Barrel Rolling, Re-creating history

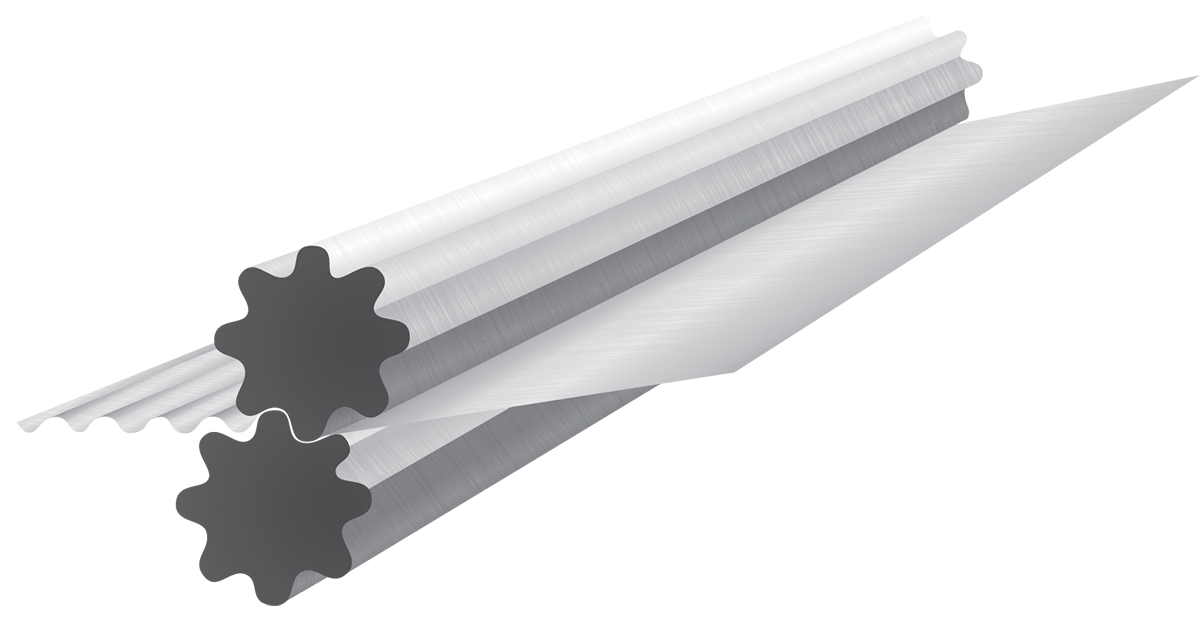

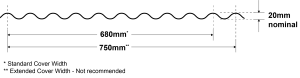

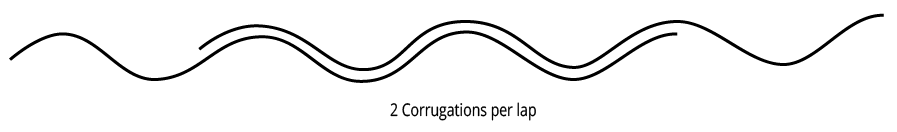

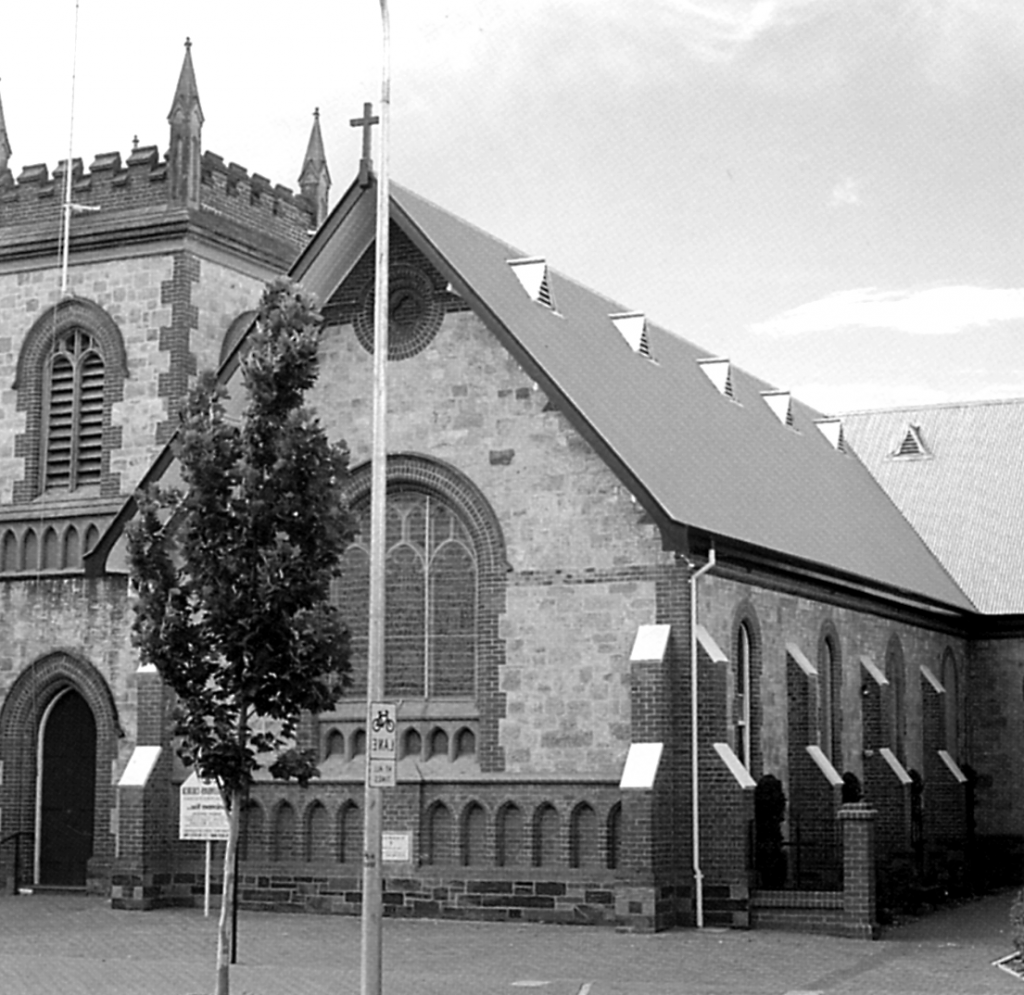

Our beautifully restored 75 year old barrel press rolls the steel to create authentic bespoke deep corrugations (19mm – ¾”), compared with 16mm for modern roll formers, and a cover of 670mm with a double rib overlap. This authentic profile product is called ‘3/4” corrugated’ and is available in short sheets up to 10 feet (3.05m) in length to perfectly match those on century-old buildings.

*740mm cover maybe be achieved using a single rib overlap but this is not recommended.

An Extra Ounce of Protection

Back in 1900 when Fielders® was first established, galvanised roofing came in two weights:

- light Z275 (one ounce per square foot)

- heavy Z600 (two ounces per square foot).

In the main, the roof sheeting and gutters of quality buildings (the ones that have probably survived the century) were given the heavier, longer lasting two ounce coating, which was double-smelted and often imported.

As time went by, companies stopped making this double coated roofing as builders economised with the more rust-prone light coating or they compromised with the Z450 one and a half ounce product. Needless to say, neither gave a satisfactory result, nor one that lasted as long. This, you could say, galvanised us into action.

Brand New, Good Old-fashioned Roofs

Today this means that the 100% Australian-owned Fielders® is back in the business of making heritage roofing and guttering. Fielders® is the only Australian company that makes roofing and guttering from 100% genuine double thickness Z600 galvanised BlueScope steel.

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thicknesses up to 50mm are installed the screws detailed in Table H RF NC 001 may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed to. For timber, the screw must penetrate the timber as much as the screws detailed in Table H RF NC 001 do without insulation. For insulation thicknesses greater than 50mm Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising and bulging in the profile caused by the insulation.

Fastening

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those compatible with the roofing material should be used for its fastening.

Recommended Fasteners

| Fixing Supports | Crest Fixing | Valley Fixing (Wall only) | Side Lap Fixing |

| Steel (1.0 to 3.5mm) | 12g-14x35mm Hex Head Tek Screws with seal | 10g-16x16mm Hex Head Tek Screws with seal | 10g-16x16mm Hex Head Tek Screws with seal |

| Timber Hardwood | M6-11x50mm Hex Head RoofZips with HiGrip & seal | M6-11x25mm Hex Head RoofZips with seal | |

| Timber Softwood | M6-11x50mm Hex Head RoofZips with HiGrip & seal | M6-11x25mm Hex Head RoofZips with seal | |

| Metal Battens (0.55 to 1.0mm) | M6-11x50mm Hex Head RoofZips with HiGrip & seal | 15g-15x25mm Hex Head Metal Batten Tek Screws with seal |

Fastener Spacings - Non Cyclonic

Crest Fastener Location

5 Fasteners per sheet - end supports and end laps.

3 Fasteners per sheet - Internal supports.

Roofing should be lapped away from the prevailing weather.

Valley Fastener Location (Wall Only)

5 Fasteners per sheet - End supports and end laps.

3 Fasteners per sheet - Internal supports.

Table H FS NC 003

Note:

1. All fasteners used externally should be fitted with an EPDM seal (washer).

2. Do not use punches to form fastener holes.

Heritage Barrel Rolled Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

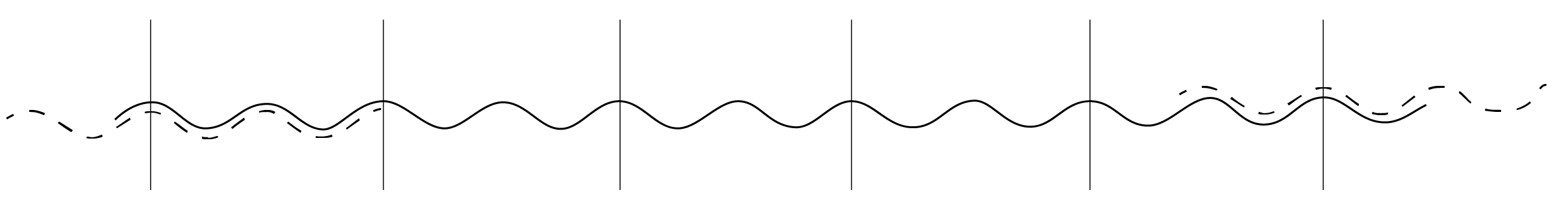

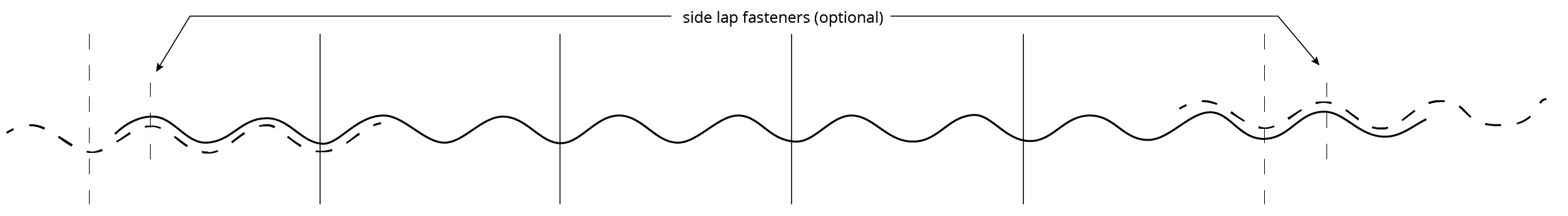

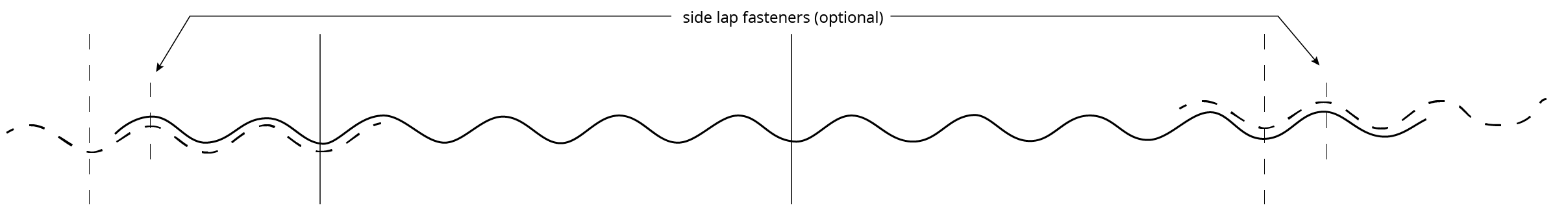

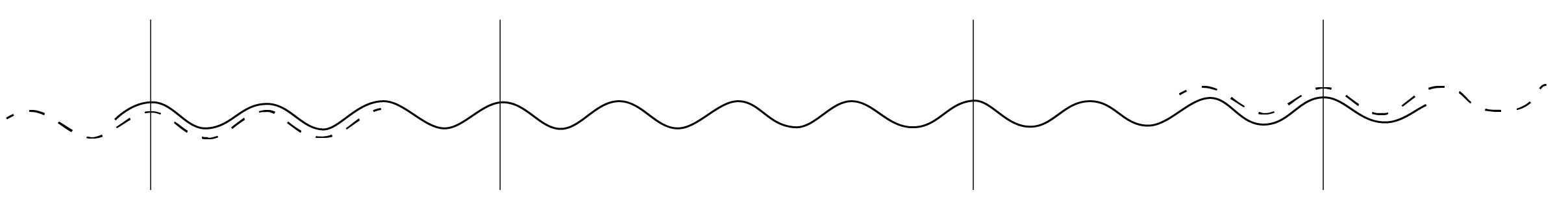

Figure H NC Corrugation Laps 003

Side Lap Fixing

It may be necessary to use side lap fasteners at mid spans when using maximum spans. These will help to hold the sheet firmly in place and maintain a weather-proof joint.

Additional Heritage Products

- Mini-Flute

- Ridge, valleys, barge rolls

- Full range of gutter profiles and downpipes (see “Guttering and Facias”)

- Rainheads, vents, dormers &cupolas (see “Rainheads and Vents”)

An Old-fashioned Guarantee as Well

An Old-fashioned Guarantee as well Fielders® Heritage Barrel rolled is backed with a warranty of up to 15 years against corrosion. So if you want your restoration to last another hundred years, you’d better specify Fielders® double-thickness Heritage Z600 galvanised roofing.