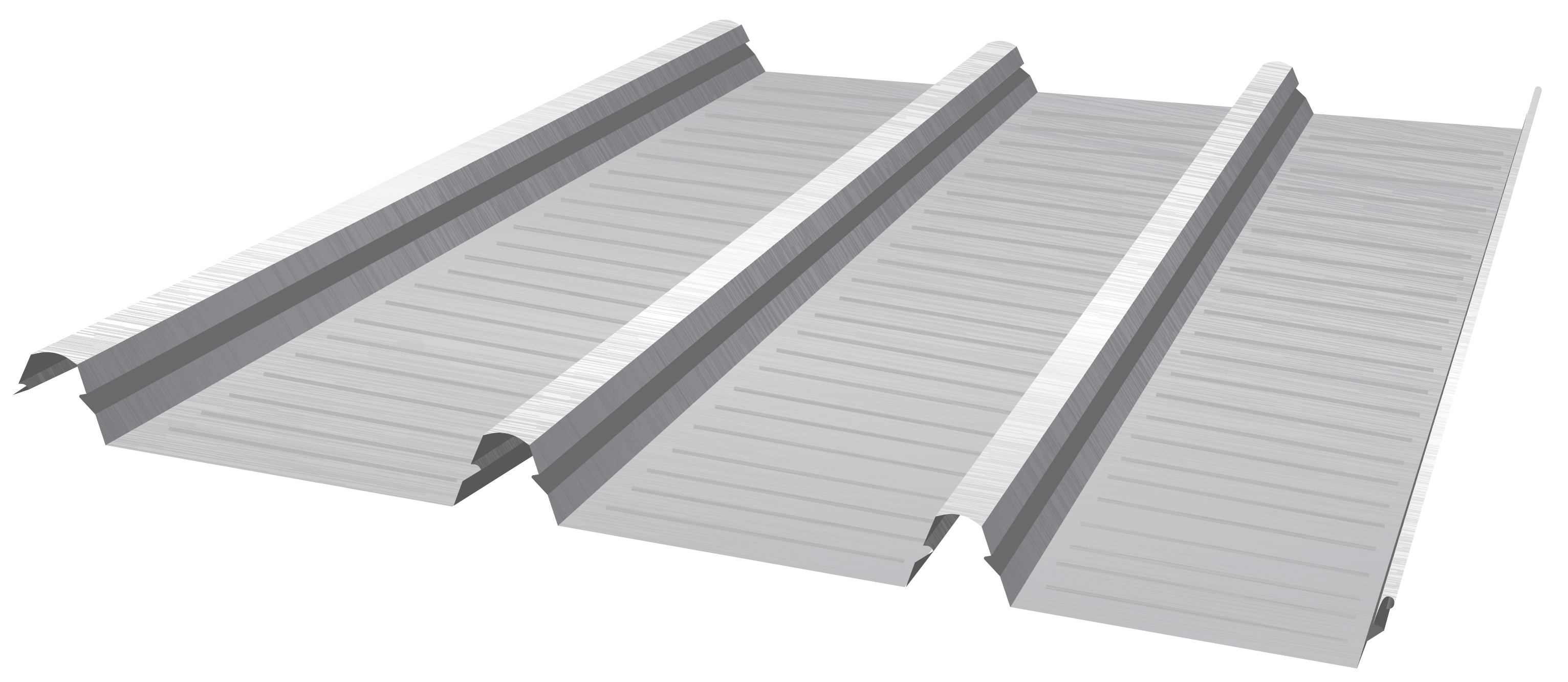

KingKlip® 700 Non-Cyclonic for NSW | VIC

Material Specifications

| Property | Notes | |||

| Base Metal Thickness (mm) | 0.42 | 0.48 | BMT | |

| Mass / Unit Length | ZINCALUME® | 3.23 | 3.67 | kg/m |

| COLORBOND® | 3.26 | 3.70 | ||

| Mass / Unit Area | ZINCALUME® | 4.61 | 5.24 | kg/m2 |

| COLORBOND® | 4.65* | 5.28* |

||

| Minimum Yield Strength | G550 | Base Steel Designation | ||

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME®) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 | ||

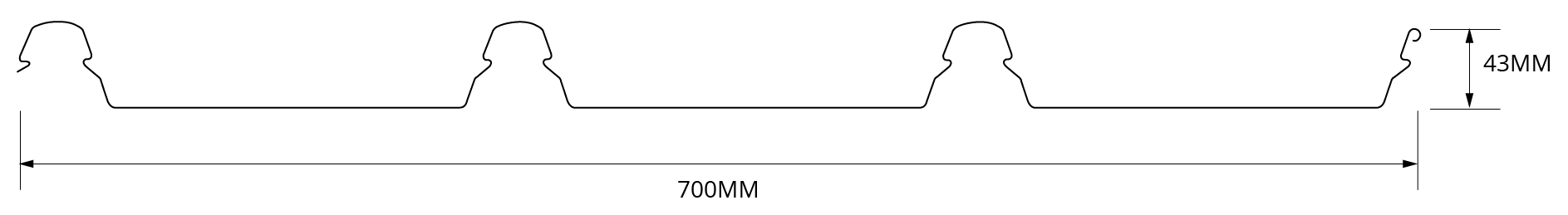

| Coverage (mm) | 700 | |||

| Tolerance | Length: +0mm, -15mm; Width: +4mm, -4mm | |||

Note:

- KingKlip 700® is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

Rainfall Capacity

For further information, please refer to sections "Rainfall Intensity" and "Water Carrying Capacity and Rainwater Run-Off".

Non-Cyclonic Load Span Tables

The design pressures and allowable spans have been determined from tests carried out in accordance with the following Australian Standards: AS 1562.1:1992, “Design and installation of sheet roof and wall cladding – Metal” and AS 4040:1992, “Methods of testing sheet roof and wall cladding”.

All values are applicable for fixing into a minimum steel support thickness of 1.5mm.

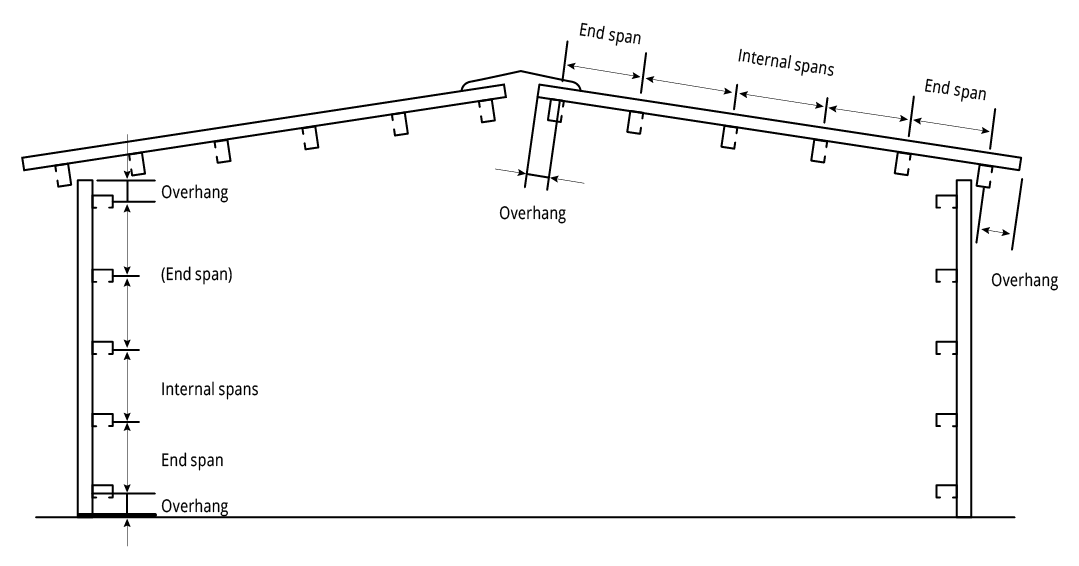

Figure KK NC 002 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Clip

Wind Pressure Capacities: 0.42mm BMT

| Span (mm) | End Span | Internal Span | ||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 900 | 3.05 | 5.55 | 2.90 | 5.40 |

| 1200 | 2.73 | 4.30 | 2.64 | 4.60 |

| 1500 | 2.40 | 3.35 | 2.39 | 3.90 |

| 1800 | 2.02 | 2.75 | 2.16 | 3.25 |

| 2100 | 1.64 | 2.55 | 1.94 | 2.75 |

| 2400 | 1.32 | 2.40 | 1.74 | 2.40 |

| 2700 | 1.07 | 2.20 | 1.38 | 2.00 |

| 3000 | 0.91 | 1.85 | 1.58 | 2.30 |

Note:

- Values are based on fixing into steel supports with a minimum thickness of 1.5mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Wind Pressure Capacities: 0.48mm BMT

| Span (mm) | End Span | Internal Span | ||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 900 | 3.81 | 6.30 | 3.76 | 6.35 |

| 1200 | 3.34 | 5.10 | 3.32 | 5.55 |

| 1500 | 2.88 | 4.15 | 2.91 | 4.80 |

| 1800 | 2.43 | 3.55 | 2.54 | 4.10 |

| 2100 | 2.02 | 3.15 | 2.24 | 3.60 |

| 2400 | 1.67 | 2.85 | 2.01 | 3.20 |

| 2700 | 1.38 | 2.50 | 1.84 | 2.85 |

| 3000 | 1.15 | 2.20 | 1.68 | 2.60 |

Note:

- Values are based on fixing into steel supports with a minimum thickness of 1.5mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability.

Maximum Recommended Roof Cladding Span Non-Cyclonic

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | |

| End (mm) | Internal (mm) | ||

| A & B | 0.42 | 1750 | 2200 |

| 0.48 | 2350 | 2800 | |

Importance Level 2

Max. Roof Height = 10m External

Pressure Coefficient

Cpe = -0.65 (walling)

Cpe = -0.9 (roofing)

Internal Pressure Coefficient

Cpi = 0.2

Local Pressure Factor,

Kl = 2.0 (end & single spans)

Kl = 1.0 (internal spans)

Table KK RS NC 002A - KingKlip 700® Non-Cyclonic

Notes:

- For roofs: the data are based on foot-traffic loading.

- Table data are based on supports of 1mm BMT.

Maximum Recommended Wall Cladding Span Non-Cyclonic

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | |

| End (mm) | Internal (mm) | ||

| B | 0.42 | 3000* | 3000* |

| 0.48 | 3000 | 3000* | |

Importance Level 2

Max. Roof Height = 10m External

Pressure Coefficient

Cpe = -0.65 (walling)

Cpe = -0.9 (roofing)

Internal Pressure Coefficient

Cpi = 0.2

Local Pressure Factor,

Kl = 2.0 (end & single spans)

Kl = 1.0 (internal spans)

Table KK RS NC 001B - KingKlip 700® Non-Cyclonic

Notes:

- For walls: the data are based on pressures for transverse fluted material.

- Table data are based on supports of 1mm BMT.

- *Spans in excess of 3000mm may be available subject to enquiry.

- Wall applications or long spans require particular attention to installation practice.

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thickness up to 50mm are installed the screws detailed in Table KK RF NC 001 may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed in to. For timber the screw must penetrate the timber as much as the screws detailed in Table KK RF NC 001 do without insulation. For insulation thicknesses greater than 50mm Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising any bulging in the profile caused by the insulation. Please contact your local Fielders Representative to determine the most suitable spacer bracket for your project.

Fasteners - Clip Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Crest or Pan Fixing

KingKlip 700® can be crest fixed to timber or steel supports. Fasteners should not be located less than 30mm from the ends of the sheets. Contact your local Fielders® Representative for capacity information.

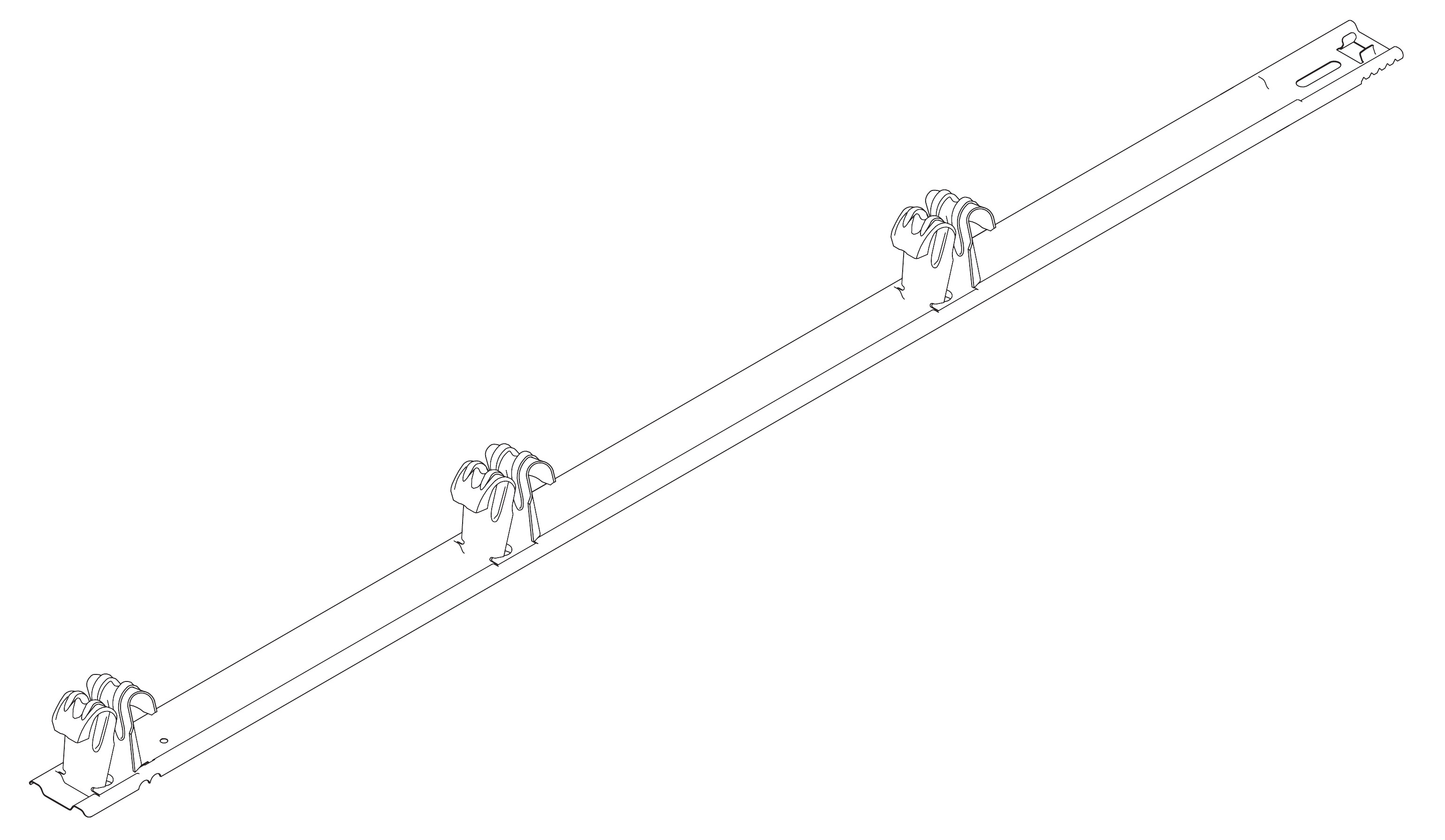

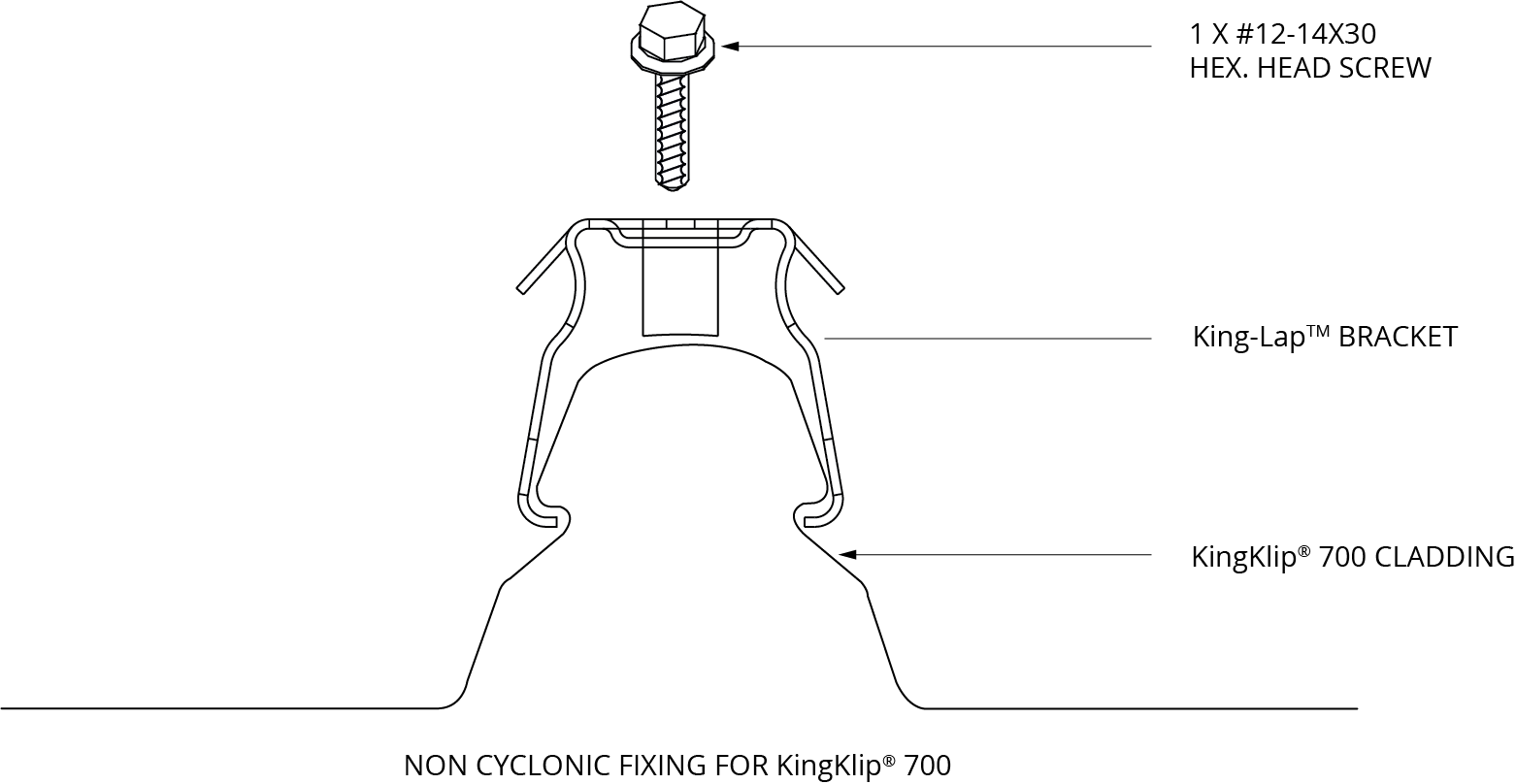

Concealed Fix Clipping System

Figure KK MKII KingKlip® NY 001 - Concealed Fix Clipping System

Recommended Fasteners Concealed-Fixed

| Supports | Clip Fixed |

| Fix to Steel Single thickness steel ≥1.0mm BMT up to 3.0mm BMT | RoofZips M6-11x25 |

| Fix to Steel Total Lapped thicknesses of ≥1.0mm BMT up to 3.8mm BMT | 12-14x20, Metal Teks, HH |

| Fix to Timber Hardwood (J1-J3) | 12-11x25, Type 17, HH |

| Timber Softwood (J4) | 12-11x45, Type 17, HH or RoofZips M6-11x25 |

Notes:

1. Use three (3) fasteners per clip

2. Recommended fasteners shown in Table KK RF NC 001 are for construction without insulation

KingKlip® 700 Installation Procedure

Refer to "Maintenance and Care" for general handling instructions.

PREPARATION

Before starting work ensure that:

- check flatness, slope and overhang

- orient the sheets before lifting

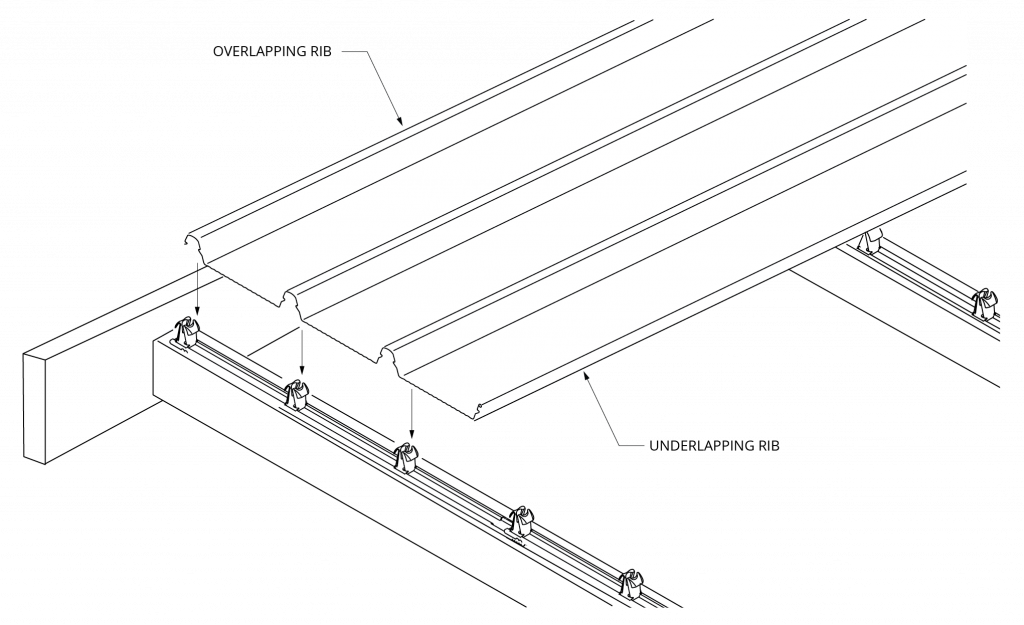

- note the overlapping rib is towards the end of the building where you start

- check that the overhang of the sheets from the clips, at both eaves and ridge, is not less than the minimum permitted.

- the first and the last supports and clips should be at least 75mm from each end of the sheet to keep maximum holding power.

- Make any necessary adjustments before you start laying sheets because they will be difficult to rectify later.

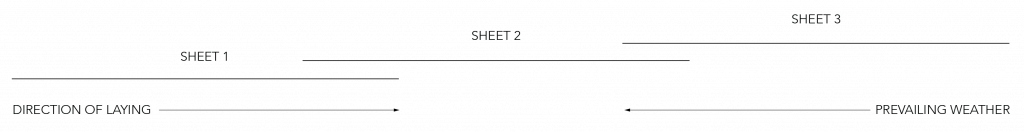

ORIENT SHEETS BEFORE LIFTING

Consider which end of the building is best to start from. For maximum weather-tightness, start laying sheets from the end of the building that will be downwind of the worst-anticipated or prevailing weather (Figure 1). It is much easier and safer to turn sheets on the ground than up on the roof. Before lifting sheets on to the roof, check that they are the correct way up and the overlapping side is towards the edge of the roof from which installation will start. Place bundles of sheets over or near firm supports, not at mid span of roof members.

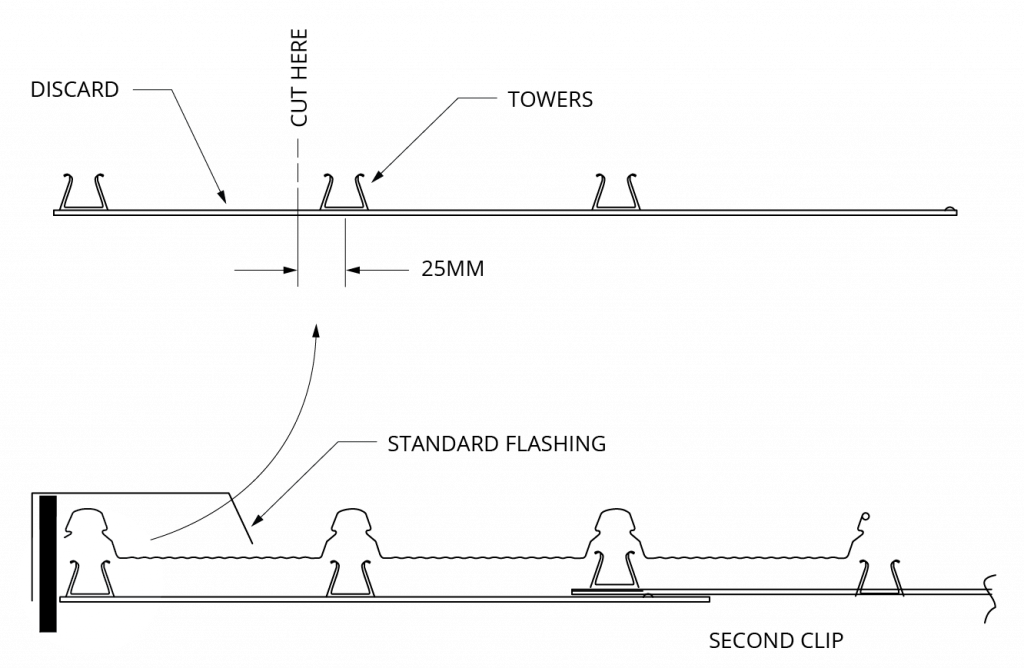

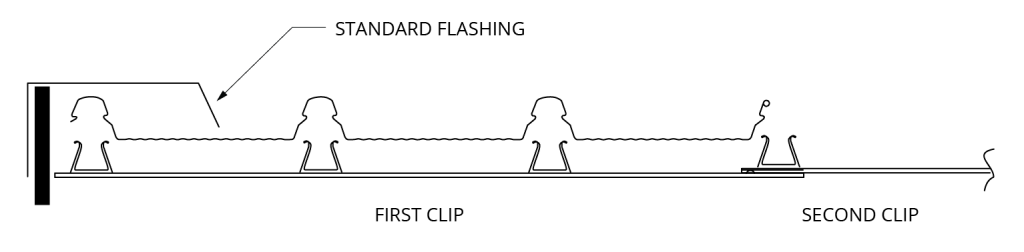

Starting method 1.

Cut the 1st clip 25mm from the centre of the second tower (as shown). The first tower on the cut clip locates in the 1st rib of the first sheet (Figure 2) but you must fix two clips at the start.

Starting method 2.

The first tower on the first clip locates in the first rib of the first sheet (Figure 2). The clip fixes the edge of the first sheet.

KINGKLIP® 700 INSTALLATION

Step 1

Lay and fix wire mesh to the supports and glass wool insulation in accordance with the appropriate building requirements.

Step 2

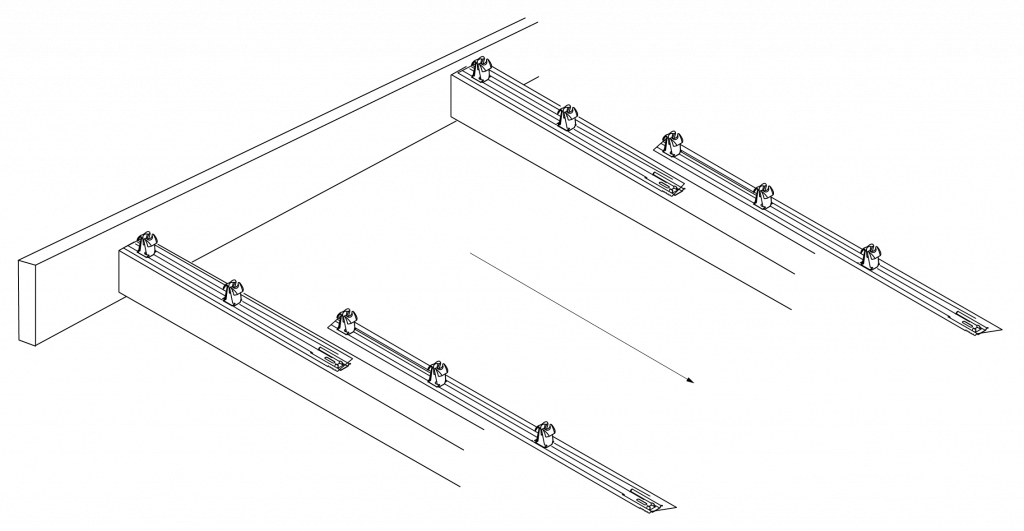

Position the first clips on each support by placing onto the support nearest the roof edge (Figure 3).

Step 3

Fix the first clip on the support so they point in the direction of laying. Ensure the clip is 90 degrees to the edge of the sheet.

Step 4

Align the clips using a string line (or the first sheet as a straight edge) to align the clips as you fix a clip to each support working towards the high end of the roof.

Step 5

Drive hex-head screws through the top of the clip, into the support.

Step 6

Work along the edge of the roof ensuring it aligns correctly at its ends in relation to the gutter and ridge (or parapet or transverse wall).

Step 7

Position the first sheet so that it overhangs the desired amount (usually 50mm) to the gutter. It is important to ensure this first sheet is placed square to adjacent edges (Figure 4).

Step 8

Engage the sheet with clips using vertical foot pressure on all the ribs over each clip.

Step 9

Fix the next row of clips, one to each support with the slots and tabs engaged. Be sure the clip is 90 degrees to the edge of the sheet. It is good practice to bend down the tabs once engaged. This can be done with the bit of a screw gun.

Step 10

As before, place the next sheet over its clips ensuring you also engage the edge of the preceding sheet.

Step 11

Accurately position the sheet so that it overhangs the desired amount into the gutter. It is important that you keep the gutter-end of all sheets in a straight line.

Step 12

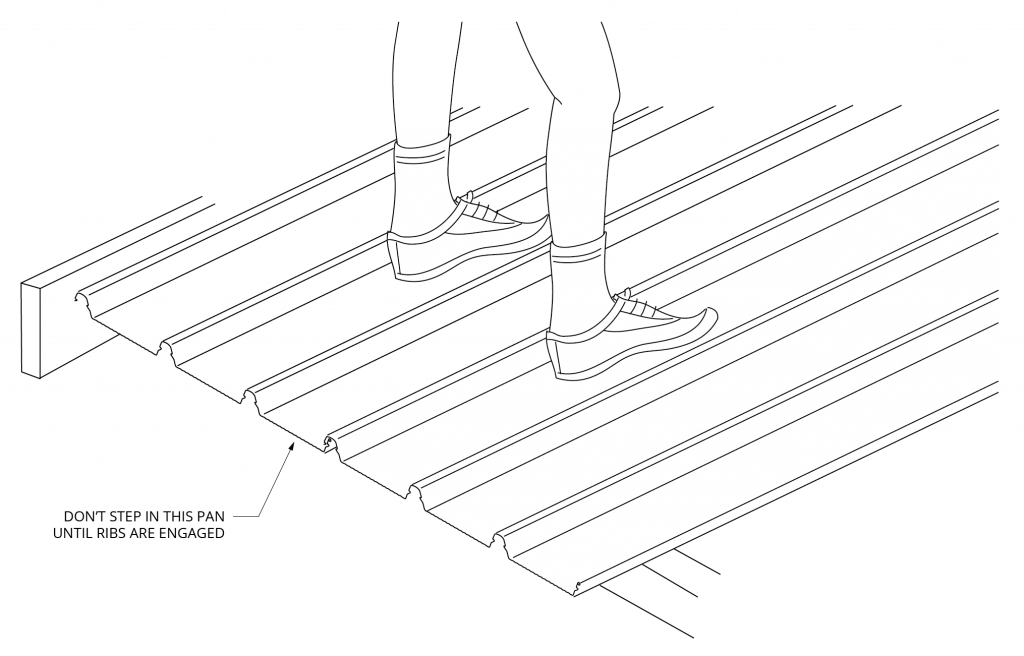

Fully engage the two sheets along the overlapping rib. You can do this by walking along the full length of the sheet with one foot in the centre pan of the previous sheet and the other foot applying vertical pressure to the top of the interlocking ribs at regular intervals. It is important that you don’t walk in the unsupported pan beside the overlap (Figure 5).

Step 13

With long spans, additional care may be required to ensure the overlapping rib adequately engages onto the underlapping leg. Care should be exercised due to the potential instability of the side-lap when it is not adequately engaged (interlocked).

Step 14

Similarly, engage all the clips by applying vertical foot pressure to the top of the other two ribs over each clip.

It is essential that the sheets interlock completely. It is important that your weight is fully on the sheet you are installing.

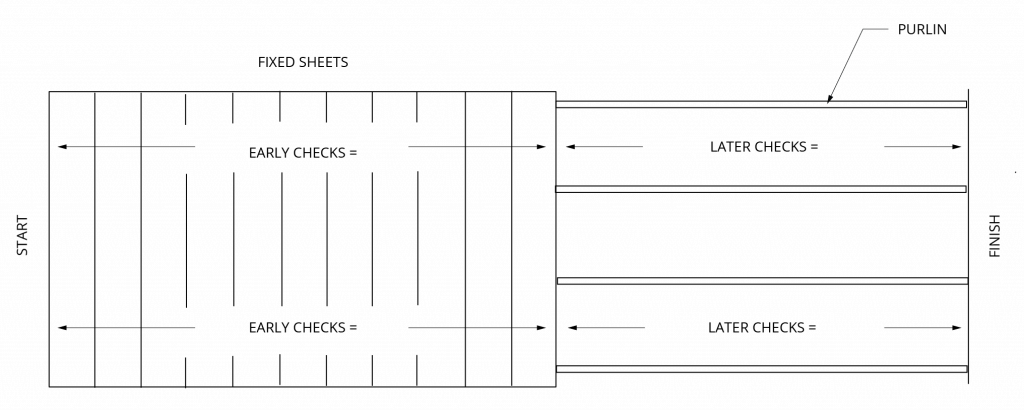

CHECK ALIGNMENT OCCASIONALLY

Occasionally check that the sheets are still parallel with the first sheet, by taking two measurements across the width of the fixed sheeting.

At about half way through the job, perform a similar check but take the measurements from the finishing line to aim for the final sheet to be parallel with the end of the roof. If the measurements are not close enough, lay subsequent sheets very slightly out of parallel to gradually correct the error (Figure 6). Therefore, to allow this to happen, flatten the tabs on the base of subsequent clips—the slot in the clip will allow the clips to be fixed out of standard pitch.

FIX THE LAST SHEET

If the final space is less than the full width of a sheet, you can cut a sheet along its length and shorten the clips as appropriate.

INSTALLING KINGKLIP® 700 WALLS

In walling applications, horizontal pressure will need to be applied locally to the sheets to engage the ribs. Use body pressure (torso, hand or foot) or use a rubber mallet if required. Care should be exercised due to the potential instability of the temporary worker access equipment.

To prevent KingKlip® 700 from sliding downward in the fixing clips, you should pierce-fix through each sheet under the flashing or capping, along the top of the sheets.

KINGKLIP® 700

The new KingKlip® system provides installers with quick and easy end joint/expansion joint solution.

Turning of Roof Sheeting Ends

Refer to section “Flashings, Cappings & Ends of Sheets”.

Designing Without Step Joints

Refer to section "Long Length Roofing Solutions".

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Fielders® King-Lap™ and KingKlip®700

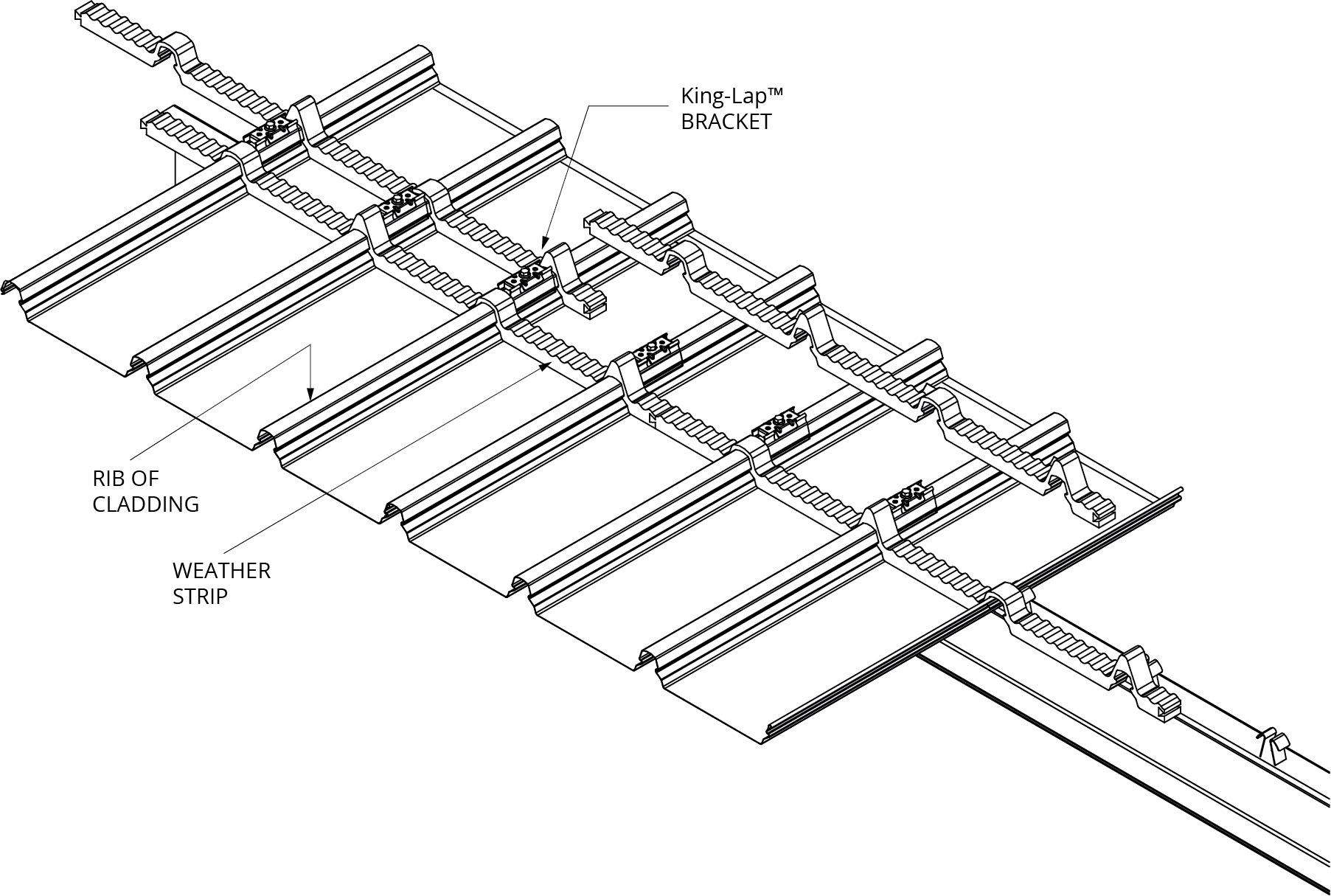

The King-Lap™ system provides a quick and easy end joint/expansion joint solution for KingKlip® 700. The King-Lap™ system comprises an engineered ZINCALUME® steel bracket and shaped foam weather strip. The King-Lap™ bracket replicates the role of a standard KingKlip 700® bracket and is secured to the ribs of the bottom sheet using standard roofing fasteners.

Benefits of King-Lap™

- Low profile system maintains roof aesthetics with clean, long run roof lines for KingKlip® 700 cladding.

- Avoids step joins and purlin complexity to provide a cost effective way to achieve a long-length roofing design, even when using shorter roof sheets.

- Fast and easy to install – minimal change to current KingKlip® 700 installation practice.

- Tested and proven in our NATA-accredited testing facility. If installed correctly, will preserve all existing roofing warranties and capacities.

- Safe and effective weather resistant seal.

- Suitable for cyclonic applications.

- Readily allows for thermal movement of roof sheets.

- As a stand alone solution, compatible with translucent sheeting.

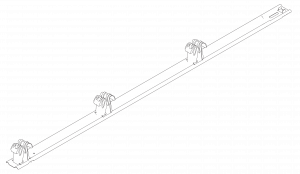

King-Lap™ is comprised of brackets which are fixed to the ribs and two separate weather strips.

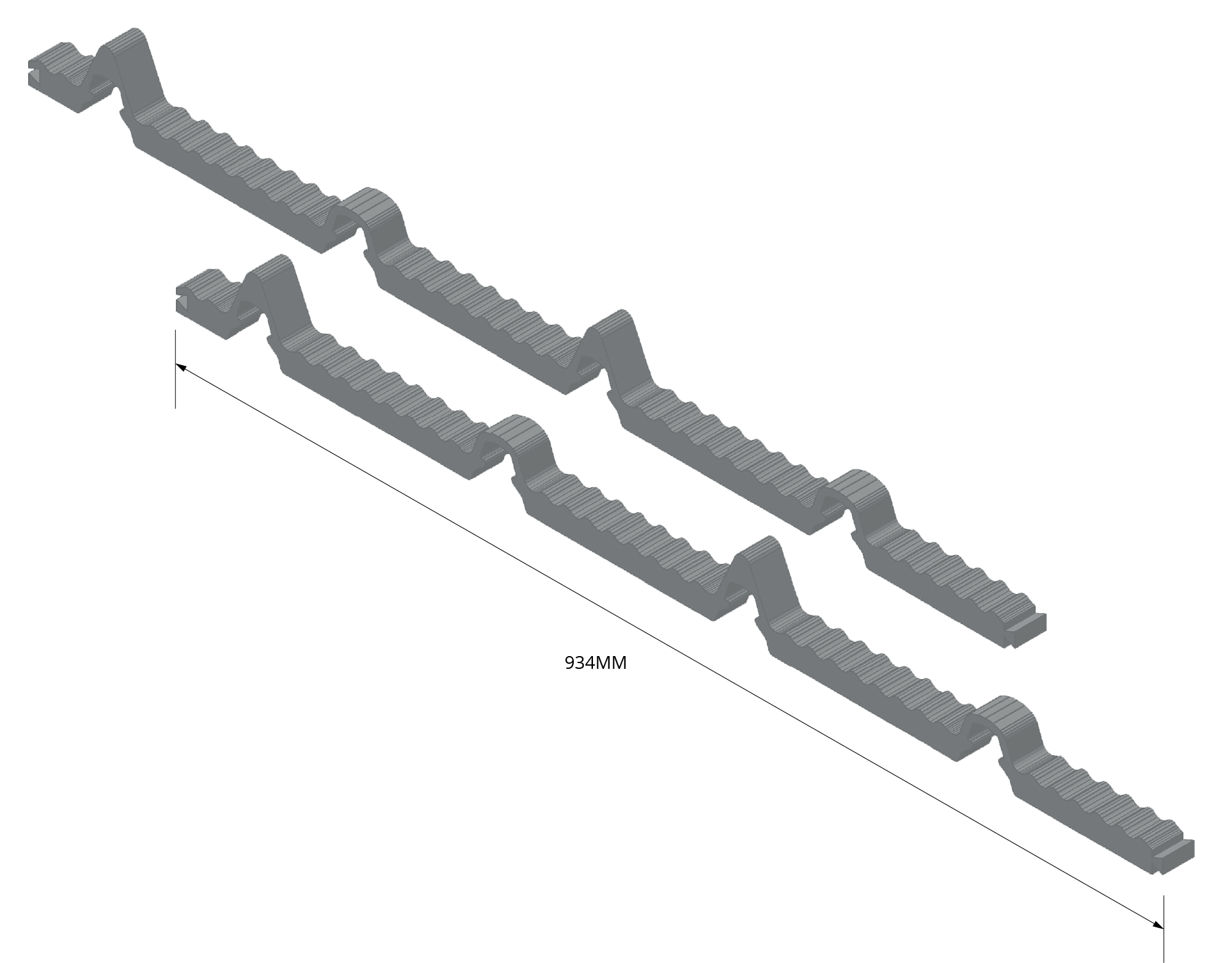

Figure 1

Background on thermal expansion

All metals expand and contract with changes in temperature. Although steel is by far the least affected of all the metals commonly used for roof and wall cladding, the changes in length experienced in very long runs of roofing are significant.

When a King-Lap™ is used, the length of each individual sheet is necessarily shorter, thus reducing the impact of thermal movement.

King-Lap™ is an expansion joint/lap joint hybrid

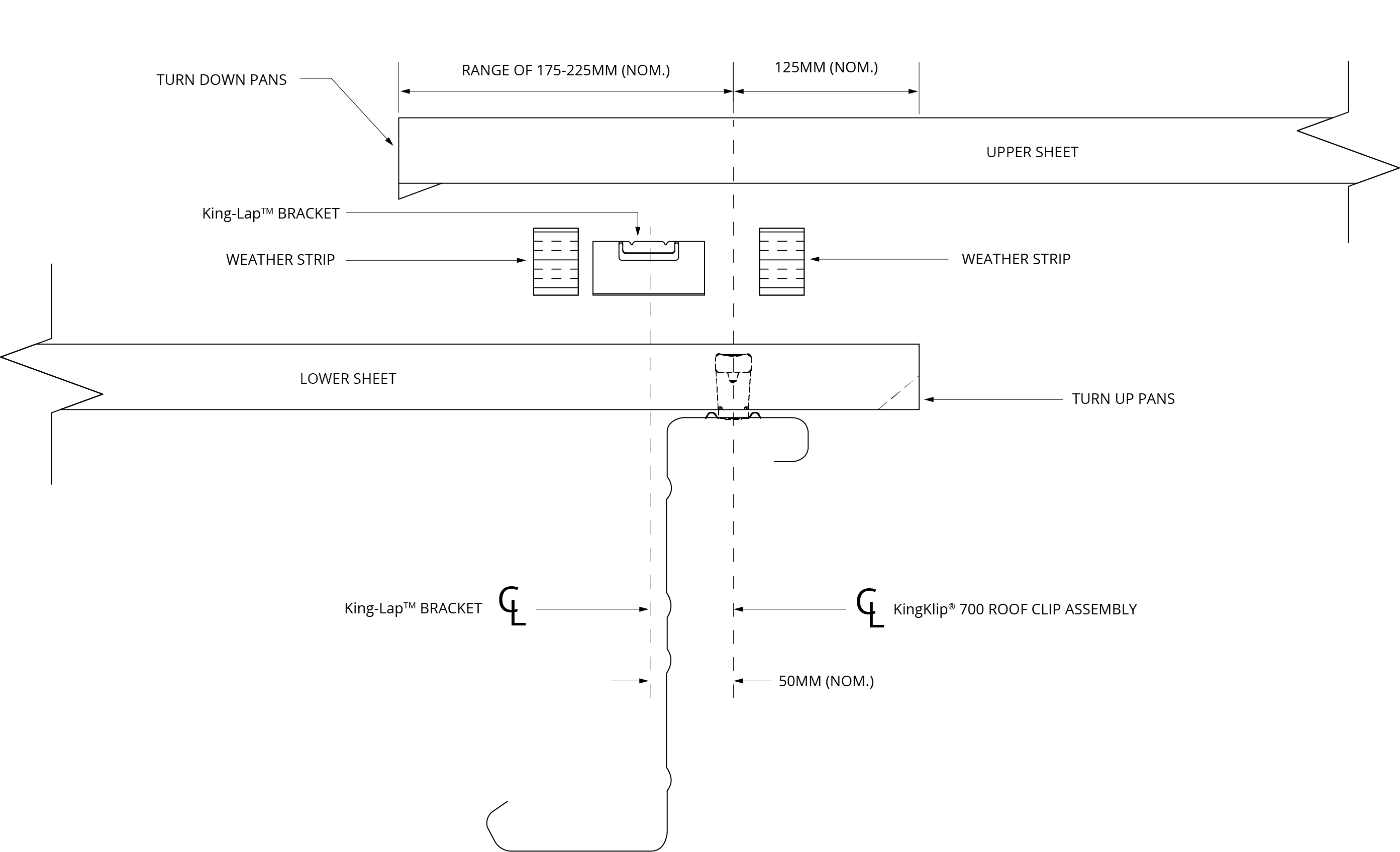

An expansion joint involves overlapping the ends of the upper sheets over the ends of the lower sheets. With King-Lap™, no extra purlin is needed at the joint.

A weather strip provides protection from wind-blown rain and is made from closed cell polyethylene foam. It is used between the upper and lower sheets and laid in pairs, one either side of the King-Lap™ bracket to provide a weather resistant barrier from wind driven rainwater. It also provides air flow to reduce likelihood of condensate build-up.

The King-Lap™ bracket is a pressed metal component that saddles the rib of the KingKlip®700 roofing by engaging the “S” bends of the lower sheet and is clipped into place. The bracket is fixed to the lower sheet by fasteners through the pre-punched holes however this allows the upper sheet to move relative to the bracket due to thermal expansion.

Testing

Made from Australian-made G550 AZ150 ZINCALUME® steel, King-Lap™ is strong. King-Lap™ has been tested for performance in wind uplift and weather-resistance at Fielders® NATA-accredited materials science testing laboratory. This means you can be confident that King-Lap™ will perform to specification when installed according to our design limitations and installation guidelines.

Wind uplift tests were performed to ensure King-Lap™ clips met the performance standards required.

Figure 2

Weather test rig is used to test weather-resistance by blowing simulated wind borne rain.

Figure 3

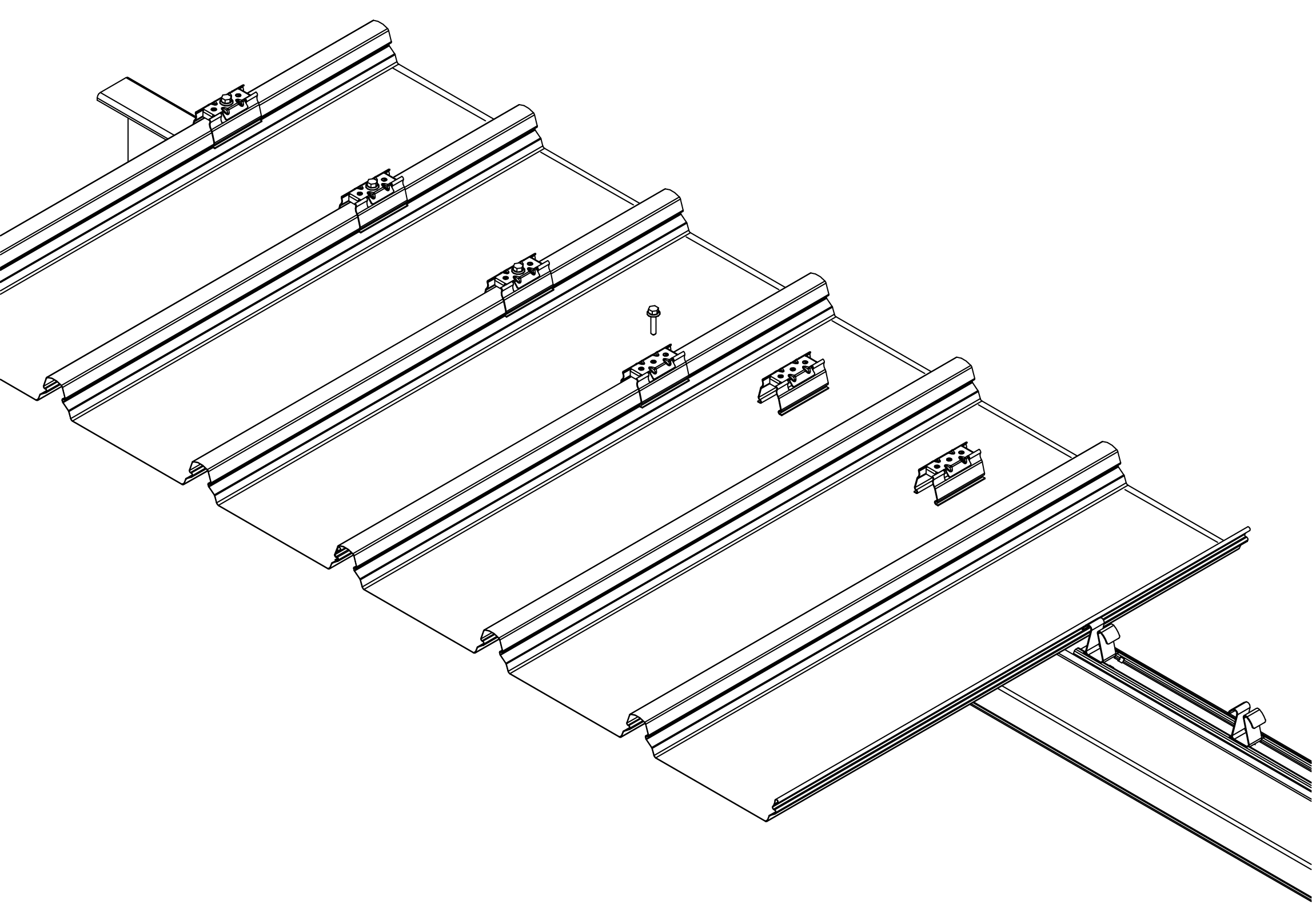

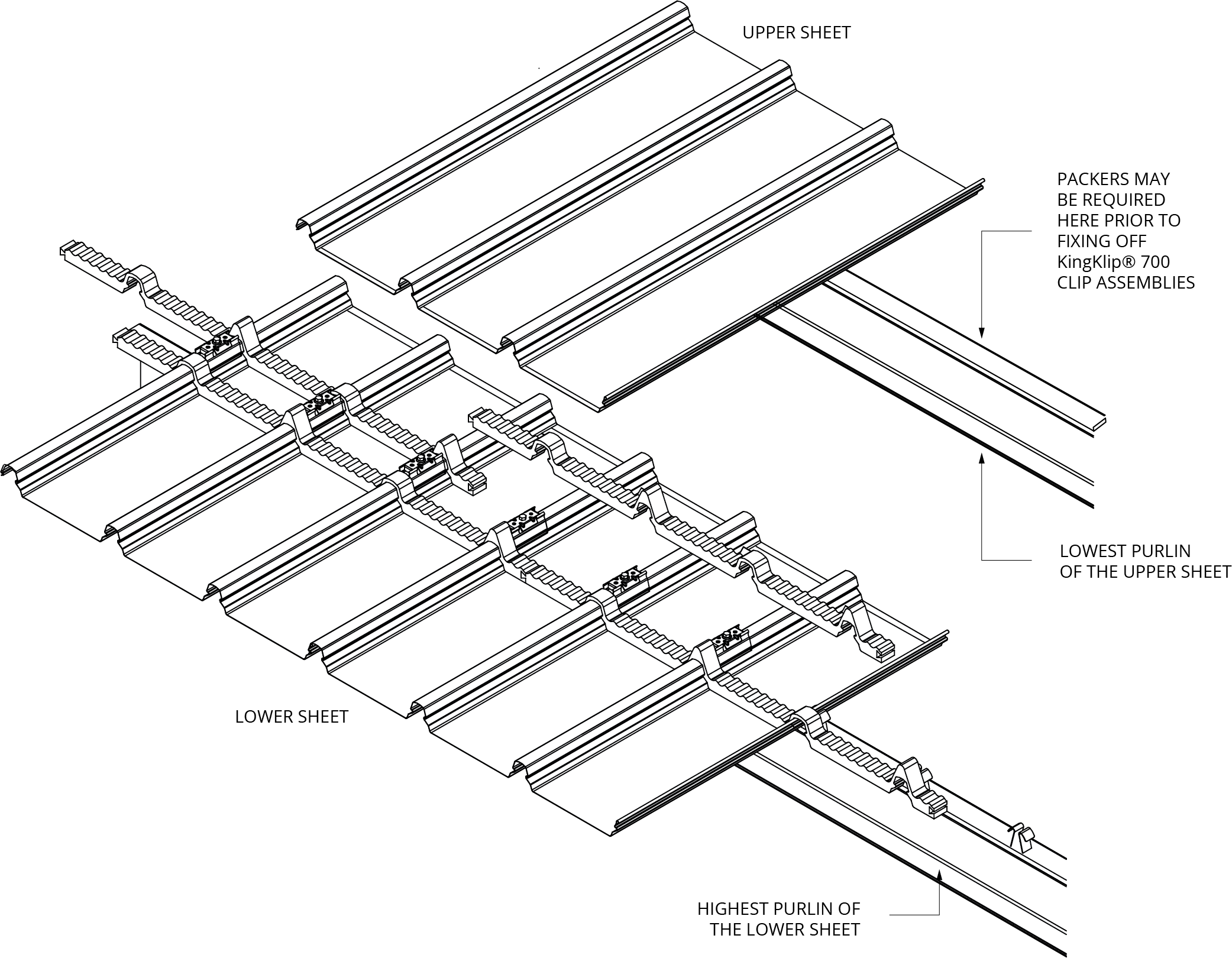

King-Lap™ joint layout and fixing

This will allow normal concealed fastening at the support and thus allowing thermal movement to occur at the King-Lap™. To install the King-Lap™ bracket, locate each King-Lap™ bracket as per Figure 5, then hand press to snap fit each King-Lap™ bracket to the KingKlip®700 (Figure 4a, 4b). For non-cyclonic areas, using a low torque setting on the drill to ensure the cladding is not stripped, secure through the top hole of the King-Lap™ and also through the crest of the lower sheet (Figure 4a). For cyclonic areas, use two fasteners by fixing through the sides of the King-Lap™ bracket into the sides of the rib (Figure 4b).

Weather strips are laid either side of the King-Lap™ brackets and offset (see installation steps).

Figure 4

King-Lap™ Installation

Roof Design Considerations

The roofing sheets are not to exceed the maximum recommended end span either side of the King-Lap™ joint. To ensure drainage, refer to table below.

Drainage

| Purlin Spacing (mm) | Minimum Roof Slope |

| 1750 | 1° |

| 1250 | 1.5° |

| 850 | 2° |

For advice on roof drainage, refer to the Fielders® Roofing & Walling Installation Manual. It may be necessary to employ packers to provide a more gradual change in the slope of the roof.

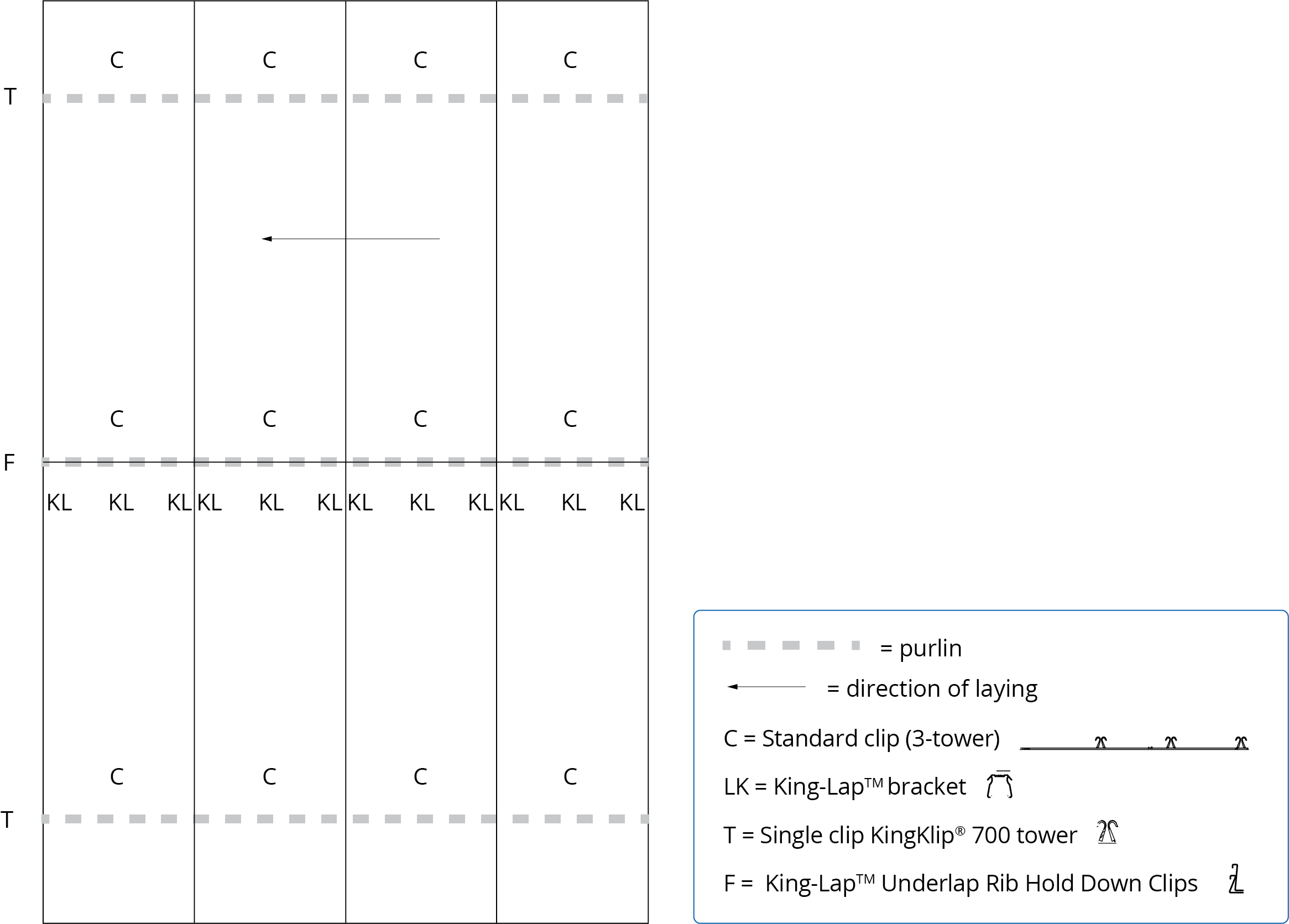

When specifying or ordering, please refer to the layout schematic detailed below.

This layout shows the location and types of clips/brackets required to fit a KingKlip®700 using King-Lap™ end joint.

Figure 6: Layout of clips

King-Lap® assembly components

| King-Lap® assembly components | |

| King-Lap® brackets | 43 per 10m |

| Weather strip | 22 per 10m |

| King-Lap® Underlap Rib Hold Down Clips (F) for each finishing end of the King-Lap® joint | 1 |

Turn-up and Turn-down of KingKlip®700 AT King-Lap™® joint

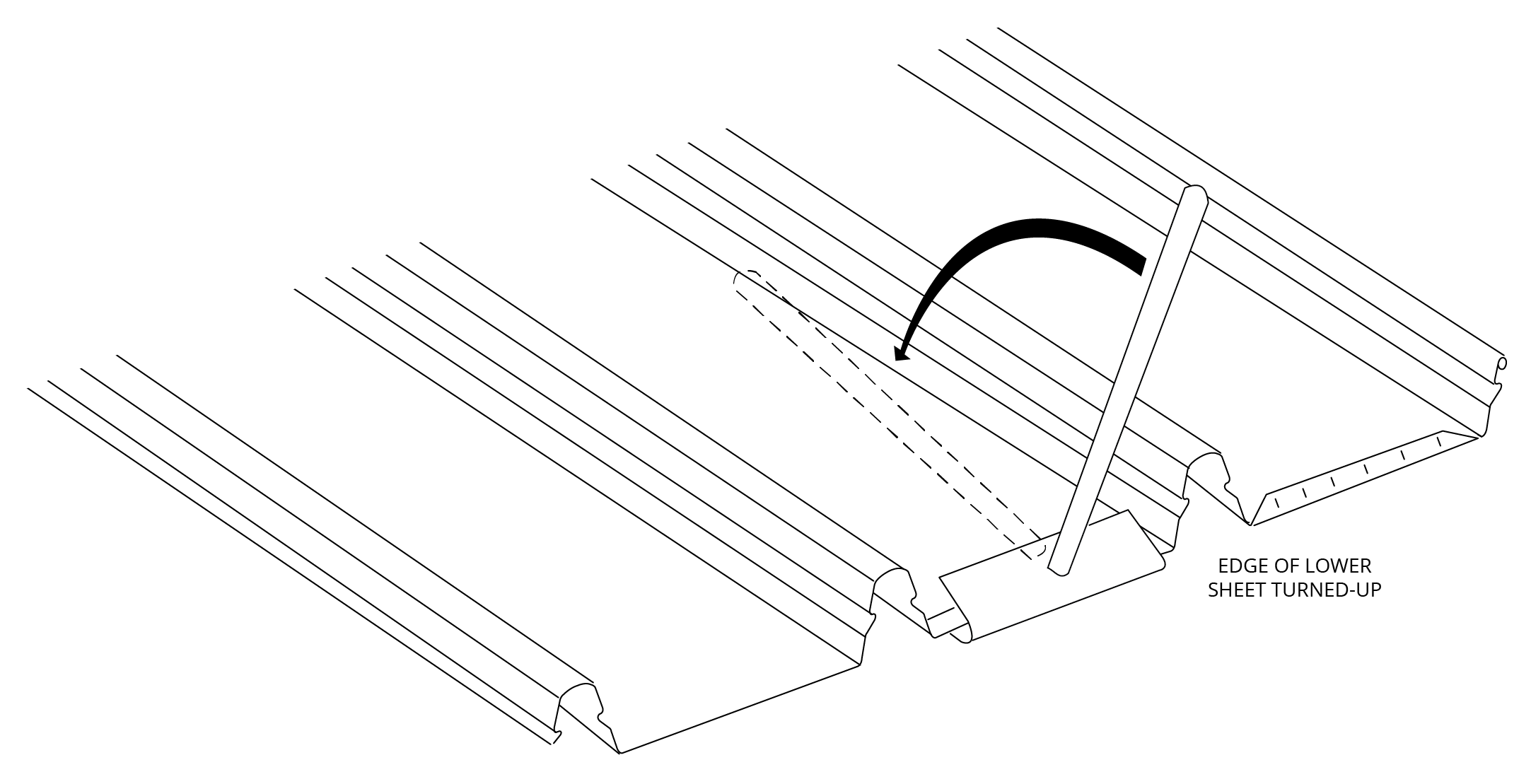

Turning-up

Turn-ups are performed on the upper end of the lower sheets using the turn-down tool. Holding the end of the tool against the end of the sheet, pull the handle until the handle bottoms out onto the pan, being careful not to tear the cladding.

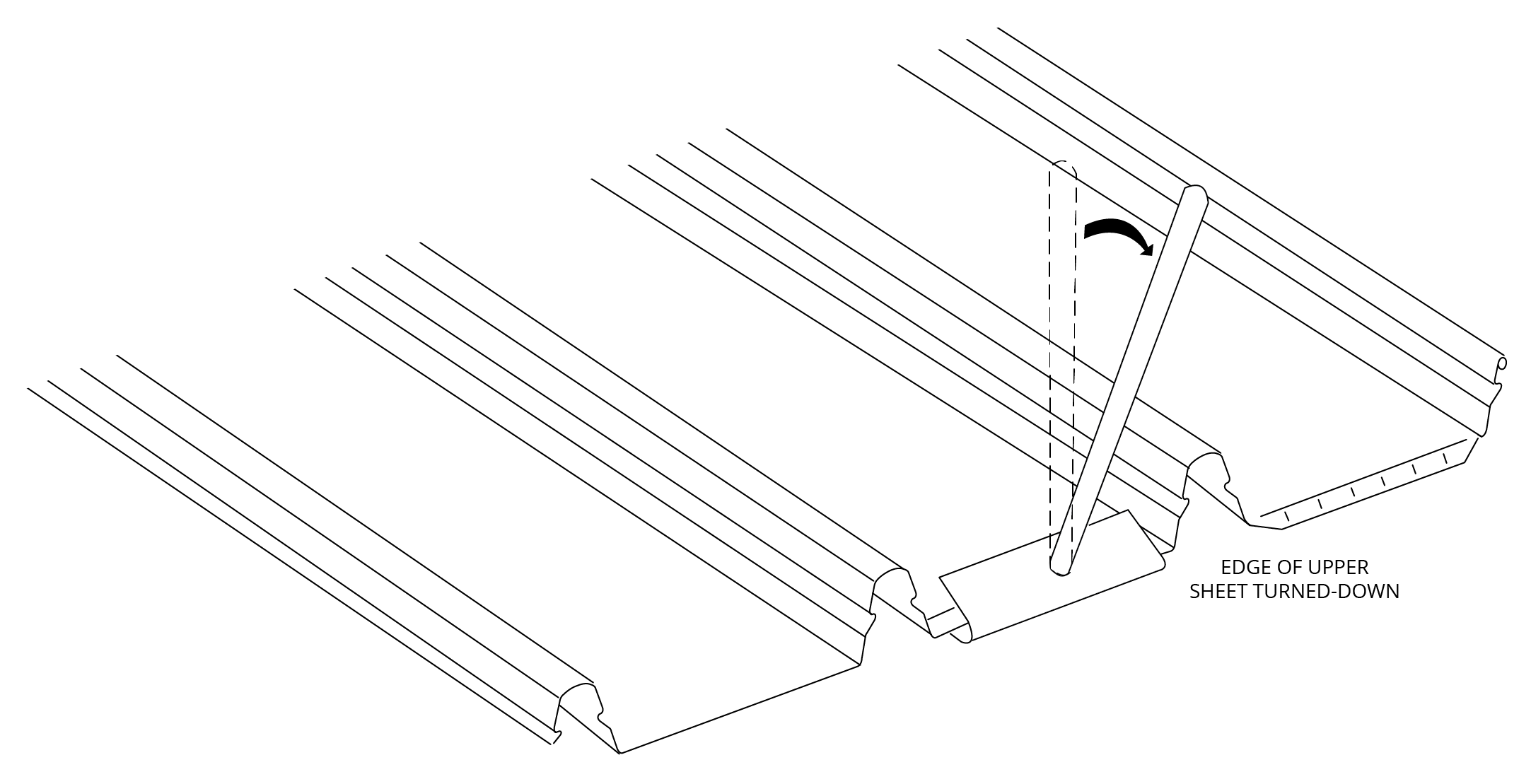

Turning-down

The upper sheet of a King-Lap™ joint requires the lower end of the upper sheet to be lipped prior to laying the sheets.

- Push the turn-down tool over the end of the tray, as far as it will go.

- Hold the tool hard against the end of the tray and pull the handle until the lipped edge bottoms out on the underside of the pan, resulting in a nominal 20 degrees lip (Figure 7.)

Again, be careful not to tear the sheet.

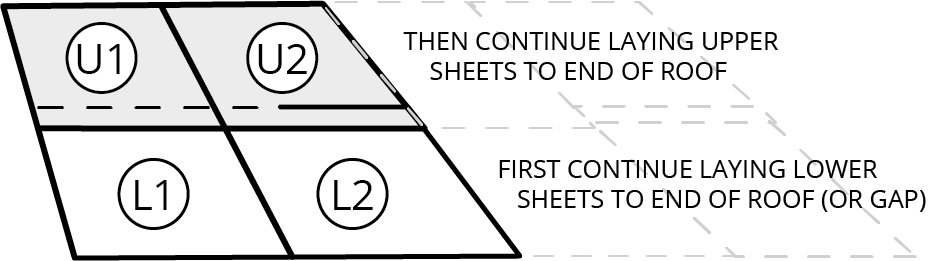

Step 1:

The installation of KingKlip®700 should generally be in accordance to the instructions given in the Fielders® Roofing and Walling Installation Manual.

Install the lower sheets of the KingKlip®700 prior to installing upper sheets as per the above sequence. The number of sheets laid will depend upon the site conditions and installer programme. Packers (10mm thick) may be required on the lowest purlin of the upper sheet for roofs of less than 2° slope and less than 1400mm span. For further information contact your nearest Fielders® Service Centre.

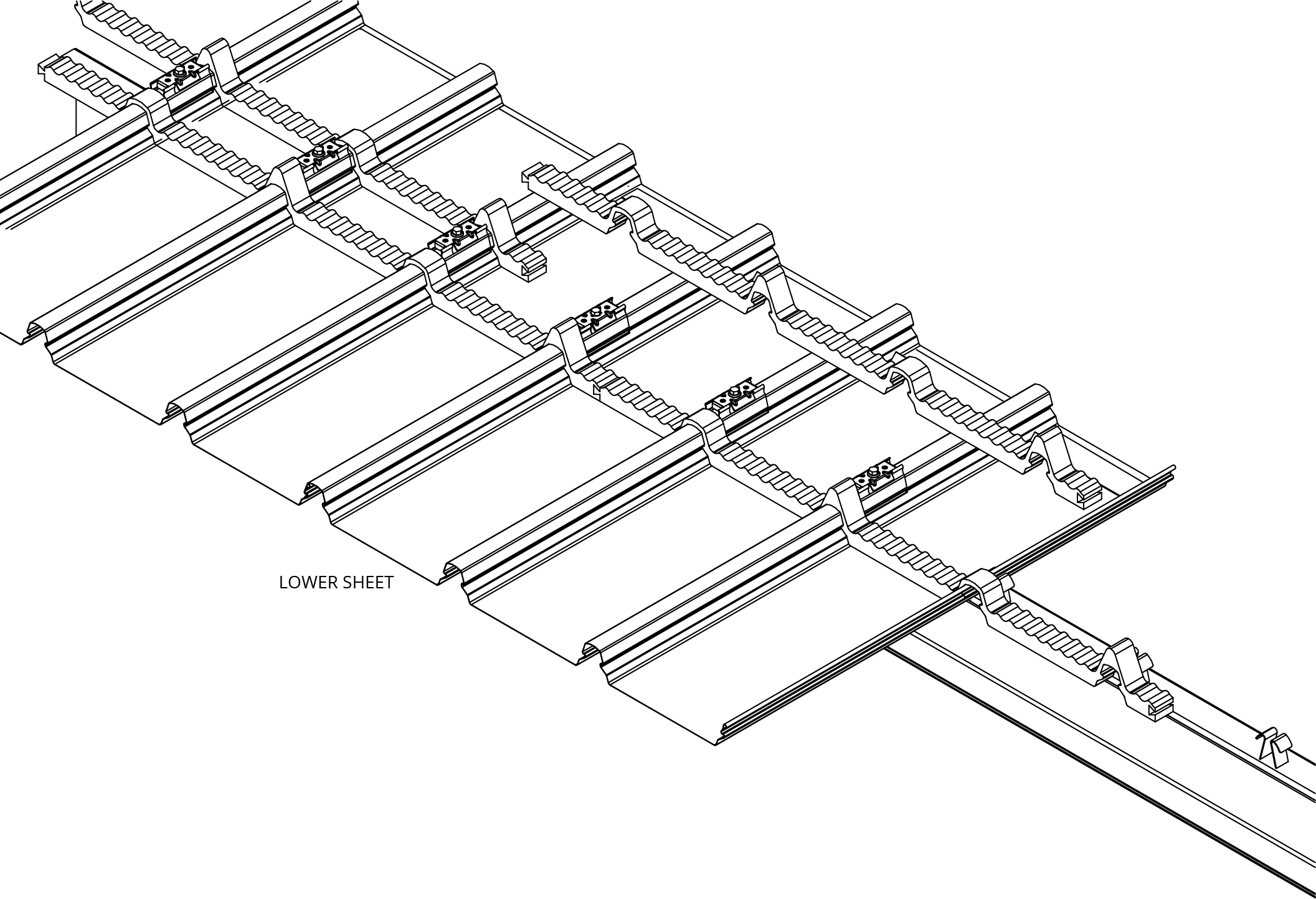

Step 2: Turn-up of pans

The pans on the upper end of the lower sheet are to be turned-up as detailed prior to fitting King-Lap™ brackets.

Figure 10

Step 4: Place weather strips

Interlocking weather strips are installed on top of cladding so they interlock to similar weather strips each side. The weather strips are placed on both sides and adjacent to the brackets.

The join on the weather strip should not be positioned adjacent to the male leg (underlap rib). Furthermore the two rows of weather strips must have the join in alternating pans (i.e. the joins are off-set).

Ensure the weather strips properly nest into the ‘S’ bends of the ribs and this allows for a staggered ventilation path.

Place upper sheet over King-Lap™ end joint.

Figure 12

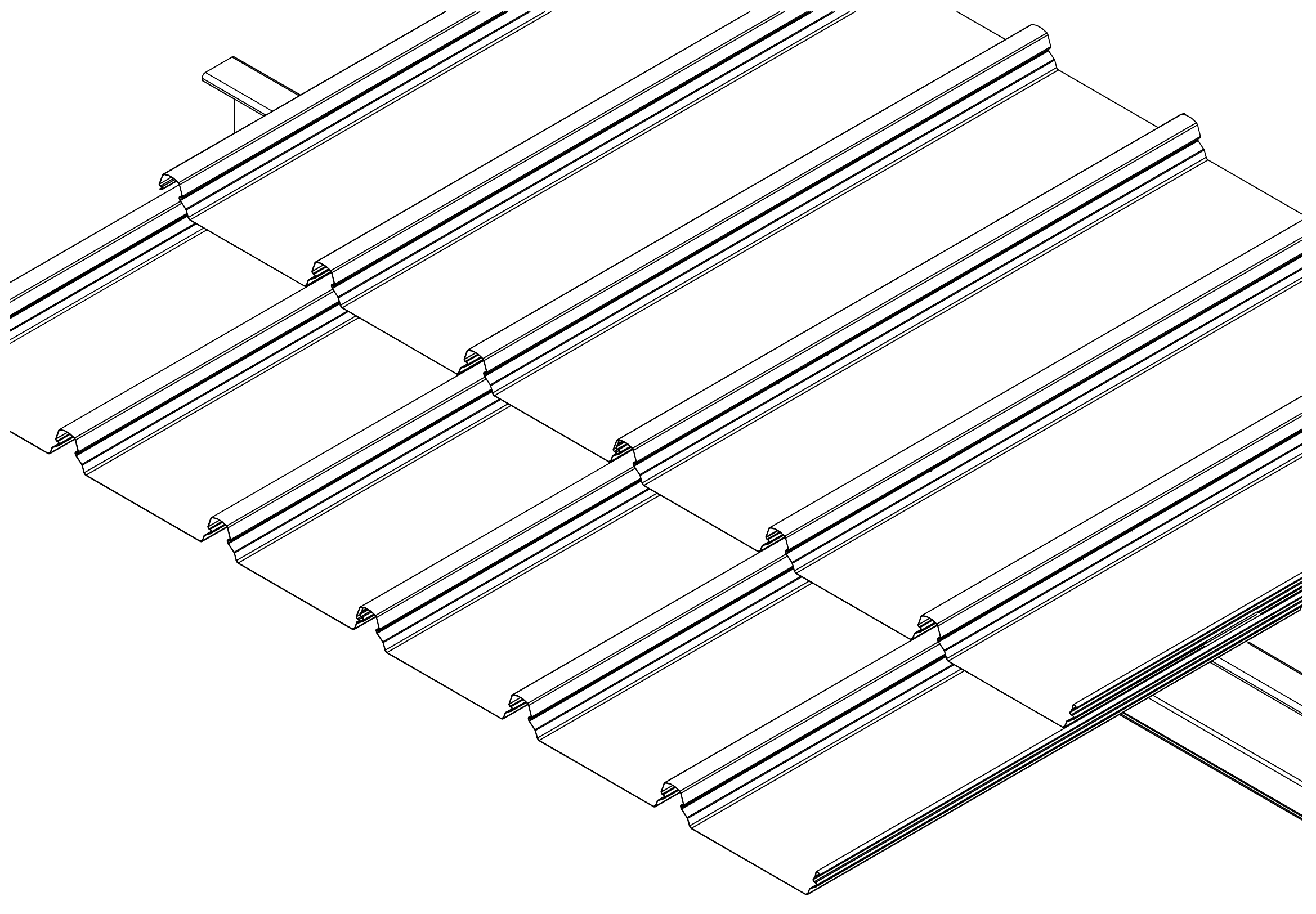

Step 5: Lay upper sheet over King-Lap™

Prepare the upper sheets by turning down the pans at the lower end of the sheet as detailed.

Position the upper sheets, taking care not to dislodge the previously installed weather strips.

While standing on the lower sheet, install the upper sheet onto the King-Lap™ brackets by first engaging the inner ribs and then the female side-lap rib (listen for the “snap” engagement). This engagement is done by foot pressure. Ensure correct engagement of the male leg onto the King-Lap™ bracket.

Install the remainder of the upper sheet onto the standard fixing clips using the standard process.

King-Lap™ Underlap Rib Hold Down Clips (F).

Figure 13

Step 6: Finishing

Continue the above process to the finishing edge/end of the roof. At the finishing edge of the roof, it is necessary to secure the two underlap ribs using Underlap Rib Hold Down Clips (F) screwed into position. The overhanging weather strips can be cut or torn off. It is now ready to receive barge flashing. Avoid walking at the roof edge.

Completed King-Lap™