The architectural aesthetics of the Finesse Architectural Cladding range may be enhanced by its curving capabilities. With the exception of Boulevard®, the Finesse profiles have a varied degree of curving capability and maybe Roll Curved, Sprung Arch Curved or Transverse Sprung Curved as per Table below.

Curving Capability

| Longitudinal Curving- Min Radi | Min Radi Transverse (Walling) | ||||

| Profile | Roll Curve (m) (Convex) | Sprung curved (Convex-Concave) | Max support at Min Radius | Transverse Spring Arched for (m) Convex/ Concave | Max Support at Min Radius (m) - Transverse Spring Curve |

| Shadowline 300 | N/A | 26 | 1600 | N/A | N/A |

| Shadowline Tapered | N/A | 20 | 1200 | N/A | N/A |

| Prominence™ | N/A | N/A | N/A | 1.5* | Full ply support |

| Grandeur® | 1.5 (0.6 for aluminium) | 50 | Full ply support with fixed clips at 150mm c/c throughout curve | 1.5 | Full ply support with spacings as per fig GR ID NC 001 |

| Boulevard | N/A | N/A | N/A | 1.8/2.8** | Curved battens (0.55mm bmt min) @ 600mm c/c |

| Neo Roman | N/A | N/A | N/A | 1.5 | Full ply support |

*For Transverse Convex Walling applications Prominence™ ribs should be pop riveted as per figure 1 at max 500mm c/c

**Special care is required in concave applications to avoid paint damage to recess joints whilst installing fixing screws

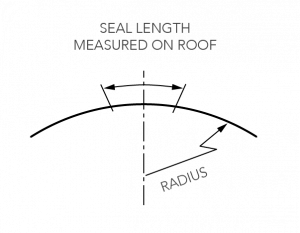

Sprung Curved Roofs

For Sprung Curved roofing applications the crest of the roof becomes flat which will be lower that the min roof pitch. Therefore side-laps should be sealed over the crest of the arch until there is sufficient pitch to give adequate drainage. The length of seals generally calculated as 0.035 x radius as shown at Figure 2.

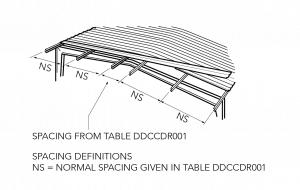

Consideration needs to be given to support spacings throughout the sprung curved section of the roof. Min support spacings are outlined in Table DD CC DR 001 and should be applied as per Figure 3.

Roll Curved Finesse

Grandeur® is the only Finesse profile available as roll curved solution and be curved to a radius of 1.5m in steel (or 0.6 for aluminium applications). Because of the spacing of curving rolls, there is usually a straight portion at the end of the sheet beyond the curve (often 500). Allow for this in your design. It can be trimmed off if necessary. If a roll curved section of cladding is to be joined to a straight section, ensure you order the curved and straight sheets at the same time, asking for them to be matched in production to ensure a quality end-lap.

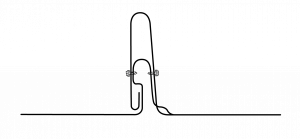

Capped Bent Ribbed Roof

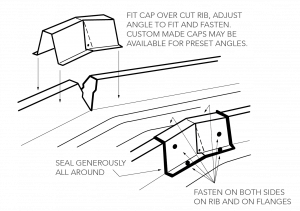

Another method for roofs with a pitch outside the spring curving range is the capped bent ribbed roof. Finesse cladding can be used in continuous lengths from eave to eave by cutting the ribs and bending the pans at the ridgeline. The same process is used on Mansard roofs. Caps are fitted over the cut ribs, which open up when the pans are bent. Fitting the rib caps can be time-consuming and care must be taken with sealing to avoid any possibility of leakage. The ribs must be cut squarely, with a metal cutting blade in a power saw, set to the depth of the rib minus 2mm. Steel Caps are then manufactured and installed as shown in Figure 4.1.3. A neutral-cure silicon sealant should be used.

Please note that Neo Roman® is not suitable for capped bent ribbed roof applications.

Figure 4.1.3