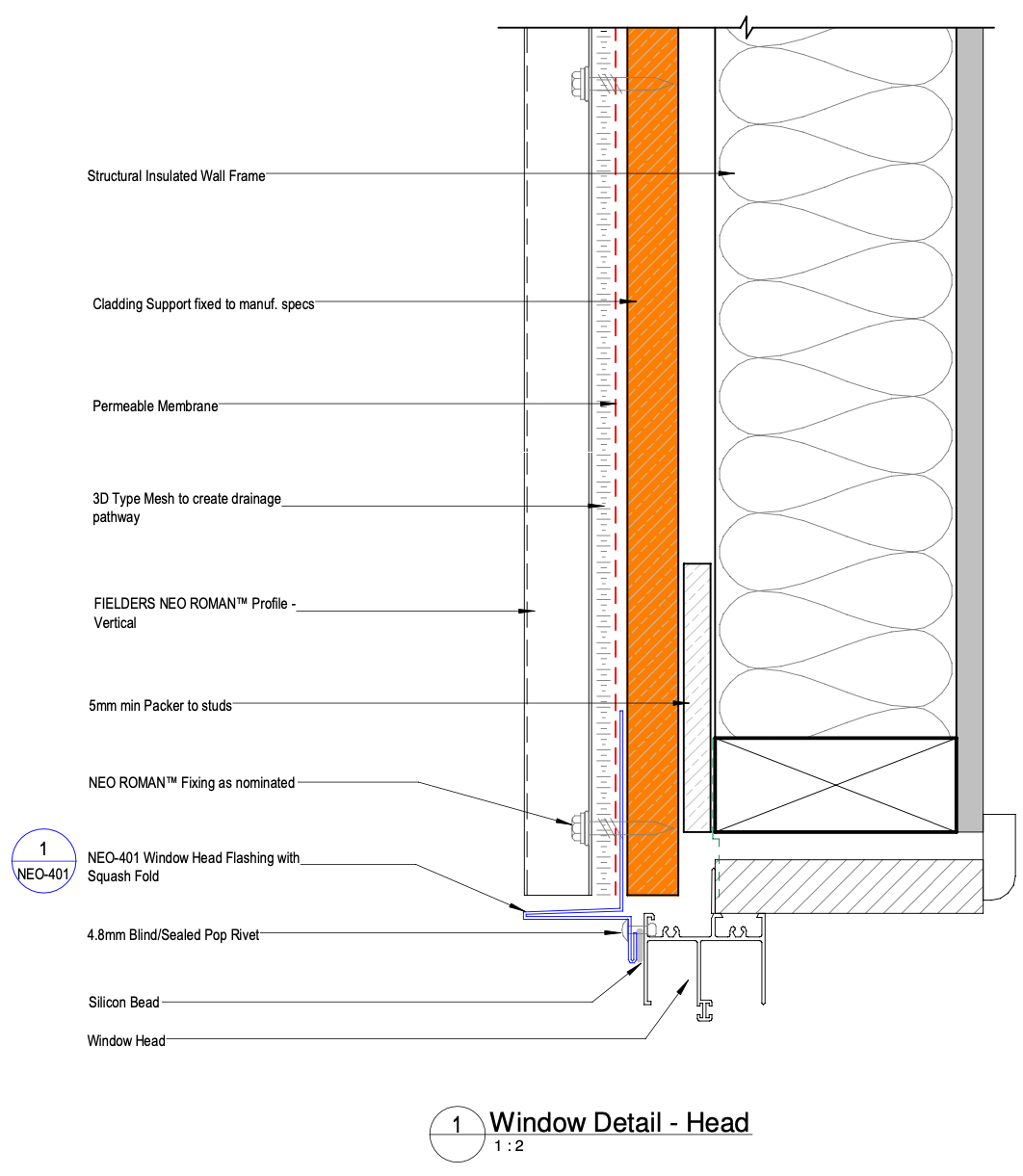

Wall Cladding

When used as walling, if Neo Roman™ 275mm cover is utilised, there is no need for a ply substrate. However, the spacing of the girt should not exceed 600mm to minimise any oil canning. In areas where it is possible for the cladding to be hit, say by shopping trolleys, it is recommended that the ply support is used to minimise any damage to the sheet. Maximum length of the sheet is 4000mm.

Fasteners

Refer to installation details.

Installation Details

A wider range of Construction details covering fixing to ply substrate is available for download at https://specifying.fielders.com.au/downloads.

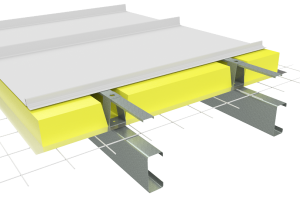

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thicknesses up to 50mm are installed the screws may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed in to. For timber the screw must penetrate into the timber by a minimum of 25mm.

When insulation is required in conjunction with Finesse® profiles Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising any bulging in the profile caused by the insulation.

Insulation blankets and batts can cause wide flat pan cladding to bow out between the supports, between fasteners along the support, or bow the pans. For insulation blankets and batts as well as more dense glass wool and rock wool, and thicker insulation, spacers are recommended.