About Spanform™

Spanform™ is the multi-rib and multi-purpose roofing and walling panel from Fielders®. Offering impressive spanning qualities and optimum durability, Spanform™ provides the flexibility you need to design and build a variety of steel projects. Using innovative design, Spanform™ has higher and squarer ribs to provide its impressive strength. Despite being similar to corrugated steel in appearance, Spanform™ can achieve much more as a steel roofing and walling product. Available in long lasting ZINCALUME® and COLORBOND® steel, suitable as either roofing or walling product.

Material Specifications

| Property | Notes | |||

| Base Metal Thickness (mm) | 0.42 | 0.48 | BMT | |

| Total Coated Thickness (mm) | 0.47* | 0.53* | TCT | |

| Mass / Unit Length | ZINCALUME® | 3.30 | 3.70 | kg/m |

| COLORBOND® | 3.36* | 3.77* | ||

| Mass / Unit Area | ZINCALUME® | 4.71 | 5.29 | kg/m2 |

| COLORBOND® | 4.48* | 5.38* | ||

| 2nd moment of area about principal axis (103 mm4) | Ix | 35 | 40 | |

| Iy | 19840 | 22670 | ||

| Section modulus about principal axis (103 mm3) | Zx | 3 | 3 | |

| Zy | 52 | 59 | ||

| Warping Constant (109 mm6) | Iw | 2 | 2 | |

| Torsion Constant (mm4) | J | 24 | 35 | |

| Minimum Yield Strength | G550 | Base Steel Designation | ||

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME®) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

||

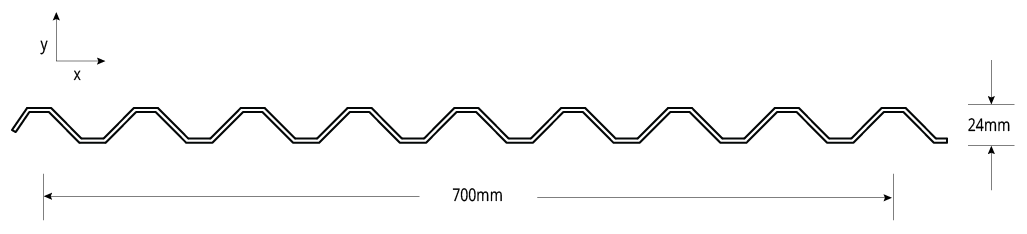

| Coverage (mm) | 700 | |||

| Tolerance | Sheet Length ±7mm Cover Width ±4mm | |||

| Thermal Expansion | 2.9mm average per 5m at 50°C change | |||

Notes:

- Spanform® is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND® ; single-sided material. For other painted steel options please contact a Fielders® representative.

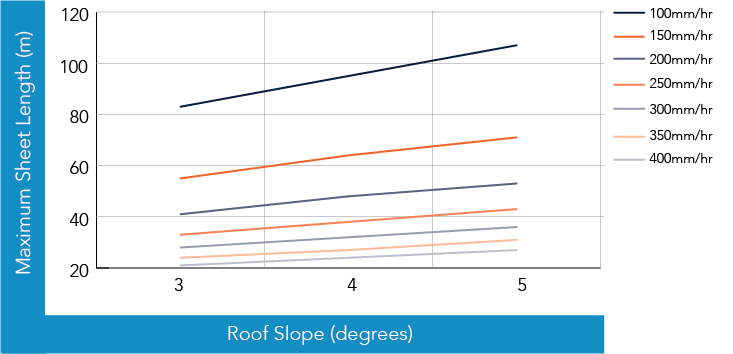

Rainfall Capacity

For further information, please refer to sections "Rainfall Intensity" and "Water Carrying Capacity and Rainwater Run-Off".

Maximum Roof Length (m)

| Roof Slope (degrees) | Rainfall Capacity (mm/hr) | ||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | |

| 3 | 83 | 55 | 41 | 33 | 28 | 24 | 21 |

| 4 | 95 | 64 | 48 | 38 | 32 | 27 | 24 |

| 5 | 107 | 71 | 53 | 43 | 36 | 31 | 27 |

Note:

- Minimum recommended slope is 3°. Sheet lengths greater than 24m are not recommended due to thermal expansion and contraction.

Load Span Tables

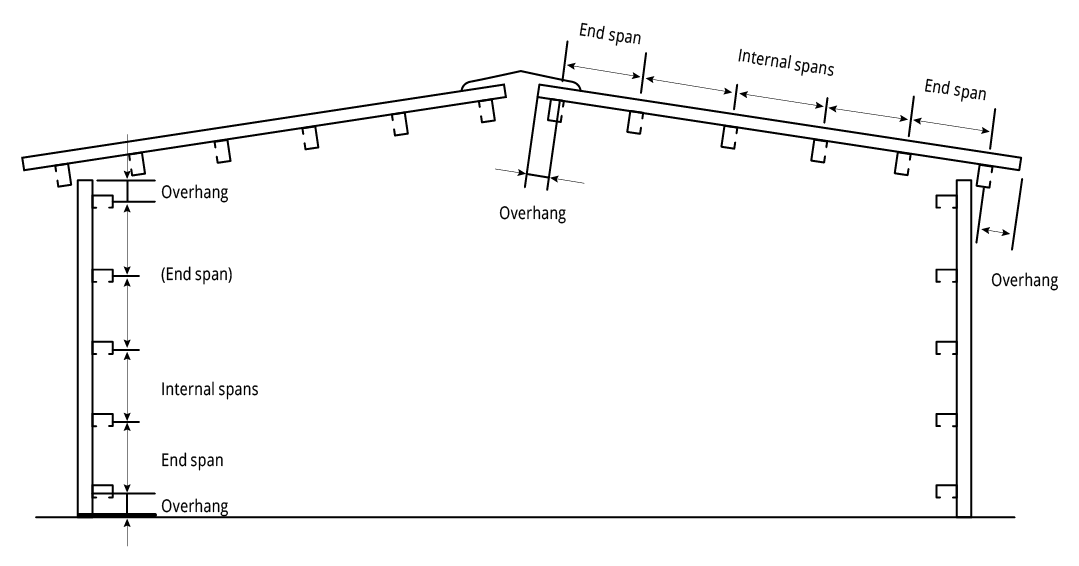

Figure SF NC 002 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Wind Load Capacity: Limit State Design: Crest Fixed: 0.42mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 900 | 2.04 | 8.35 | 2.05 | 5.85 | 1.96 | 6.90 |

| 1200 | 1.64 | 6.85 | 1.82 | 4.40 | 1.81 | 5.80 |

| 1500 | 1.27 | 5.45 | 1.61 | 3.20 | 1.66 | 4.70 |

| 1800 | 0.96 | 4.30 | 1.40 | 2.35 | 1.52 | 3.70 |

| 2100 | 0.72 | 3.50 | 1.20 | 1.85 | 1.37 | 2.85 |

| 2400 | 0.54 | 2.95 | 1.02 | 1.55 | 1.23 | 2.25 |

| 2700 | 0.41 | 2.60 | 0.83 | 1.45 | 1.08 | 1.80 |

| 3000 | 0.30 | 2.30 | 0.65 | 1.40 | 0.93 | 1.60 |

| 3300 | - | - | - | - | 0.79 | 1.50 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Wind Load Capacity: Limit State Design: Crest Fixed: 0.48mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 900 | 2.50 | 9.00 | 3.05 | 7.55 | 2.72 | 9.00 |

| 1200 | 2.08 | 7.55 | 2.58 | 5.65 | 2.40 | 7.05 |

| 1500 | 1.69 | 6.25 | 2.15 | 4.05 | 2.09 | 5.50 |

| 1800 | 1.34 | 5.10 | 1.78 | 3.35 | 1.79 | 4.30 |

| 2100 | 1.04 | 4.25 | 1.47 | 2.85 | 1.53 | 3.40 |

| 2400 | 0.79 | 3.60 | 1.20 | 2.50 | 1.30 | 2.75 |

| 2700 | 0.58 | 3.10 | 0.96 | 2.25 | 1.10 | 2.35 |

| 3000 | 0.38 | 2.70 | 0.75 | 2.10 | 0.95 | 2.10 |

| 3300 | - | - | - | - | 0.82 | 2.00 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Maximum Recommended Roof Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 2 | Terrain Category 3 | ||||

| Single (mm) | End (mm) | Internal (mm) | Single (mm) | End (mm) | Internal (mm) | ||

| A | 0.42 | 1200 | 1350 | 2400 | 1300 | 1800 | 2400 |

| 0.48 | 1600 | 1850 | 3000 | 2000 | 2200 | 3000 | |

| B | 0.42 | 1050 | 1800 | 1150 | 1300 | 1800 | 2400 |

| 0.48 | 1450 | 1700 | 2850 | 1900 | 2200 | 3000 | |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table SF RS 002 - Spanform™ Non-Cyclonic

Note:

- Maximum roofing spans comply with both strength and serviceability wind pressure requirements.

- Spans shown in italics are limited by foot traffic requirements.

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 2 | Terrain Category 3 | ||||

| Single (mm) | End (mm) | Internal (mm) | Single (mm) | End (mm) | Internal (mm) | ||

| A | 0.42 | 1500 | 1900 | 3500 | 1900 | 2600 | 3000* |

| 0.48 | 1800 | 2300 | 3550 | 2200 | 2850 | 3000* | |

| B | 0.42 | 1400 | 1700 | 2950 | 1800 | 2200 | 3000* |

| 0.48 | 1650 | 2100 | 3350 | 2100 | 2700 | 3000* | |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table SF RS 001 - Spanform™ Non-Cyclonic

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

- * Spans in excess of 3000mm may be available subject to enquiry. Wall applications or long spans require particular attention to installation practice.

Pierce Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought. Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Notes:

1. All fasteners used externally should be fitted with an EPDM seal (washer). Do not use punches to form fastener holes.

Fastener Spacings - Non-Cyclonic

Pierce Fixing Table

| Fixing Supports | Crest Fixing | Valley Fixing | Side Lap Fixing |

| Steel 1.0 to 3.5mm | 12g-14x45mm Hex Head Auto Tek Screws with HiGrip and seal | 10g-16x16mm Hex Head Tek Screws with seal | 10g-16x16mm Hex Head Tek Screws with seal |

| Timber Hardwood | M6-11x65mm Hex Head RoofZip Screws with HiGrip and seal | M6-11x25mm Hex Head RoofZip Screws with seal | |

| Timber Softwood | M6-11x65mm Hex Head RoofZip Screws with HiGrip and seal | M6-11x25mm Hex Head RoofZip Screws with seal | |

| Metal Battens (0.55 to 1.0mm) | M6-11x50mm Hex Head RoofZip Screws with HiGrip and Seal | 15g-15x25mm Hex Head Tek Screws with seal |

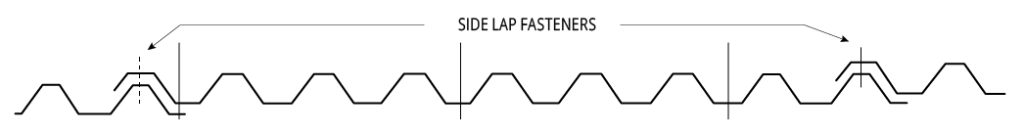

Side Lap Fixing

Side lap fasteners may be necessary at mid spans for purlin spacings over 900mm and girt spacings over 1200mm to hold the sheet laps firmly in place and maintain a weatherproof joint. Use 10g-12x20mm Needle point hexagon head self-drilling stitching screws.

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thickness up to 50mm are installed the screws detailed in Table SF PF NC 001 may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed in to. For timber the screw must penetrate the timber as much as the screws detailed in Table SF PF NC 001 do without insulation.

For insulation thicknesses greater than 50mm Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising any bulging in the profile caused by the insulation.

Spanform™ Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

Turning of Roof Sheeting Ends

Refer to section “Flashings, Cappings & Ends of sheets”.

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving

For details regarding spring and crank curving of SpanformTM sheets, please see section “Curving of Steel Decks”.

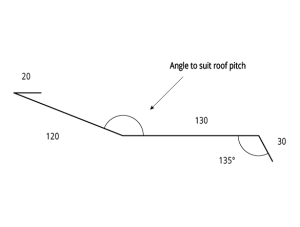

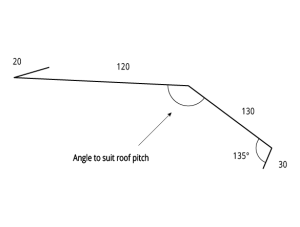

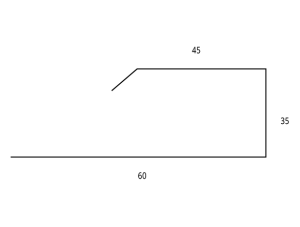

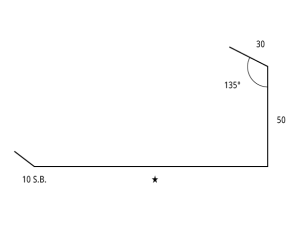

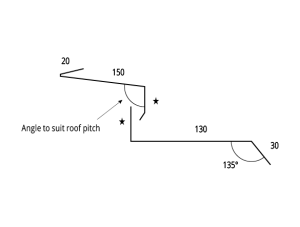

Spanform™ Flashings & Details

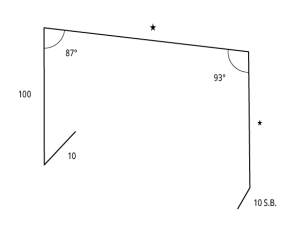

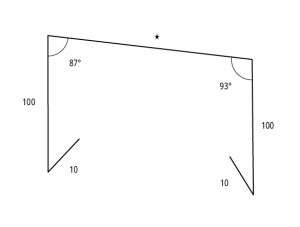

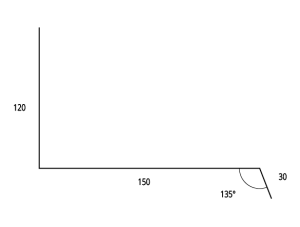

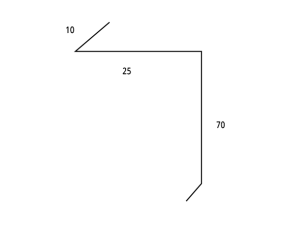

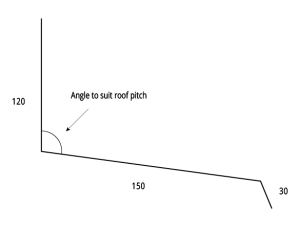

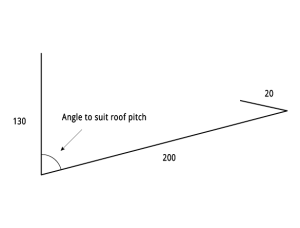

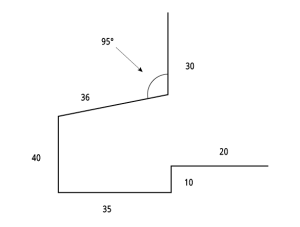

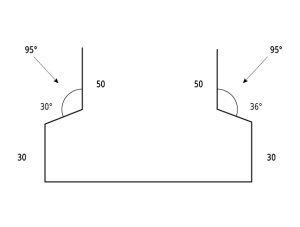

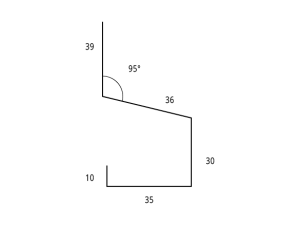

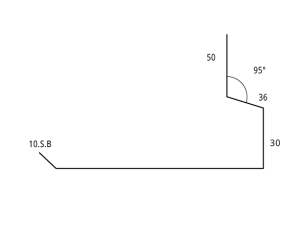

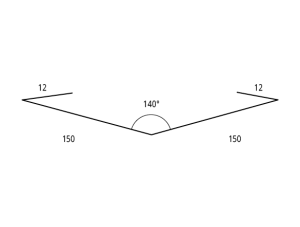

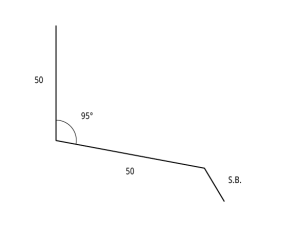

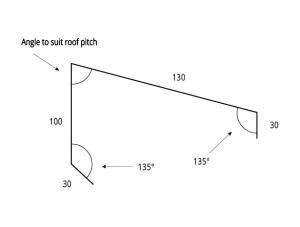

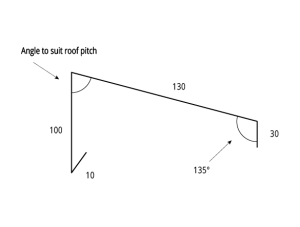

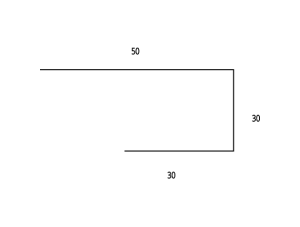

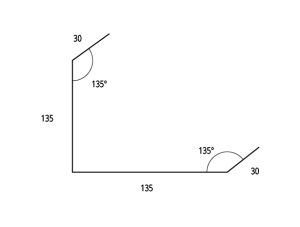

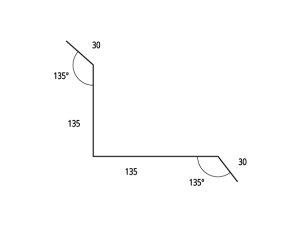

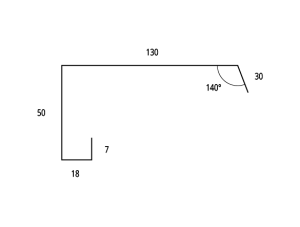

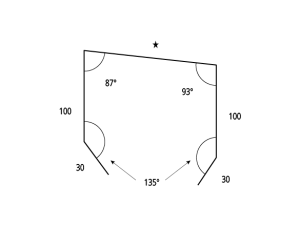

Table SP FD NC 001

Notes:

1. * denotes size to be determined by application. All sizes are in mm and should be used as a guide only. They should be measured on-site to determine actual size.

2. S.B. denotes ‘Slight Break’.

3. Also refer to “Typical Roofing Details”.