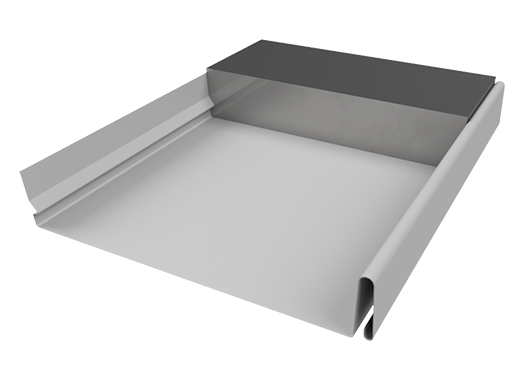

About Cadence®

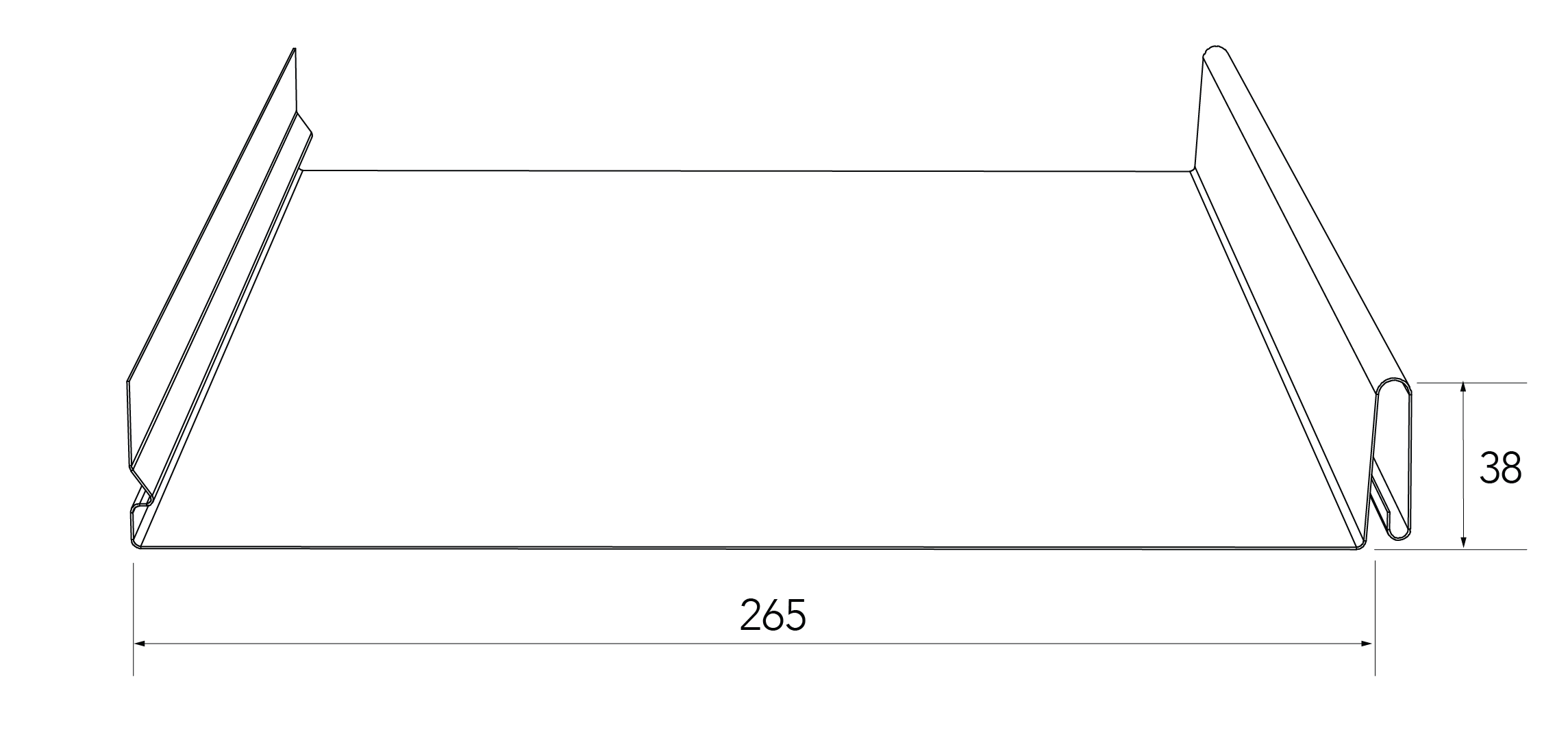

With its elegant flat pans and ease of installation, Fielders Cadence® offers all of the aesthetic benefits of Fielders Prominence™ with additional structural capacities due to the clever concealed fix bracket fixings. These brackets enhance the profile's ability to deal with thermal expansion and contraction. Fielders Cadence® is available in a 265mm and a 465mm wide panel.

As with all the profiles in the Fielders Finesse® range, Fielders Cadence® is available in any COLORBOND® steel colour you choose and looks particularly striking in a Metallic COLORBOND® steel. Cadence® is also available in 0.75mm steel and 0.9mm aluminium (subject to minimum order quantities). Contact your local Fielders representative for availability and further information.

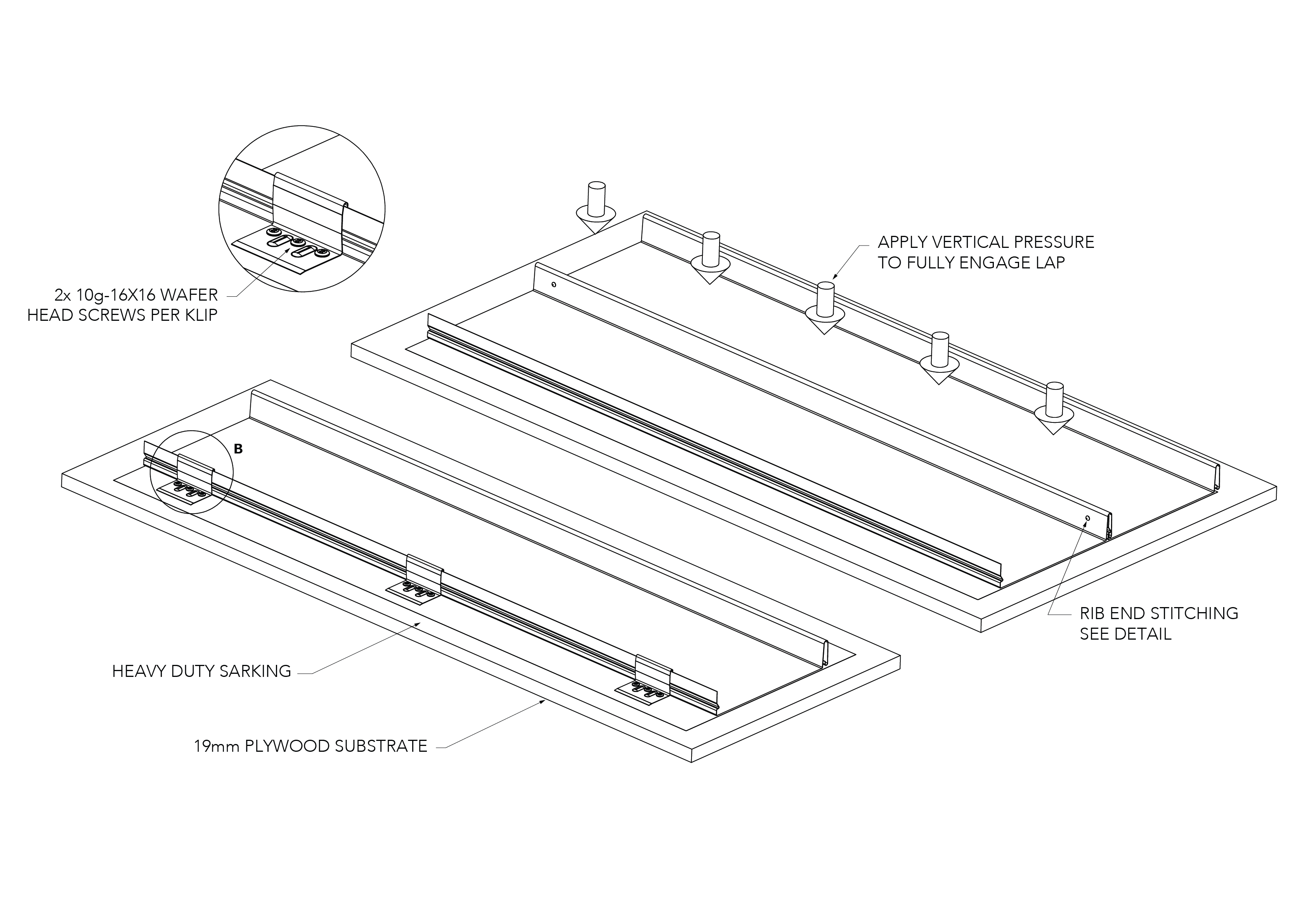

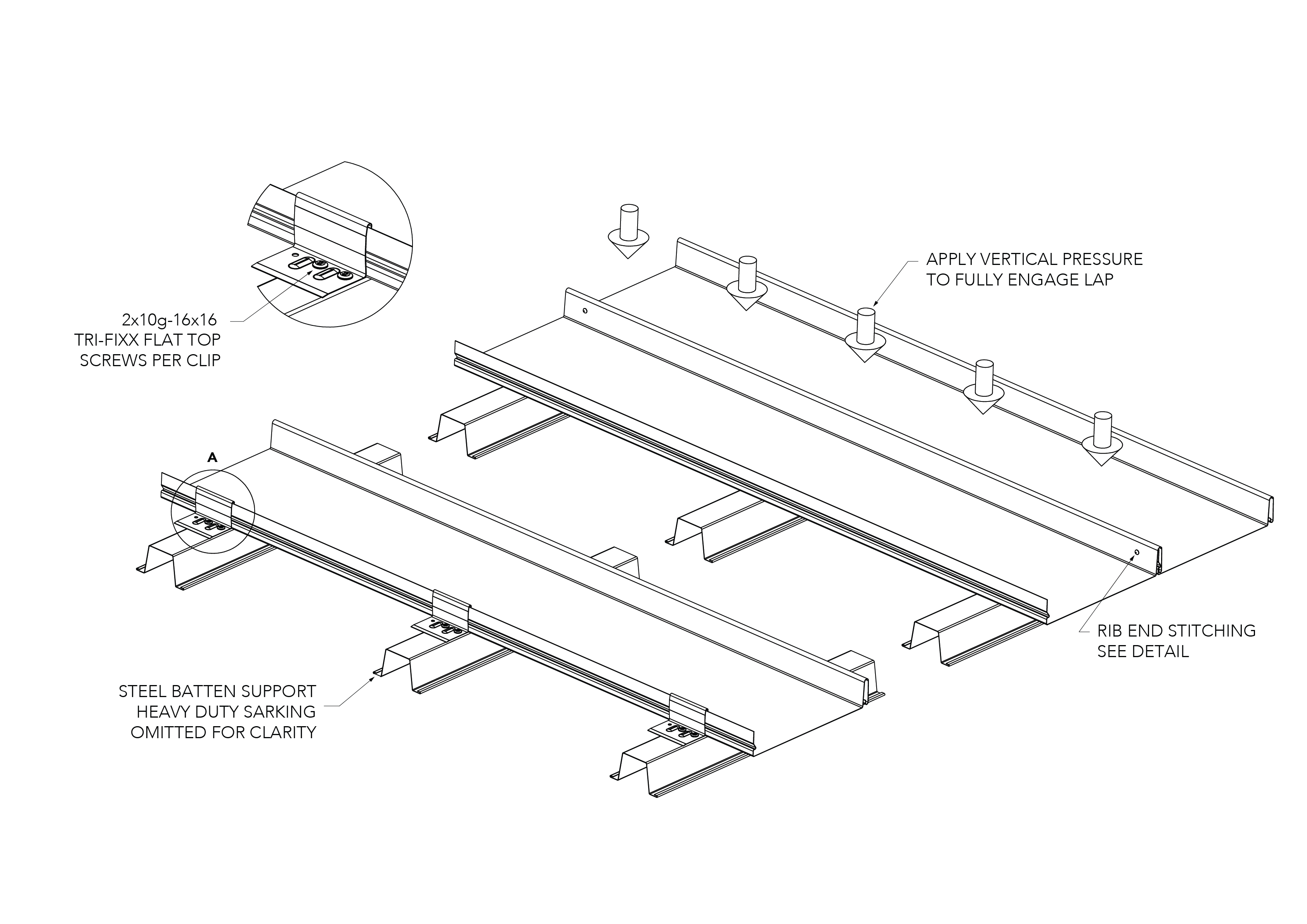

Fielders Cadence® is suitable for installation on traditional supporting substrates such as plywood and fibre cement panels, and now with comprehensive testing, can be offered on cost effective steel battens.

Material Specifications

| Property | 265mm Pan Width | 465mm Pan Width | Notes | |||||

| Base Metal Thickness (mm) | 0.55 | 0.70 | 0.75 | 0.55 | 0.70 | 0.75 | BMT | |

| Total Coated Thickness (mm) | 0.60* | 0.75* | 0.80* | 0.60* | 0.75* | 0.80* | TCT | |

| Mass / Unit Length | ZINCALUME® steel | 1.83 | 2.25 | 2.41 | 2.67 | N/A | 3.61 | kg/m |

| COLORBOND® steel | 1.96* | 2.29 | 2.44* | 2.73* | N/A | 3.68* | ||

| Mass / Unit Area | ZINCALUME® steel | 6.91 | 8.50 | 9.09 | 5.75 | N/A | 7.77 | kg/m2 |

| COLORBOND® steel | 7.02* | 8.65* | 9.21* | 5.88* | N/A | 7.90* | ||

| Coverage | 265 | 465 | mm | |||||

| Minimum Yield Strength | G300 | 300 MPA | ||||||

| Coating Class | AM100 - COLORBOND® steel AM100 - COLORBOND® Metallic steel AM125 - ZINCALUME® steel AM150 - COLORBOND® Ultra steel | Minimum Coating g/m2 of Zinc - Aluminium |

||||||

| Tolerance | Sheet length ±3mm Cover width ±2mm | |||||||

| Thermal Expansion | 2.9mm average per 5.0 metre @ 50˚C change | |||||||

Notes:

- The COLORBOND®; steel and ZINCALUME® steel material is in accordance to AS 1397, AS 1365 and AS 2728.

- Installation of the cladding should also be in accordance to AS 1562.1 and HB 39.

- *is based on Standard COLORBOND®; steel single-sided material. For other painted steel options please contact a Fielders® representative.

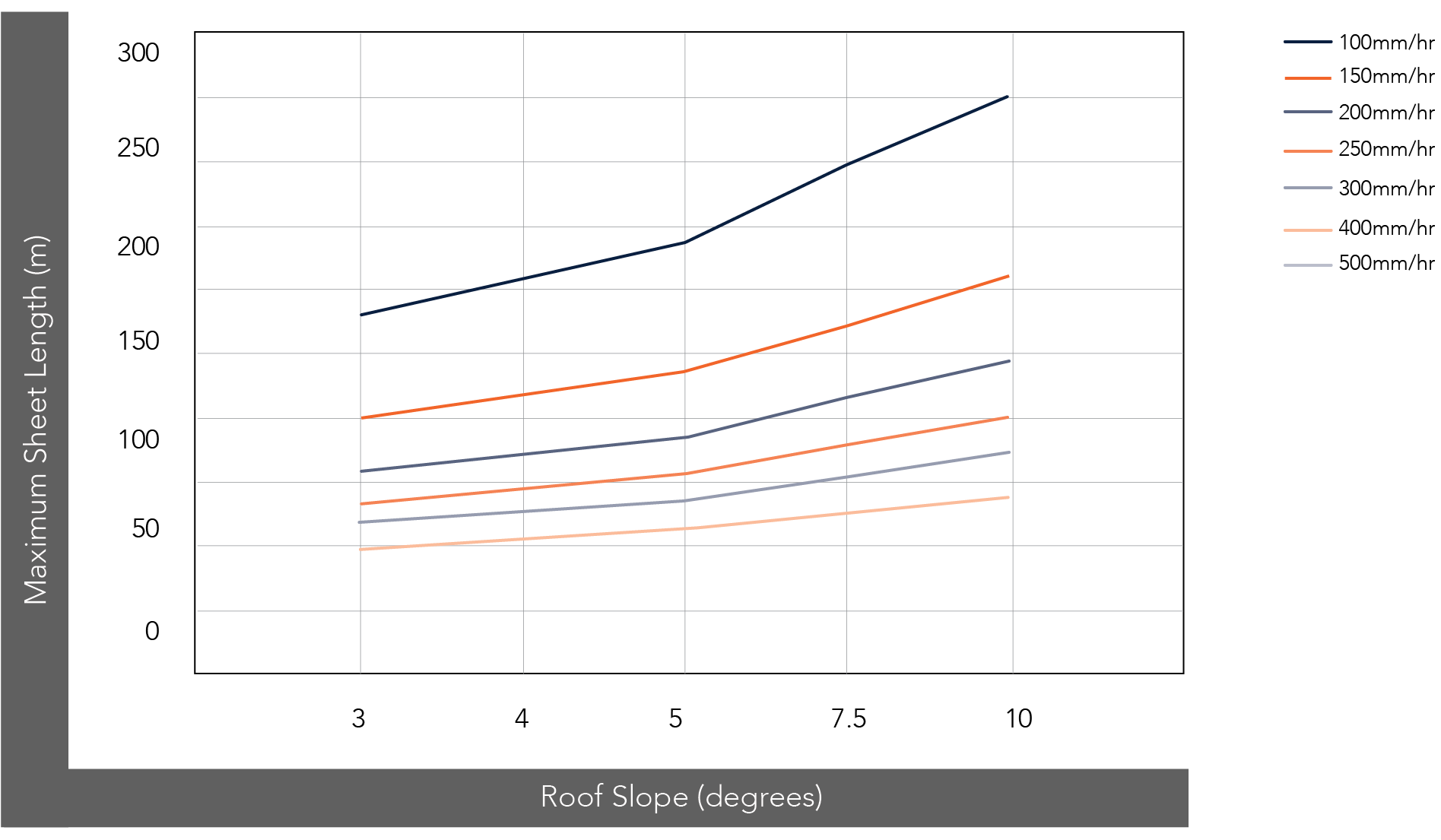

Maximum Roof Length (m) 265 Non-Cyclonic

| Roof Slope (degrees) | Rainfall Capacity (mm/hr) | ||||||

| 100 | 150 | 200 | 250 | 300 | 400 | 500 | |

| 3 | 160 | 107 | 80 | 64 | 53 | 40 | 32 |

| 4 | 180 | 120 | 90 | 72 | 60 | 45 | 36 |

| 5 | 199 | 133 | 100 | 80 | 66 | 50 | 40 |

| 7.5 | 238 | 158 | 199 | 95 | 79 | 59 | 48 |

| 10 | 273 | 182 | 137 | 109 | 91 | 68 | 55 |

Note:

- Minimum recommended slope is 3°. Sheet lengths greater than 15m are not recommended due to thermal expansion and contraction.

Wind Loading Design Parameters

Wind Pressure Capacity: 0.55mm BMT - CADENCE®

| Plywood | Steel Batten | ||||

| Cover Width (mm) | Serv. (kPa) | Strength (kPa) | Spacing (mm) | Serv. (kPa) | Strength (kPa) |

| 265 | 1.00 | 4.5 | 600 | 1.00 | 4.08 |

| 900 | 1.00 | 3.00 | |||

| 465* | 0.30 | 2.5 | 450 | 0.30 | 2.50 |

Note:

- *465mm wide CADENCE®; only recommended for walling applications.

- Serv. denotes serviceability

- Plywood capacities based on maximum support spacing of 600mm & maximum fastener spacing of 450mm (as per Figure PR ID NC 001). Capacities are based on 19mm F11 Structural CD Grade plywood for roofing applications and 15mm F11 Structural CD Grade Plywood for walling applications. In both roofing and walling applications on plywood substrates, CADENCE® should be fastened to the building subframe in accordance with plywood manufacturers recommendations for flooring ply. Screws shall comply with AS 3566 Class 3 as a minimum.

- Steel batten capacities based on maximum batten span of 1200mm and batten base metal thickness of 0.55mm.

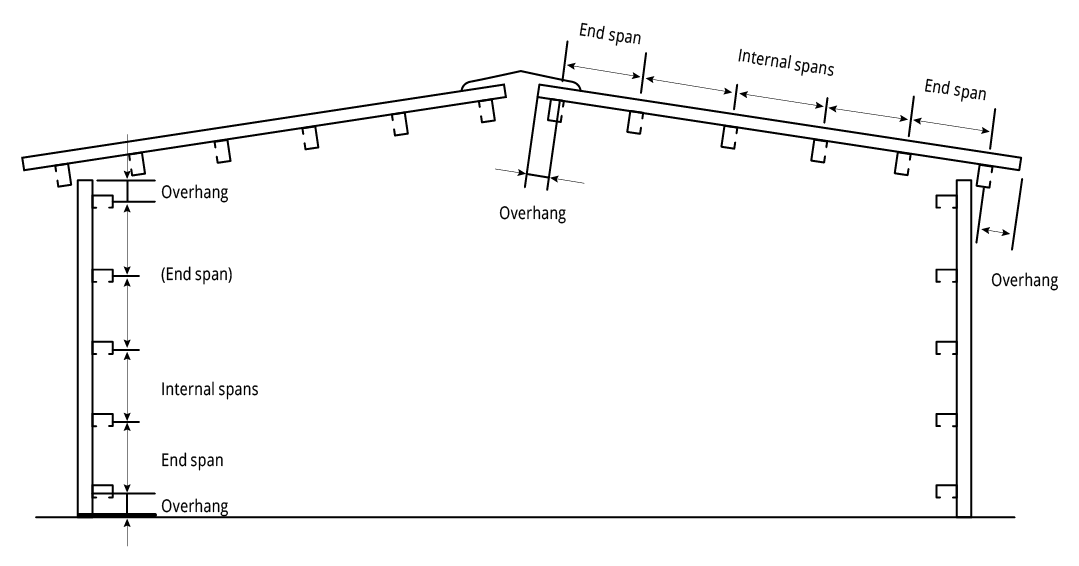

Figure CD NC 001 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Non-Cyclonic Load Span Tables

The design pressures, allowable spans and design data for CADENCE™ have been determined from tests carried out in accordance with on the following Australian Standards:

- AS 1170.2:2011 Structural design actions Part 2: Wind actions

- AS 1562.1-2018 Design and installation of sheet roof and wall cladding Part 1: Metal

- AS 4040.0-1992 Methods of testing sheet roof and wall cladding Part 0: Introduction, list of methods and general requirements

- AS 4040.1-1992 Methods of testing sheet roof and wall cladding Method 1: Resistance concentrated loads

- AS4040.2-1992 Methods of testing sheet roof and wall cladding Method 2: Resistance to wind pressures for non-cyclone regions

- AS4040.3-1992 Methods of testing sheet roof and wall cladding Method 3: Resistance to wind pressures for cyclone regions

- AS4055:2012 Wind Loads for Housing

- SA HB 39: 2015 Handbook - Installation code for metal roof and wall cladding National Construction Code of Australia

Maximum Recommended Roof Cladding Span

| Cover (mm) | Base Metal Thickness (mm) | Single (mm) | End (mm) | Internal (mm) |

| 0.55 | 600 | 900 | 900 | |

| 265 | 0.70 | 700 | 1000 | 1000 |

| 0.75 | 700 | 1000 | 1000 |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficients:

Cp,e = -0.65 (walling)

Cp,e = -0.9 (roofing)

Internal Pressure Coefficient:

Cp,i = 0.2

Local Pressure Factors:

Kl = 2.0 (end & single spans)

Kl = 1.0 (internal spans)

Table CD RS NC 001 - CADENCE® Non-Cyclonic

Notes:

- 465mm wide CADENCE® is available for roofing applications when used in conjunction with 19mm F11 plywood and fixed at 450mm c/c max.

- Max unstiffened overhang is 50mm for all gauges.

Maximum Recommended Wall Cladding Span

| Cover (mm) | Base Metal Thickness (mm) | Single (mm) | End (mm) | Internal (mm) |

| 265 | 0.55 | 900 | 900 | 1200 |

| 0.70 | 1000 | 1000 | 1300 | |

| 0.75 | 1000 | 1000 | 1300 | |

| 465 | 0.55 | 450 | 450 | 450 |

| 0.70 | N/A | |||

| 0.75 | 550 | 550 | 550 | |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficients:

Cp,e = -0.65 (walling)

Cp,e = -0.9 (roofing)

Internal Pressure Coefficient:

Cp,i = 0.2

Local Pressure Factors:

Kl = 2.0 (end & single spans)

Kl = 1.0 (internal spans)

Table CD RS NC 002 - CADENCE® Non-Cyclonic

Notes:

- Maximum walling spans comply with both strength and serviceability wind requirements.

- Minimum steel support 0.55mm BMT G550.

- Maximum stiffened overhang for walling is 100mm for all gauges.

Installation

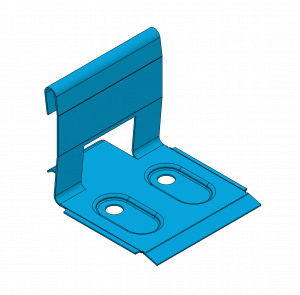

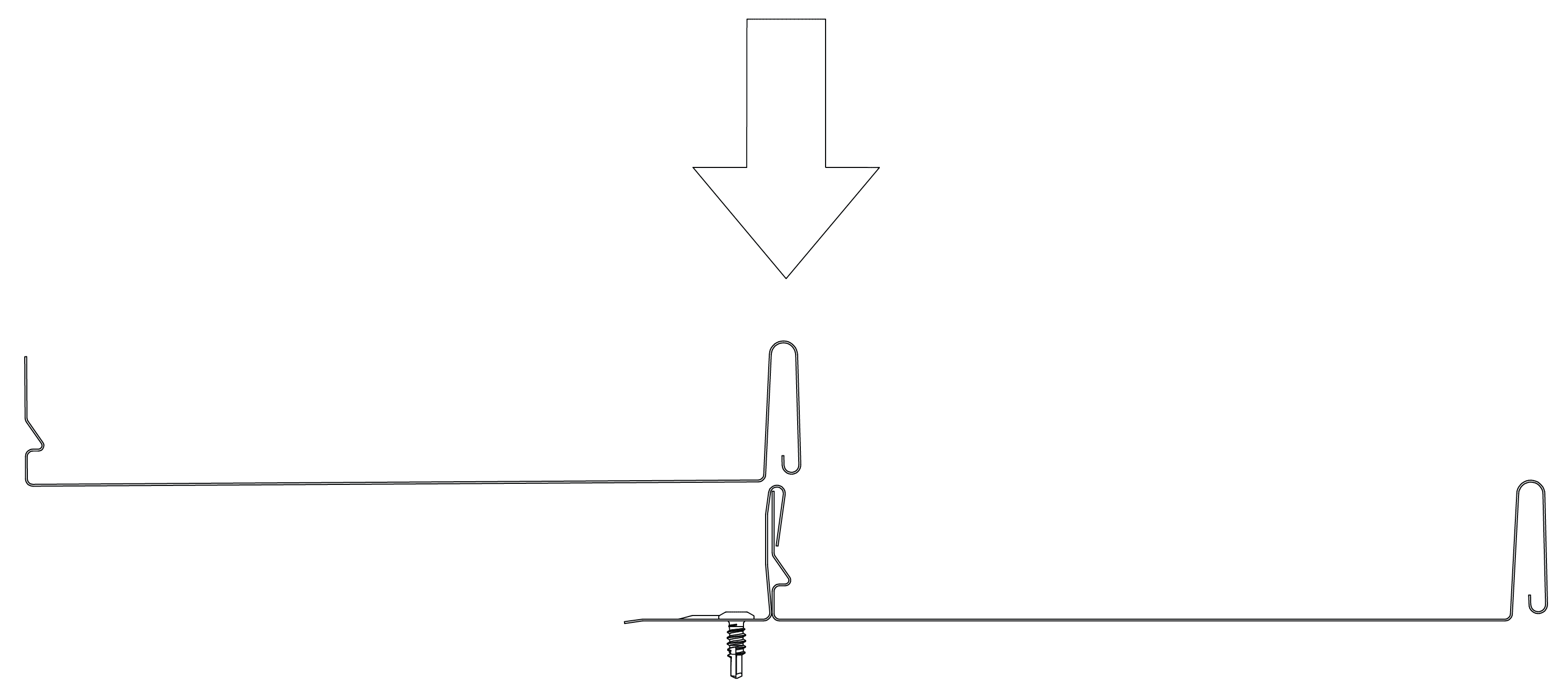

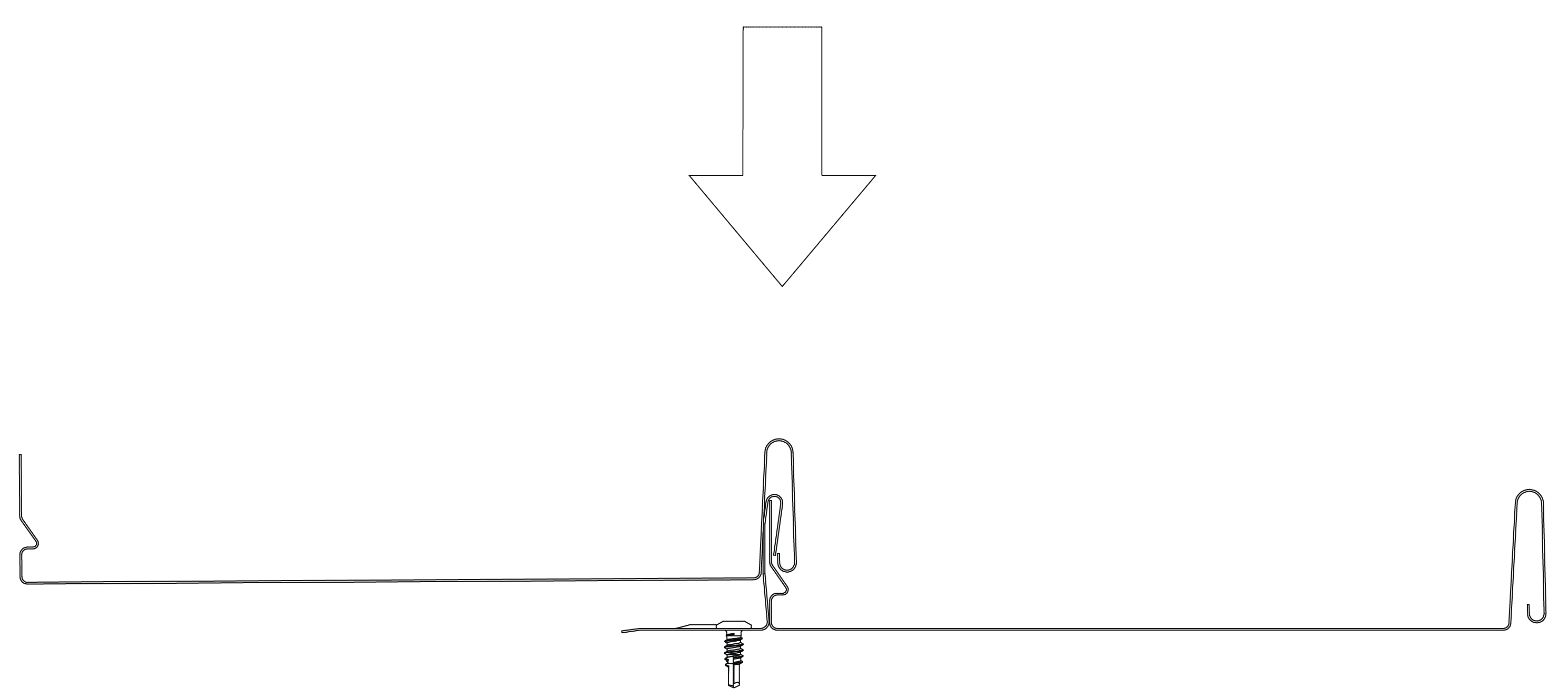

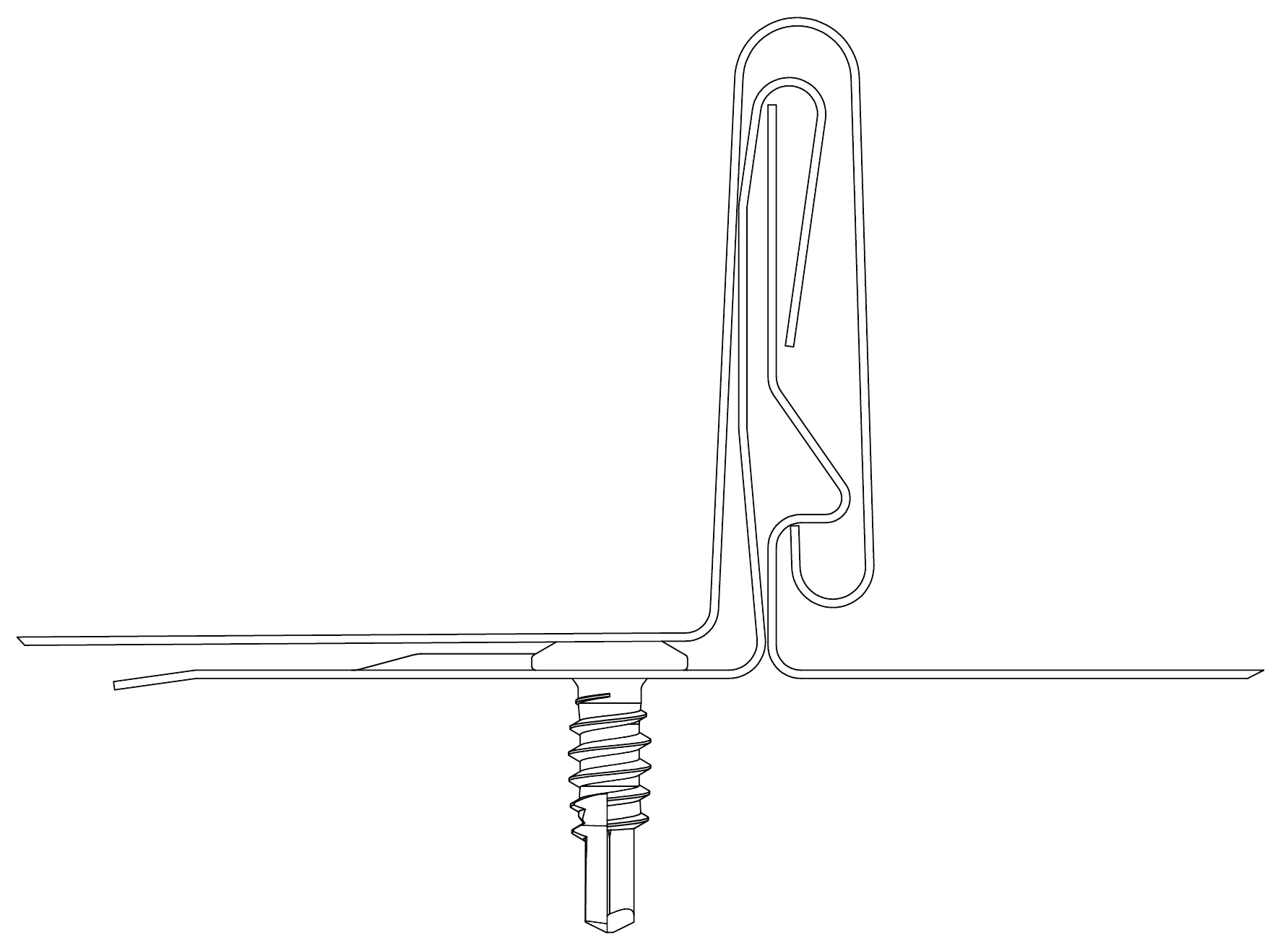

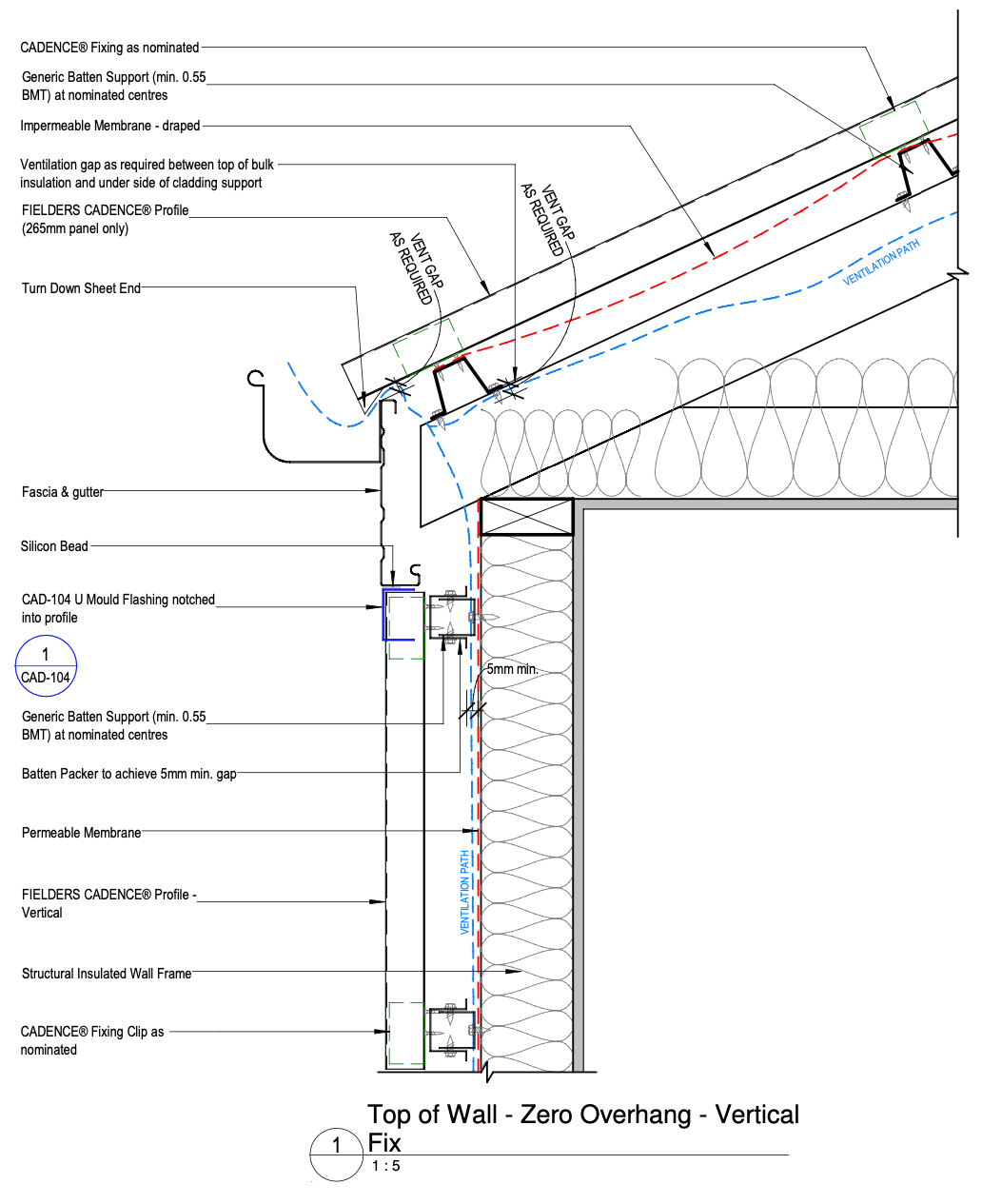

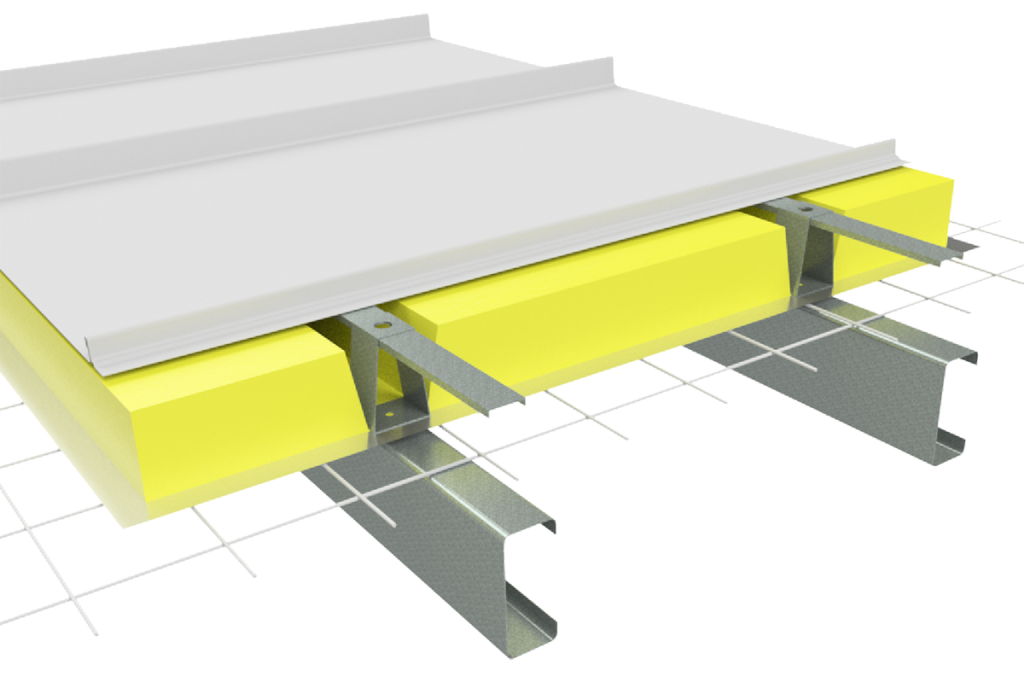

Fielders Cadence® is affixed using concealed Stainless Steel brackets to either plywood or batten supports. This provides additional fixing security whilst allowing longer sheet lengths to expand and contract in accordance with thermal loads. See Figures PR ID NC 003-007.

Recommended Fasteners

| Supports | Recommended Fastener (without insulation) |

| Steel 1.5mm BMT | 2 x 10g-16x16 Tri-Fixx Flat head metal screw with minimum class 3 coating |

| Plywood | 3 x 10g-12x25 Flat head type 17 metal screw with minimum class 3 coating |

| Timber | 3 x 10g-12x25 Flat head type 17 metal screw with minimum class 3 coating |

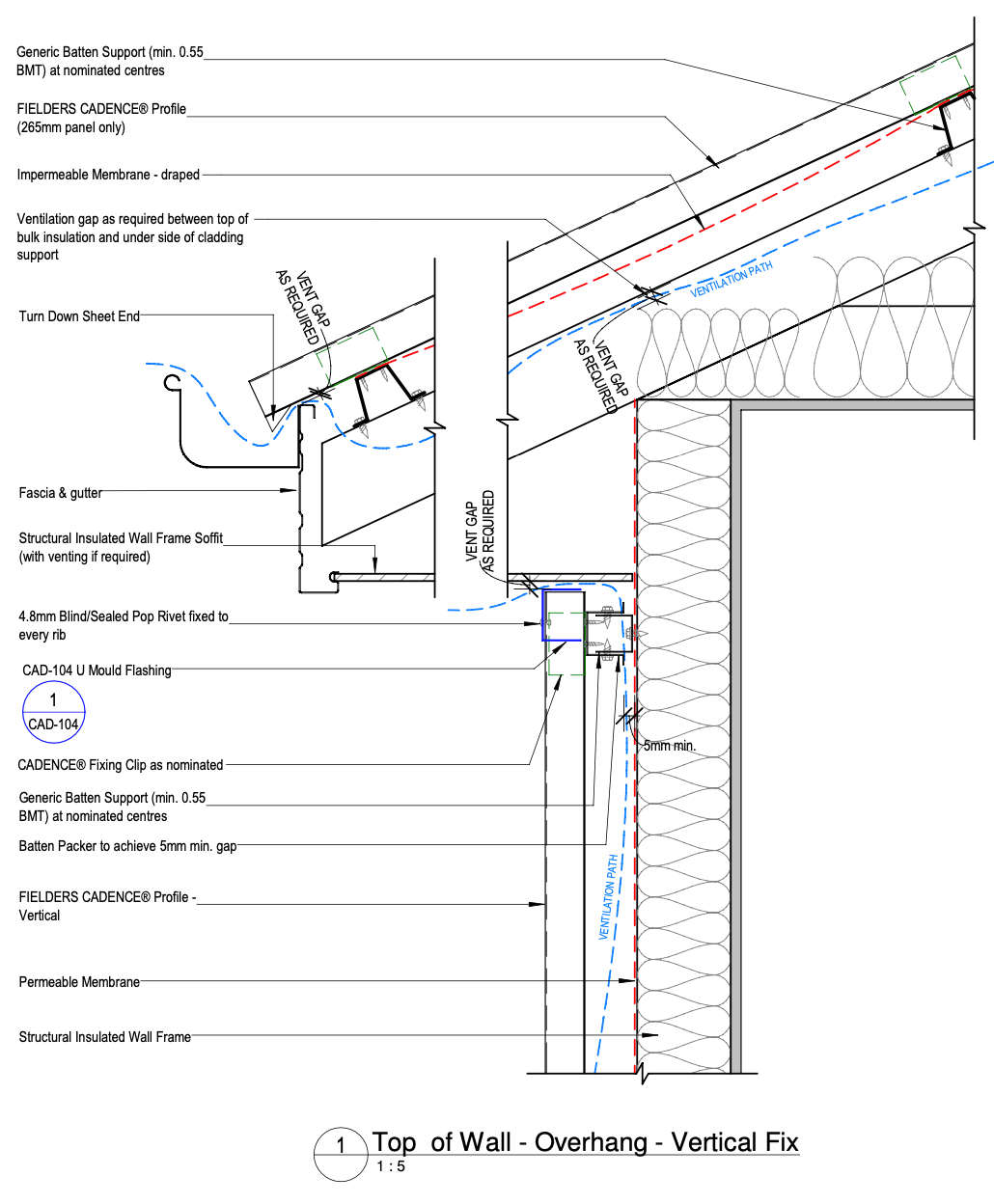

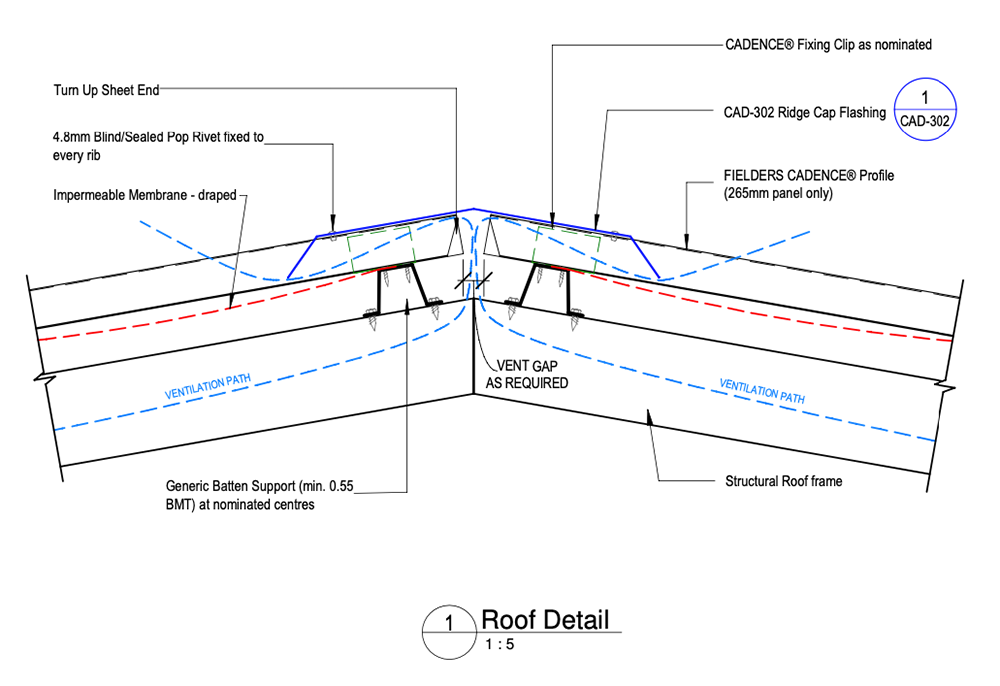

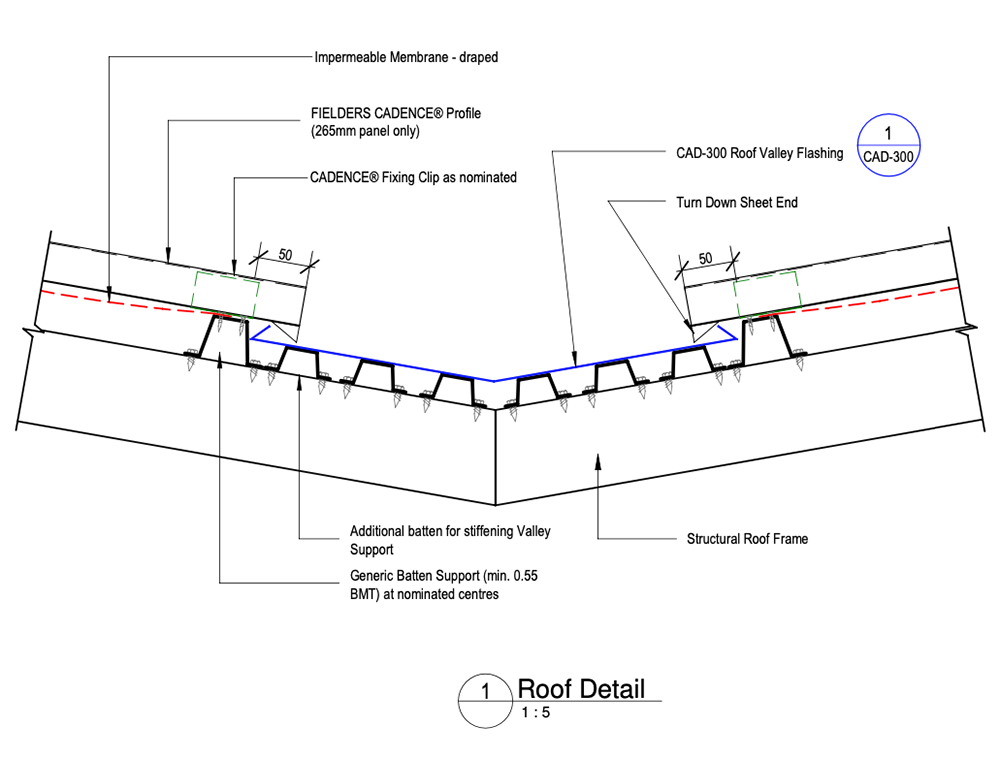

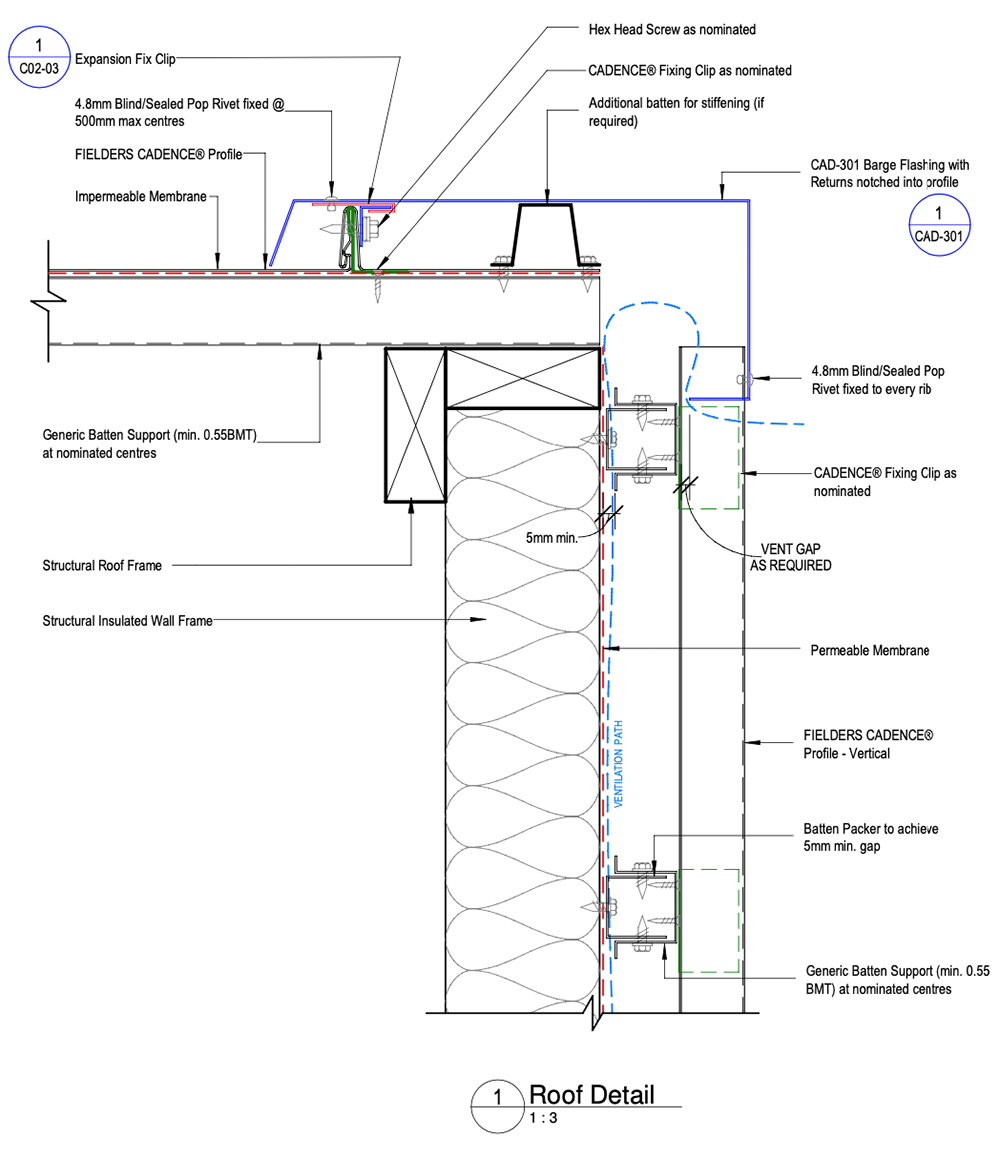

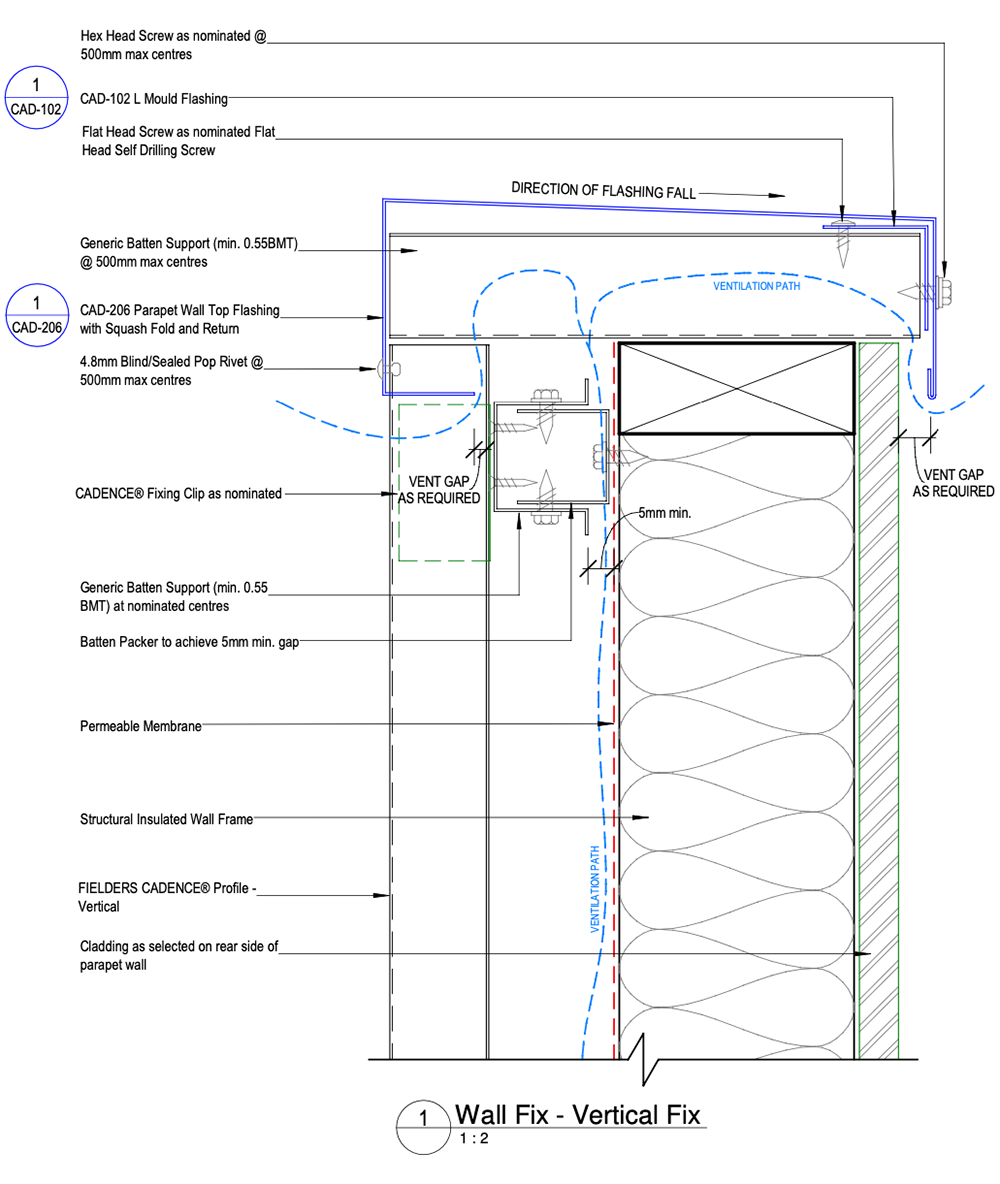

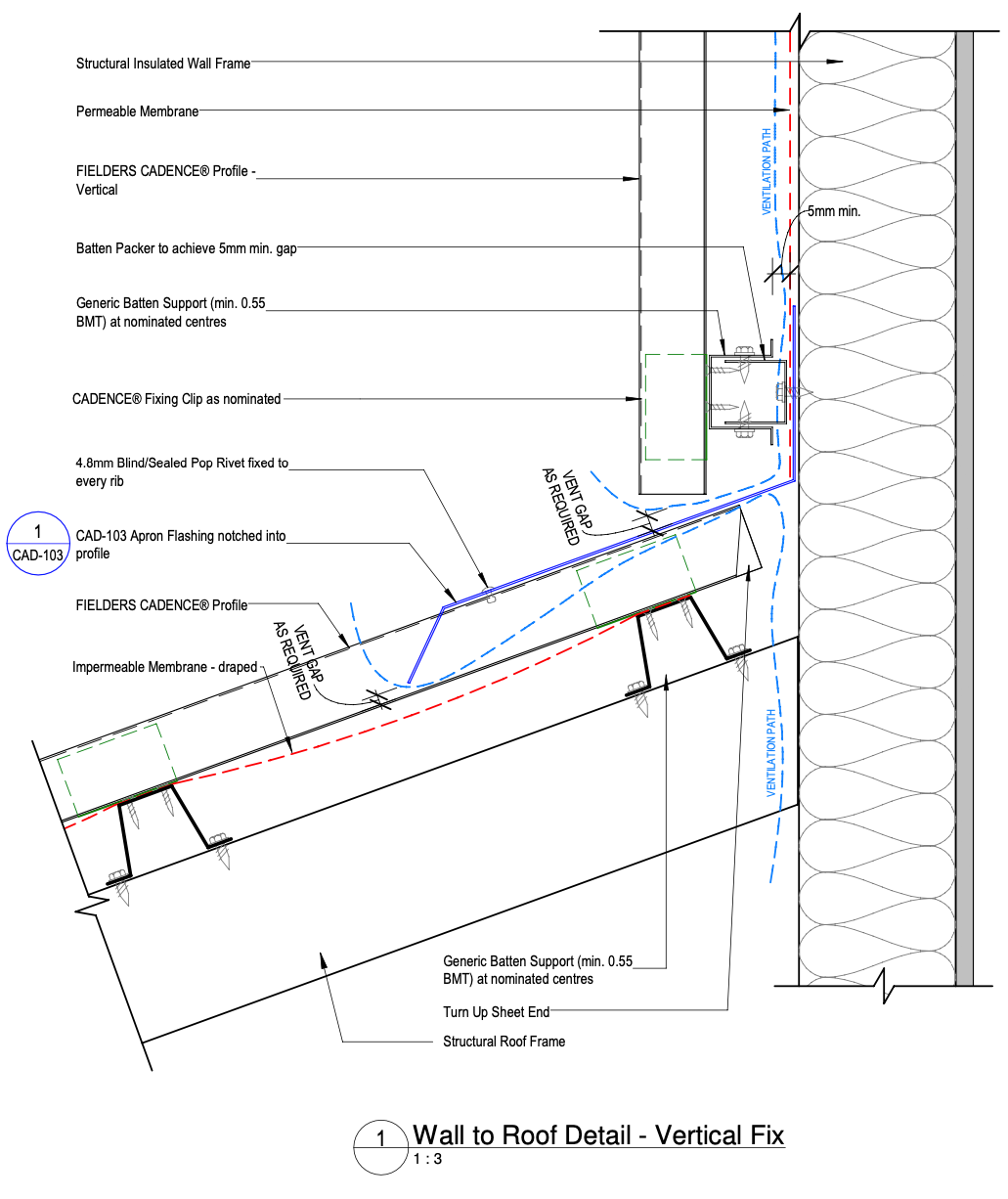

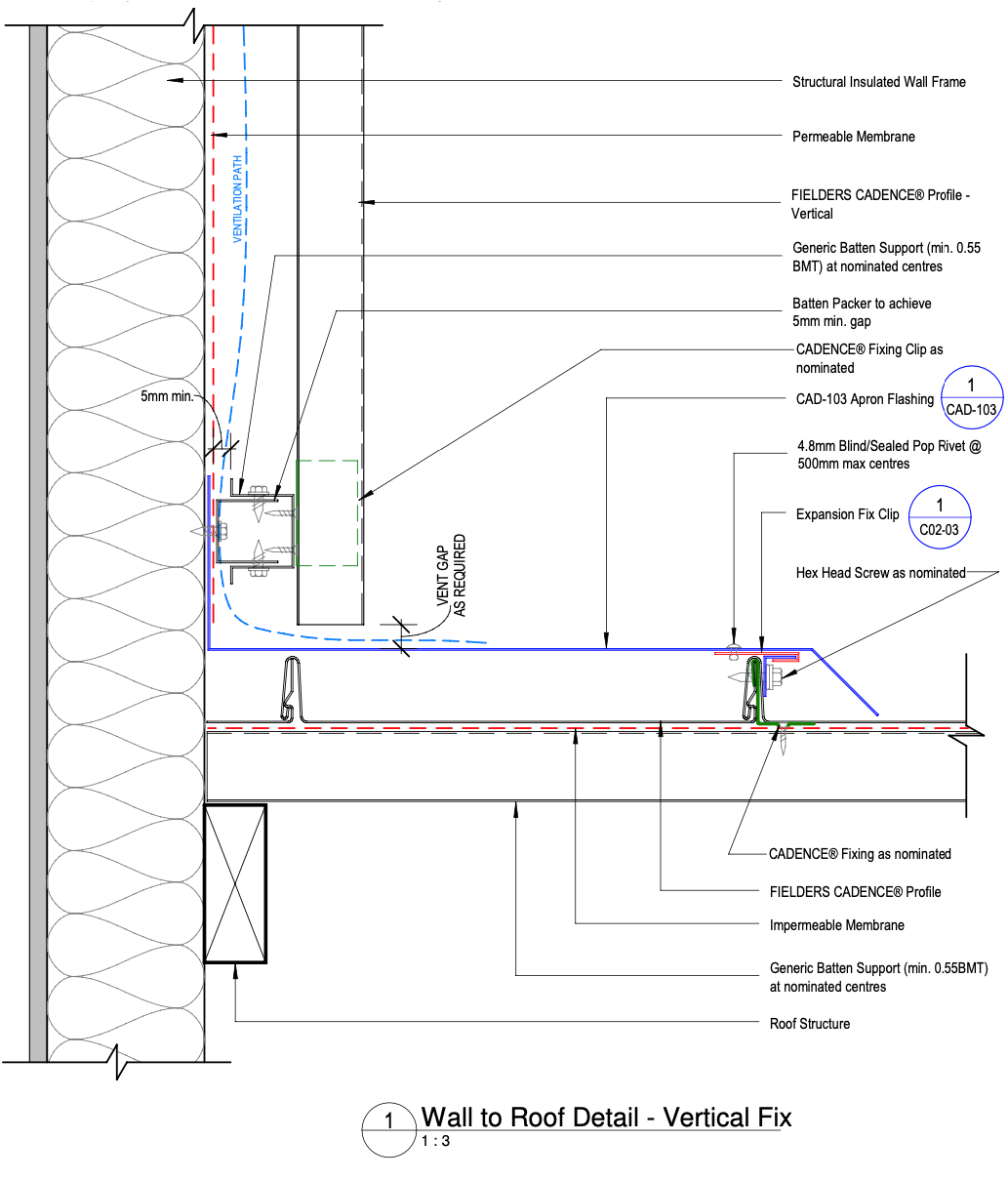

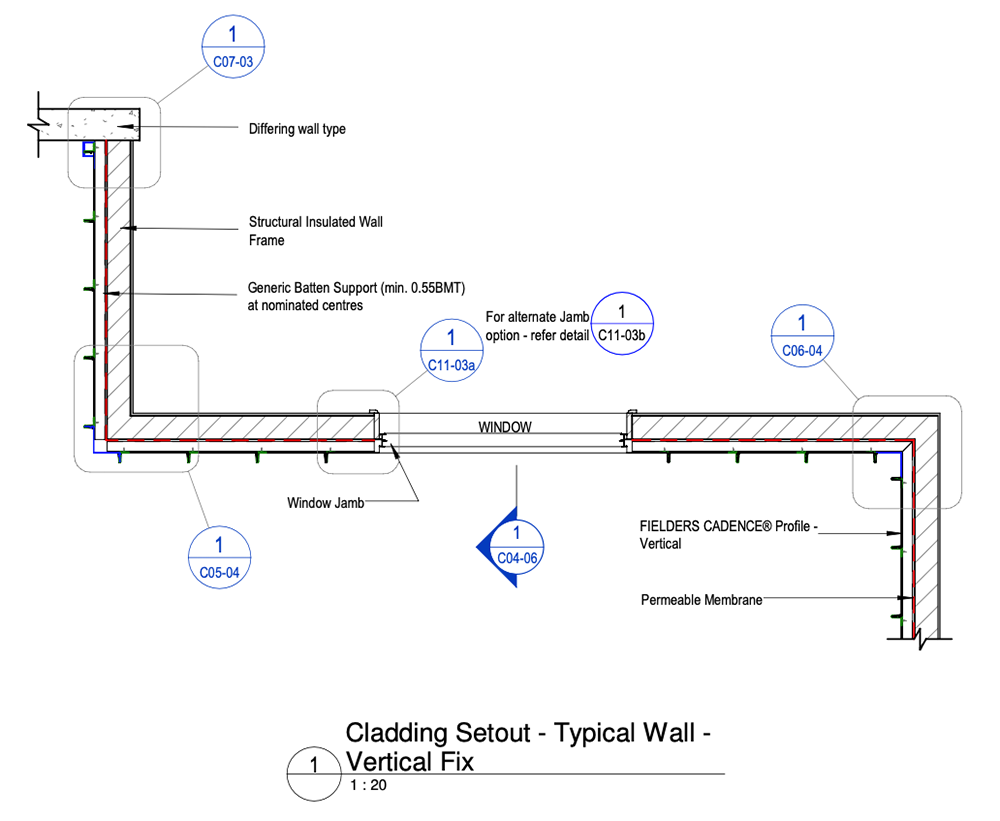

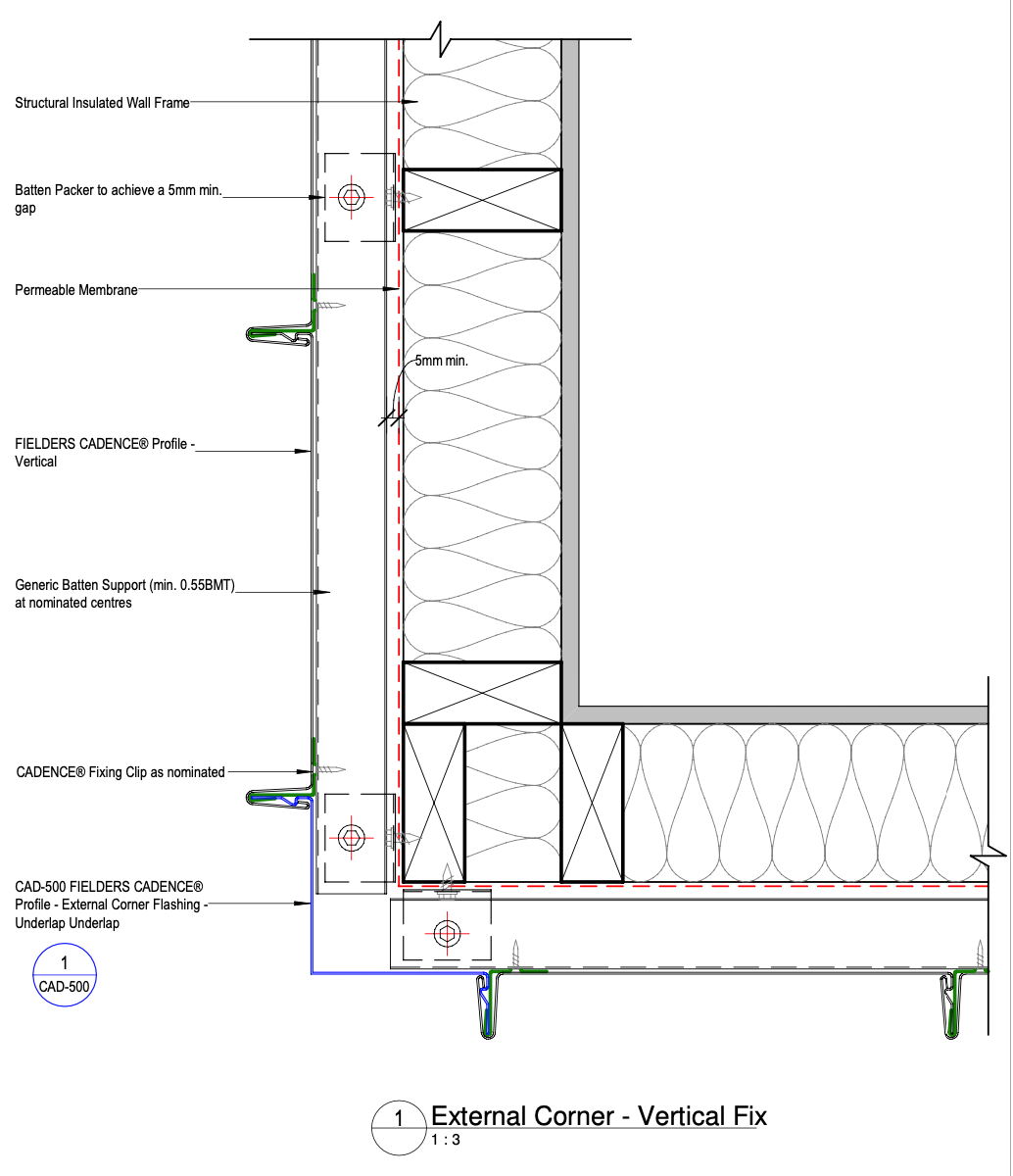

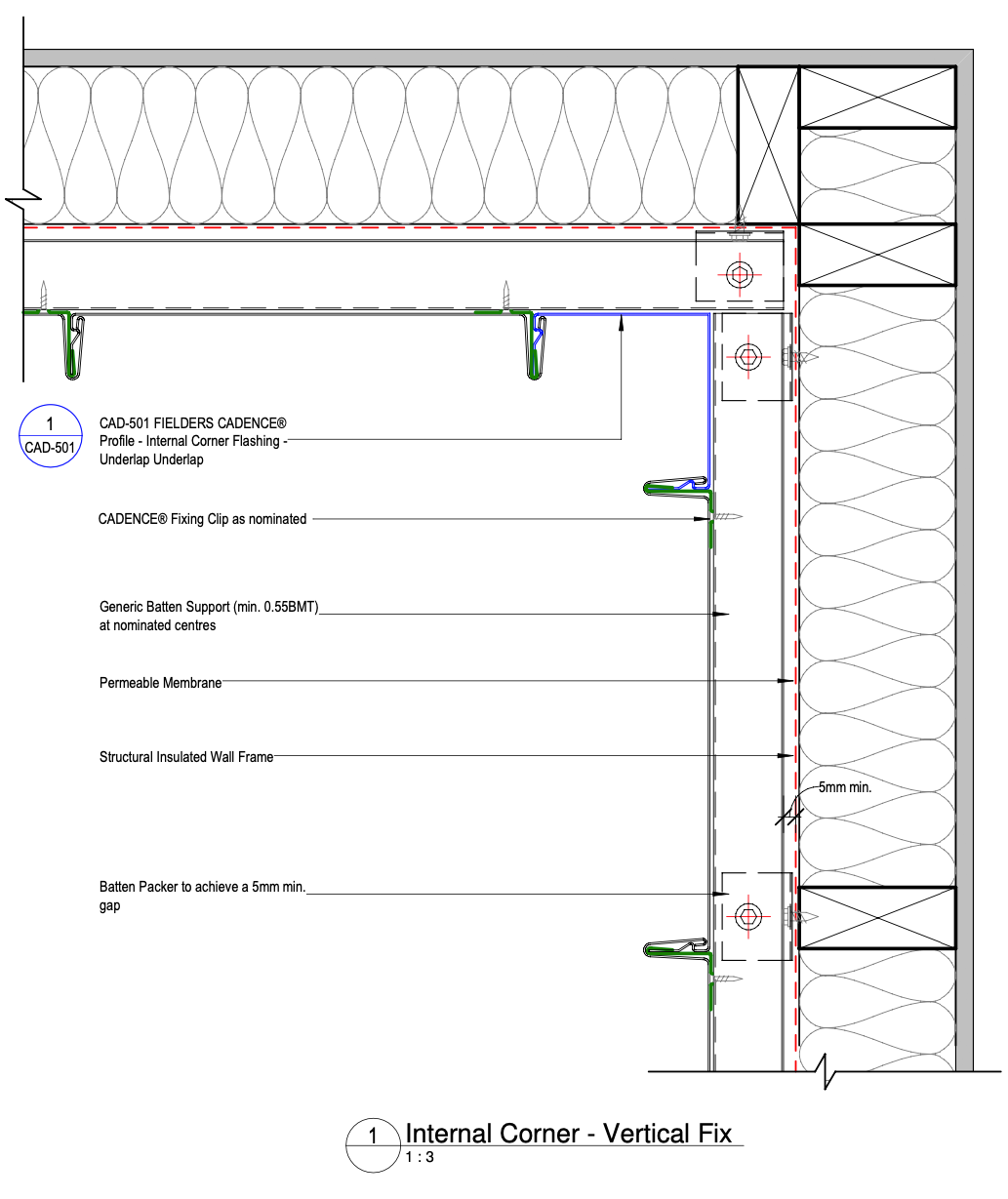

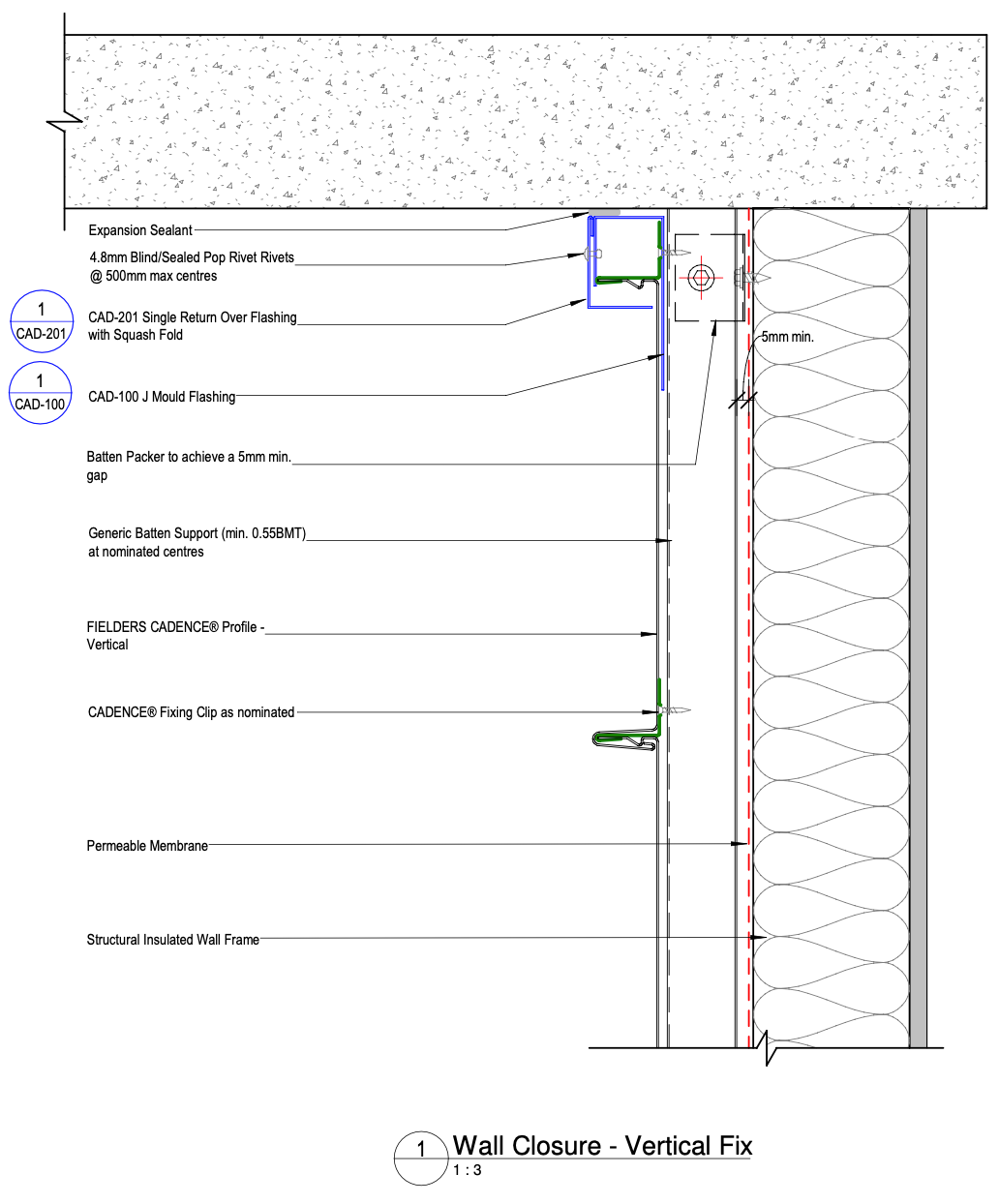

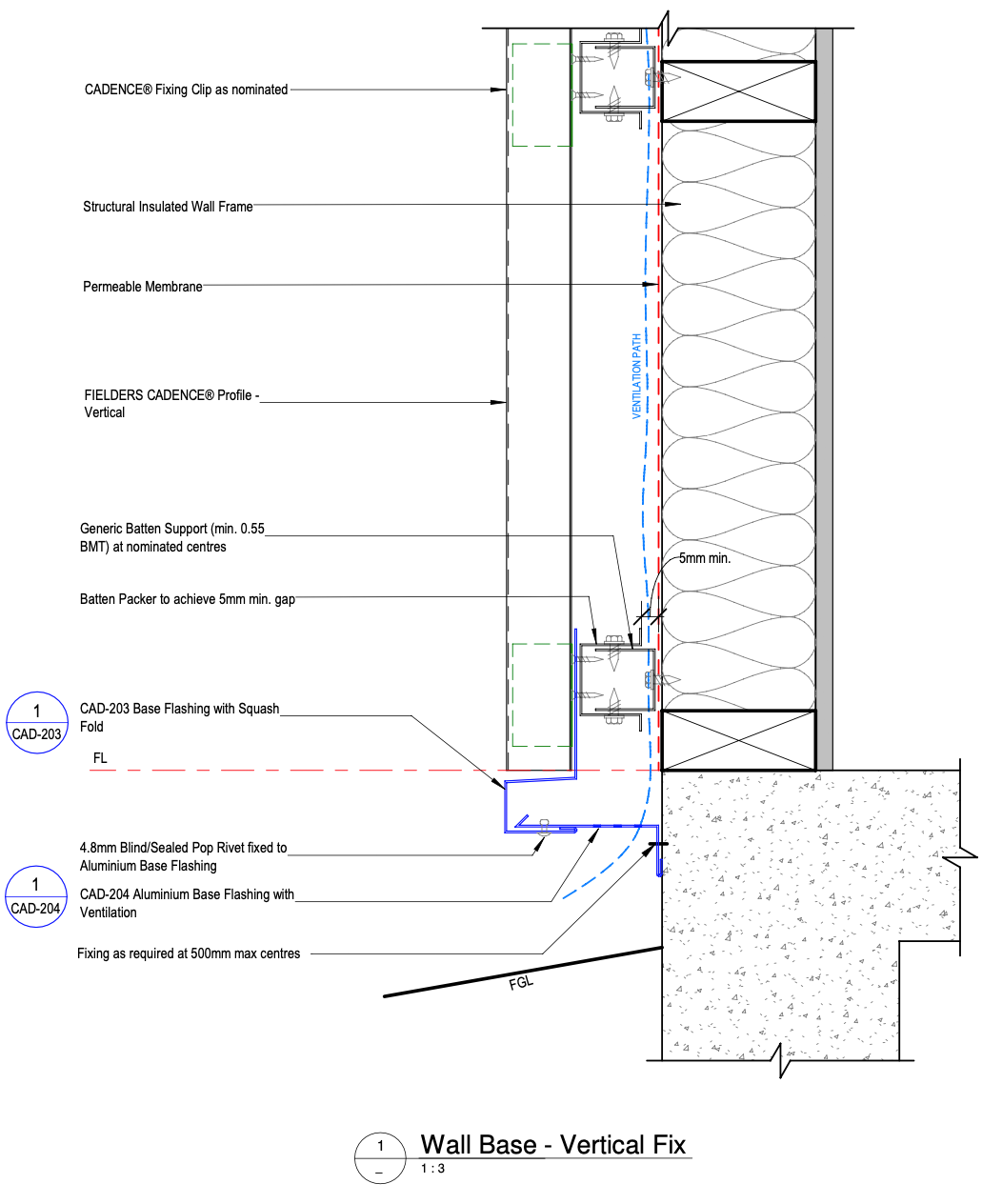

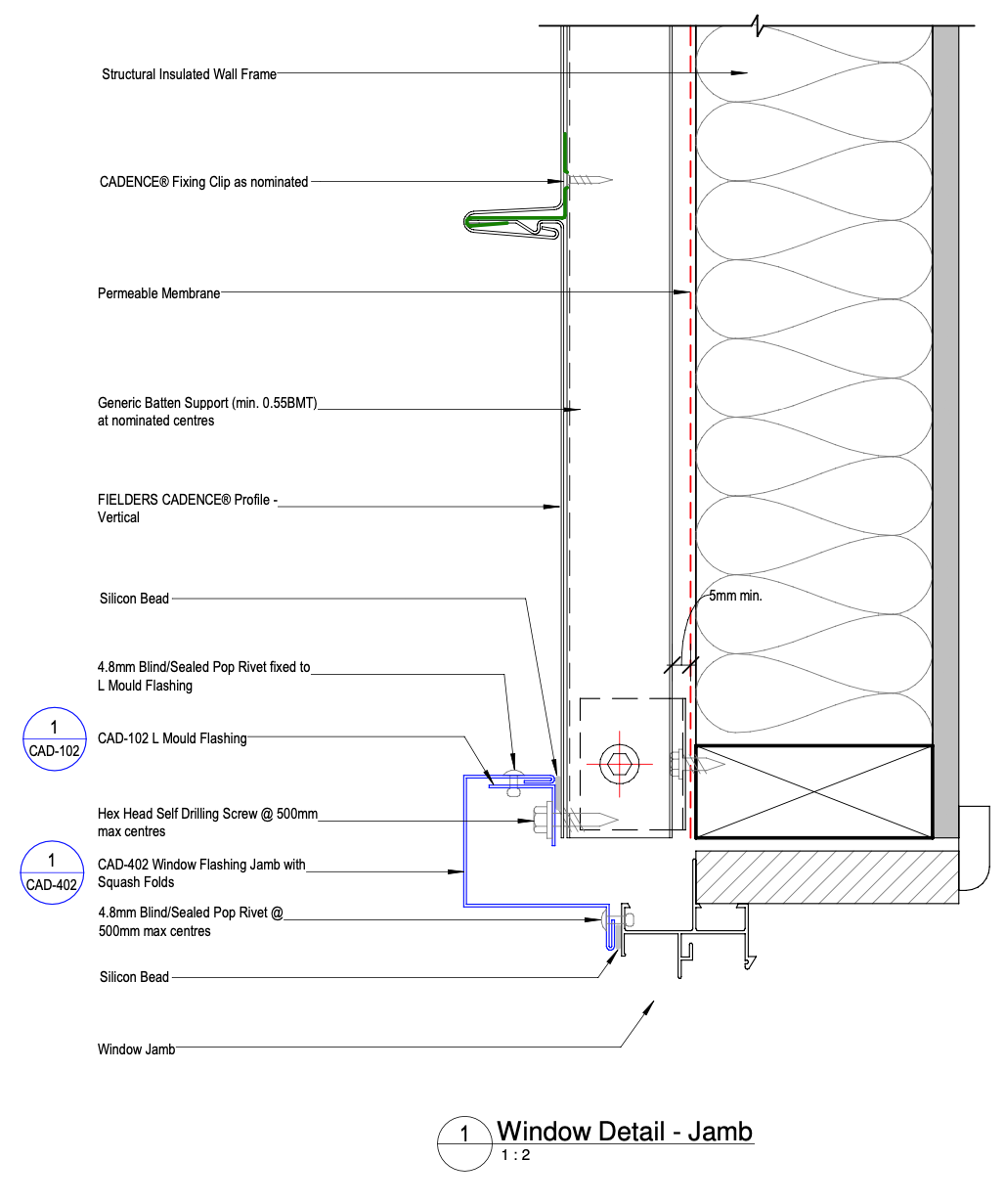

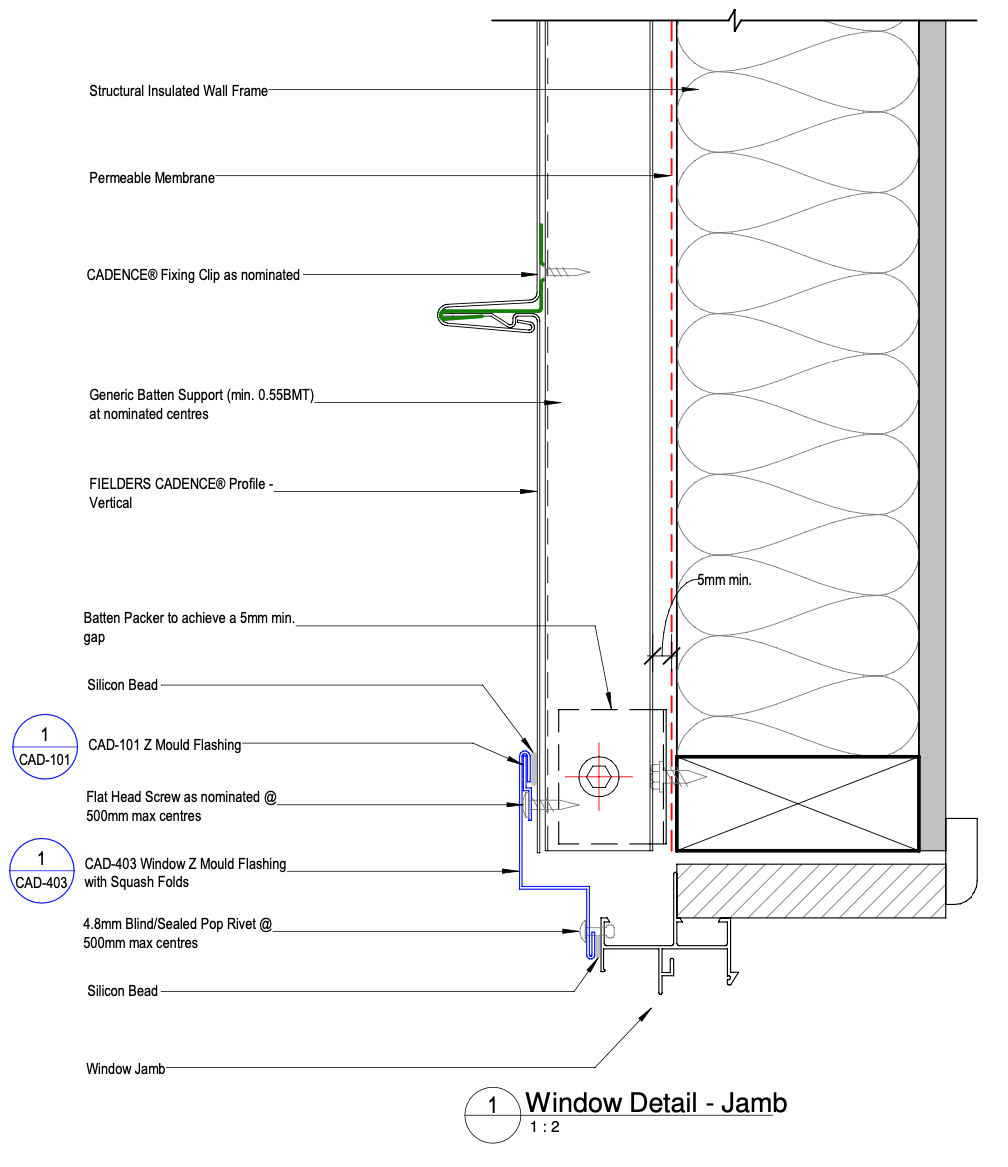

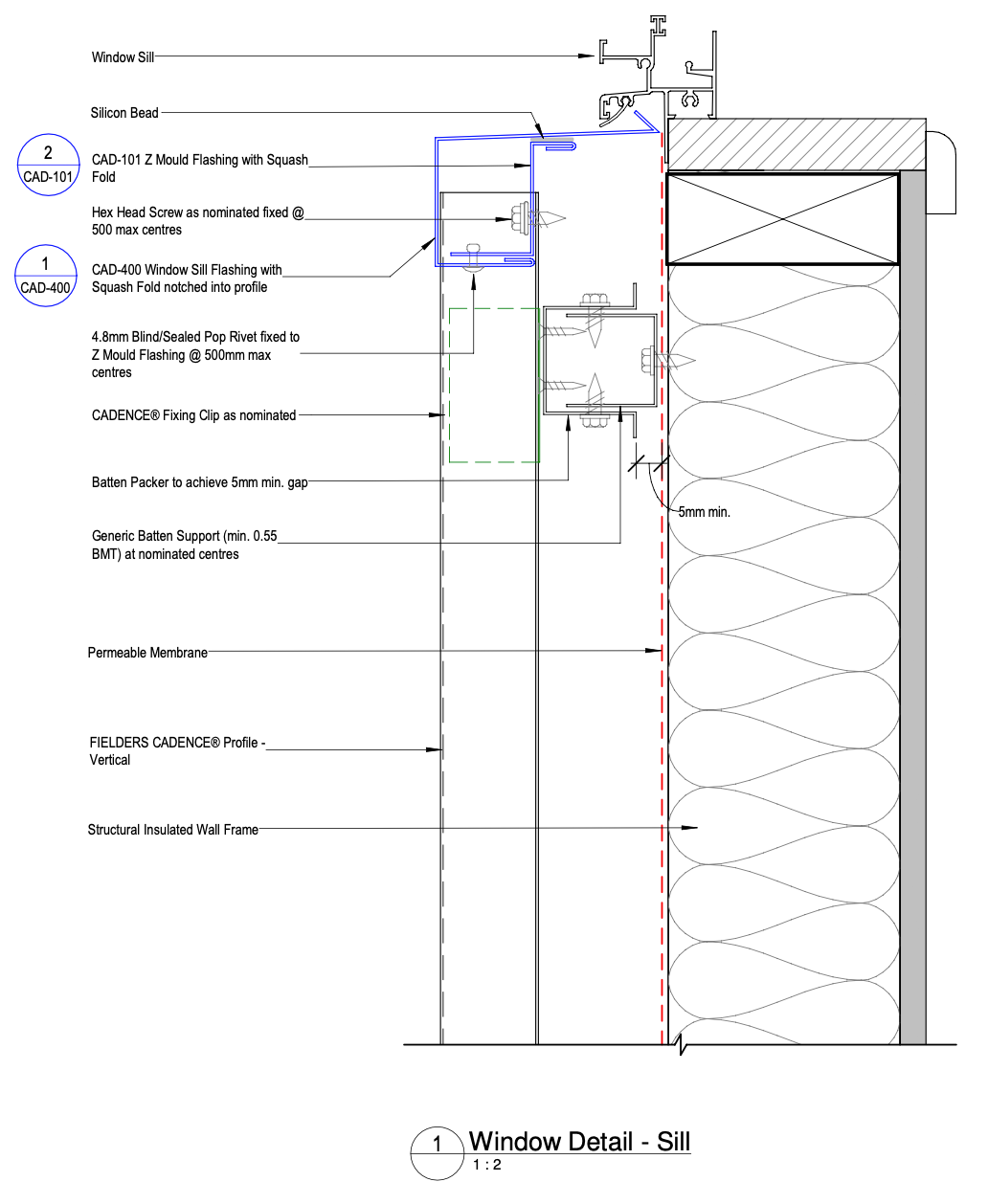

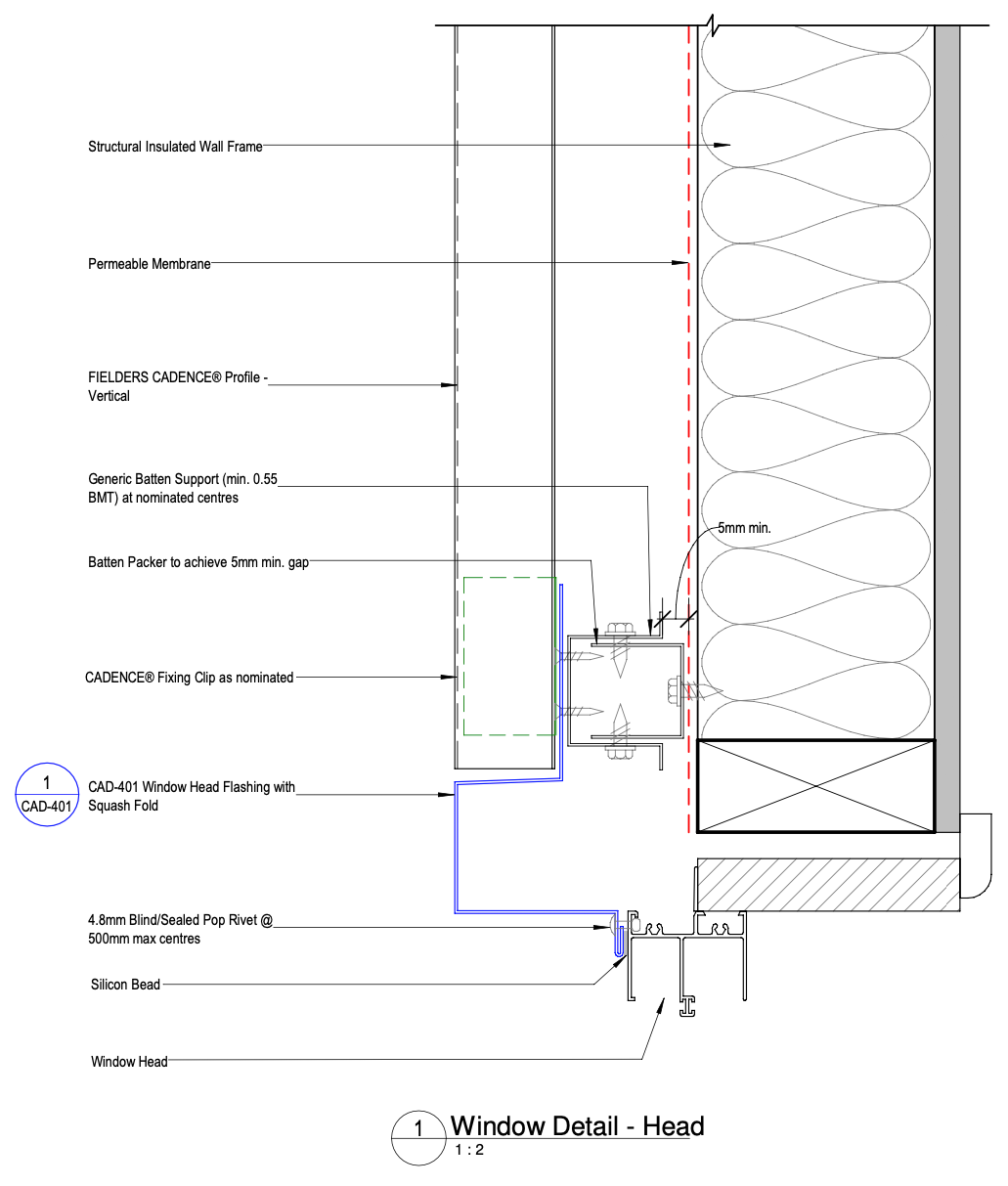

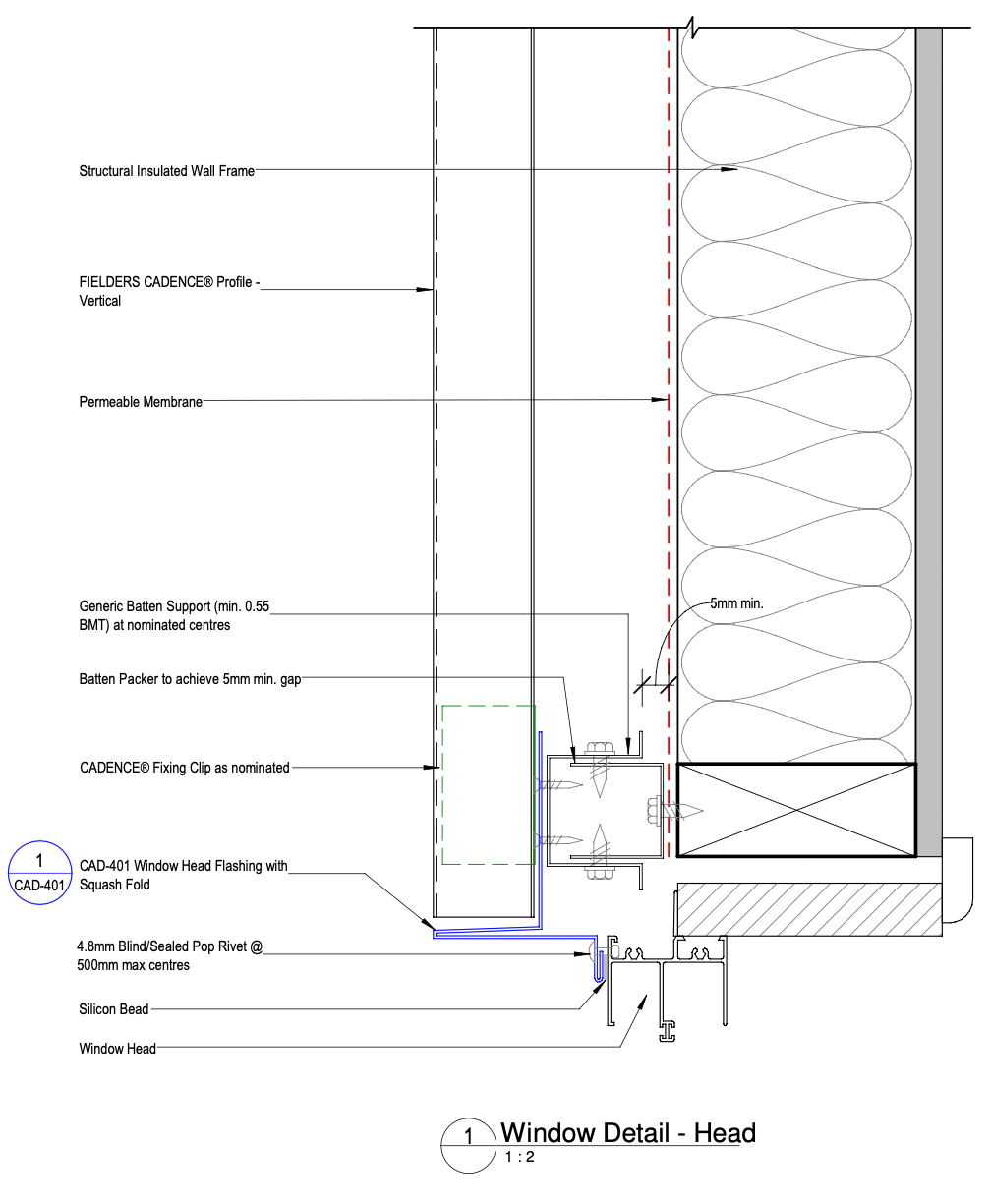

Construction Details

Refer to Prominence™ details for common Opening, Corner, Parapet and Toe mold, Ridge, Valley and Barge flashing details here.

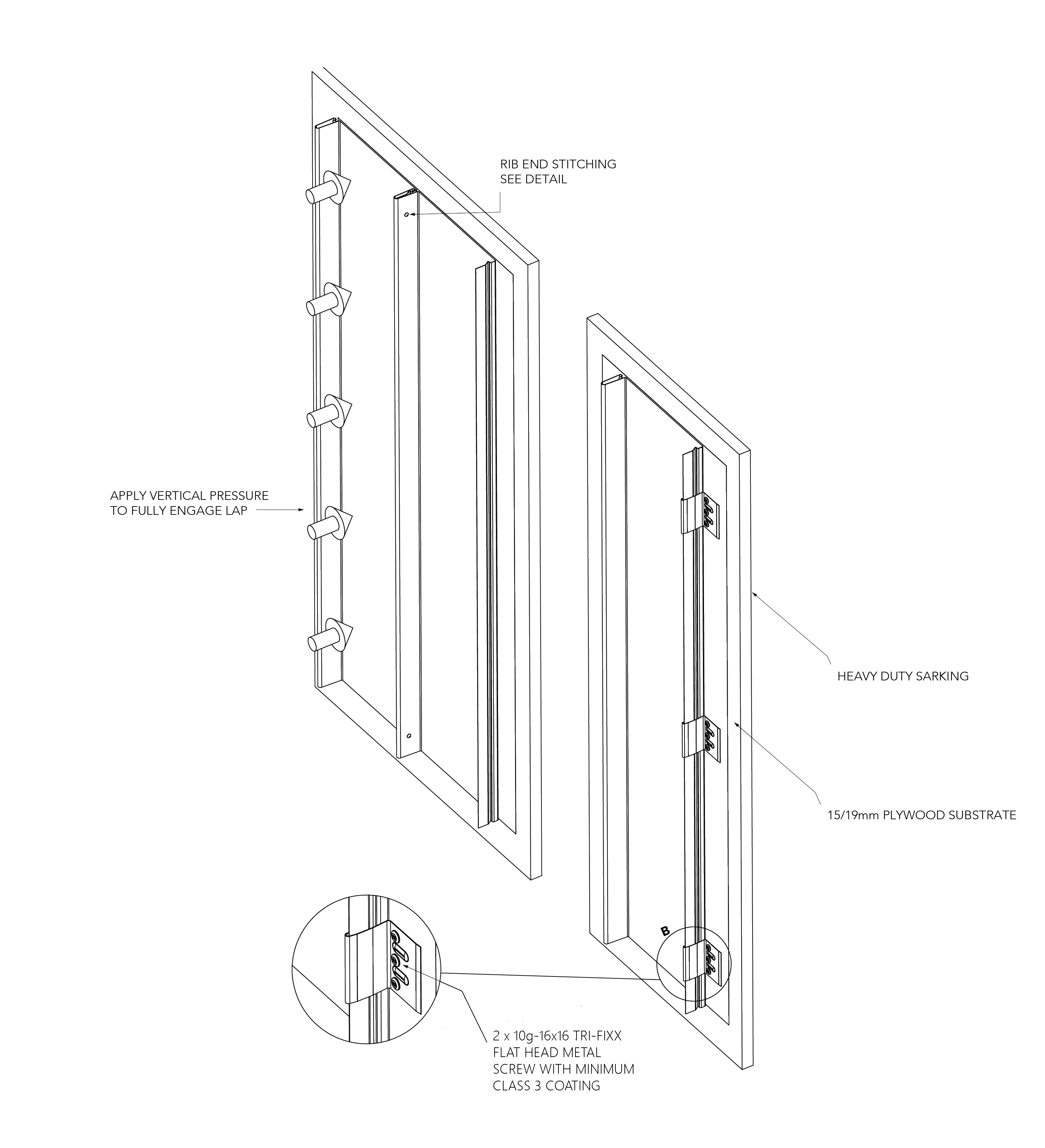

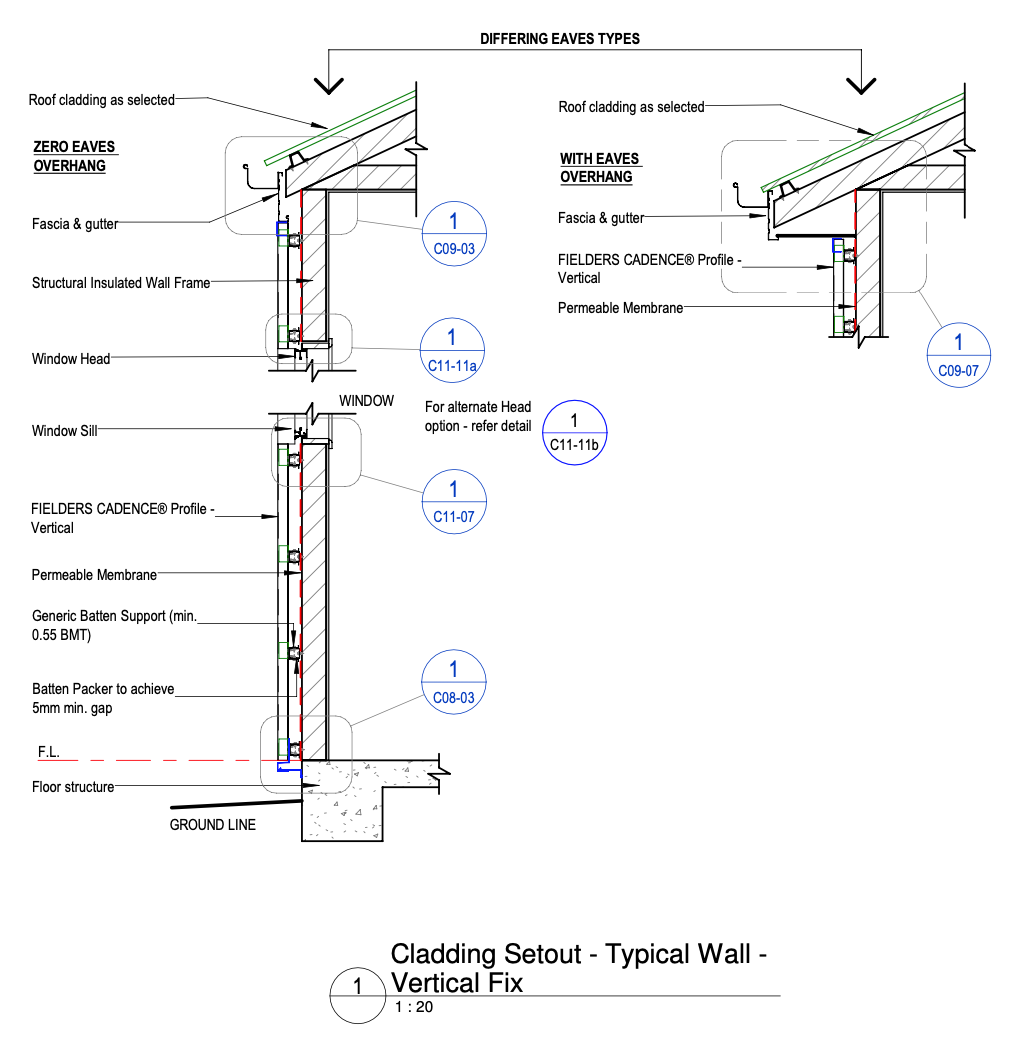

Wall Layout — Vertical

Figure CD ID NC 010

Notes:

*For walling configurations plywood is optional. CADENCE® can be fixed directly to the framing system provided fixings do not exceed those specified in Table PR RS NC 001 (closer spacings may be required in high wind zones, confirm with Fielders). In areas where impact of the material is possible, plywood is recommended to minimise damage to the profile.

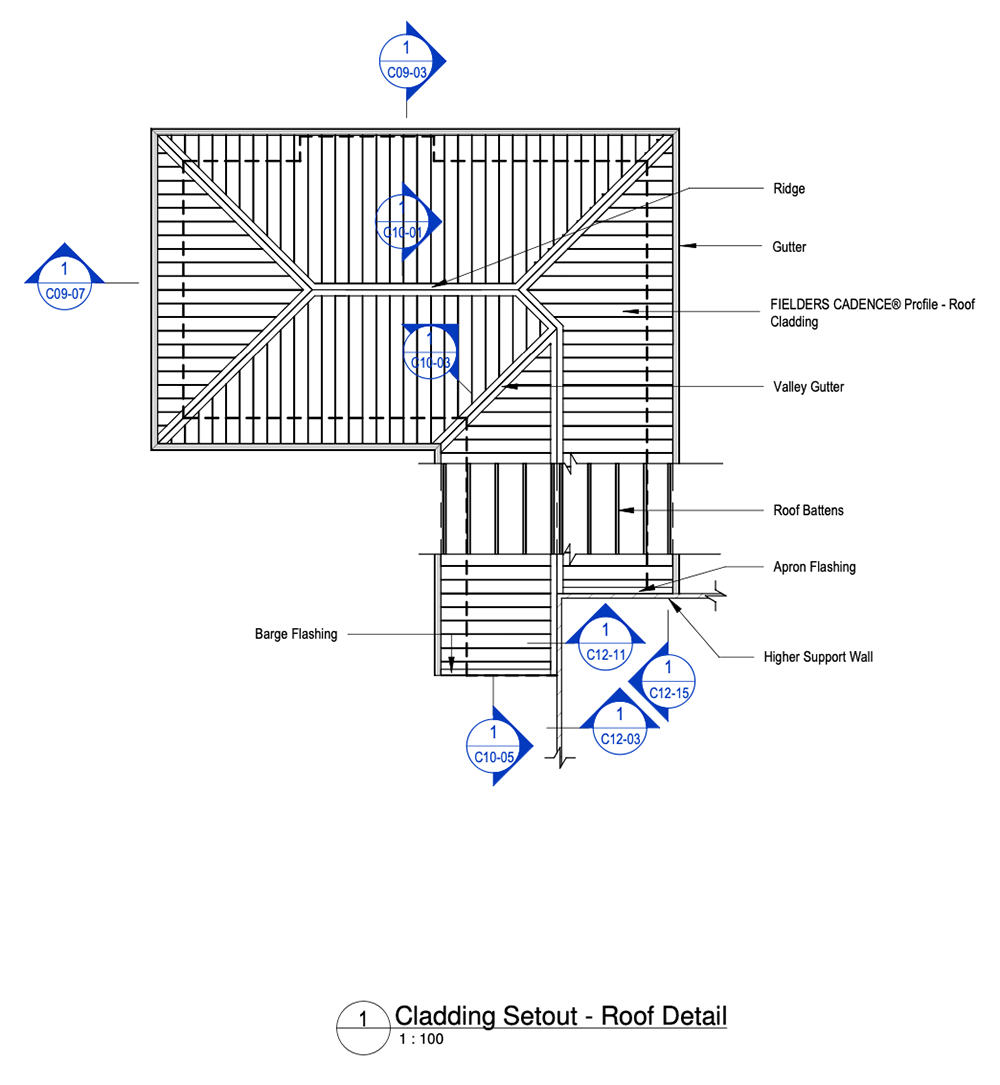

Roofing Layout

A full range of construction details are available, covering installation on ply from https://specifying.fielders.com.au/downloads/

A full range of construction details are available, covering both horizontal installation and installation on ply from https://specifying.fielders.com.au/downloads/

Ancillary Installation Details

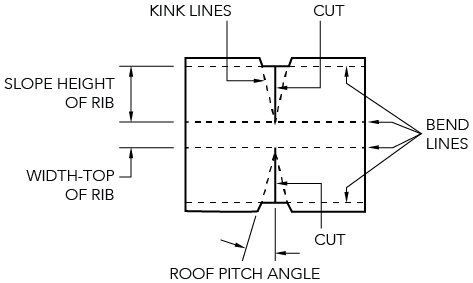

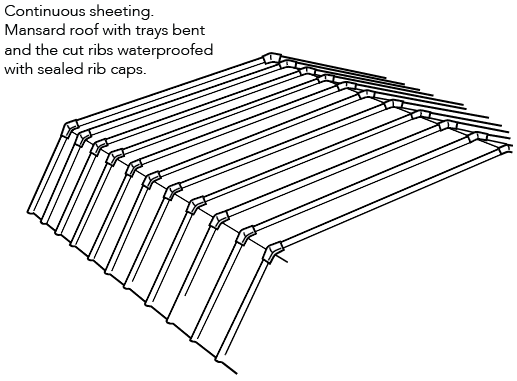

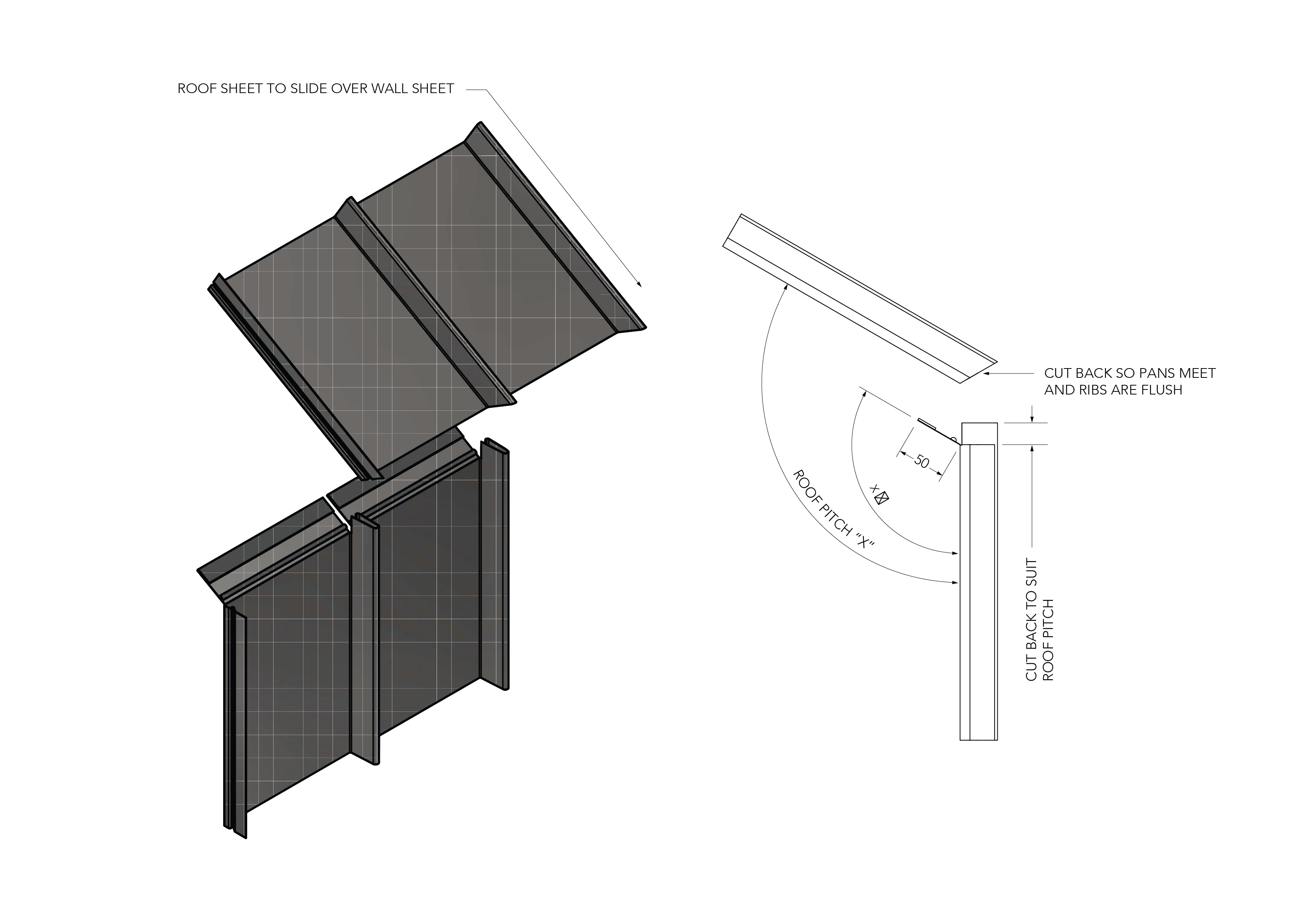

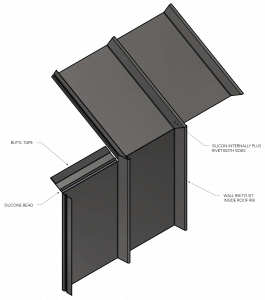

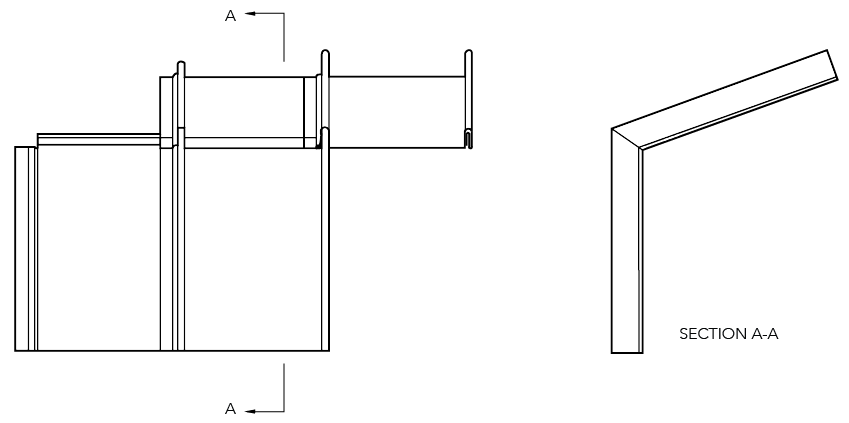

Roof to Wall Mansard Connection Detail 1

Roof to Wall Mansard Connection Detail 2

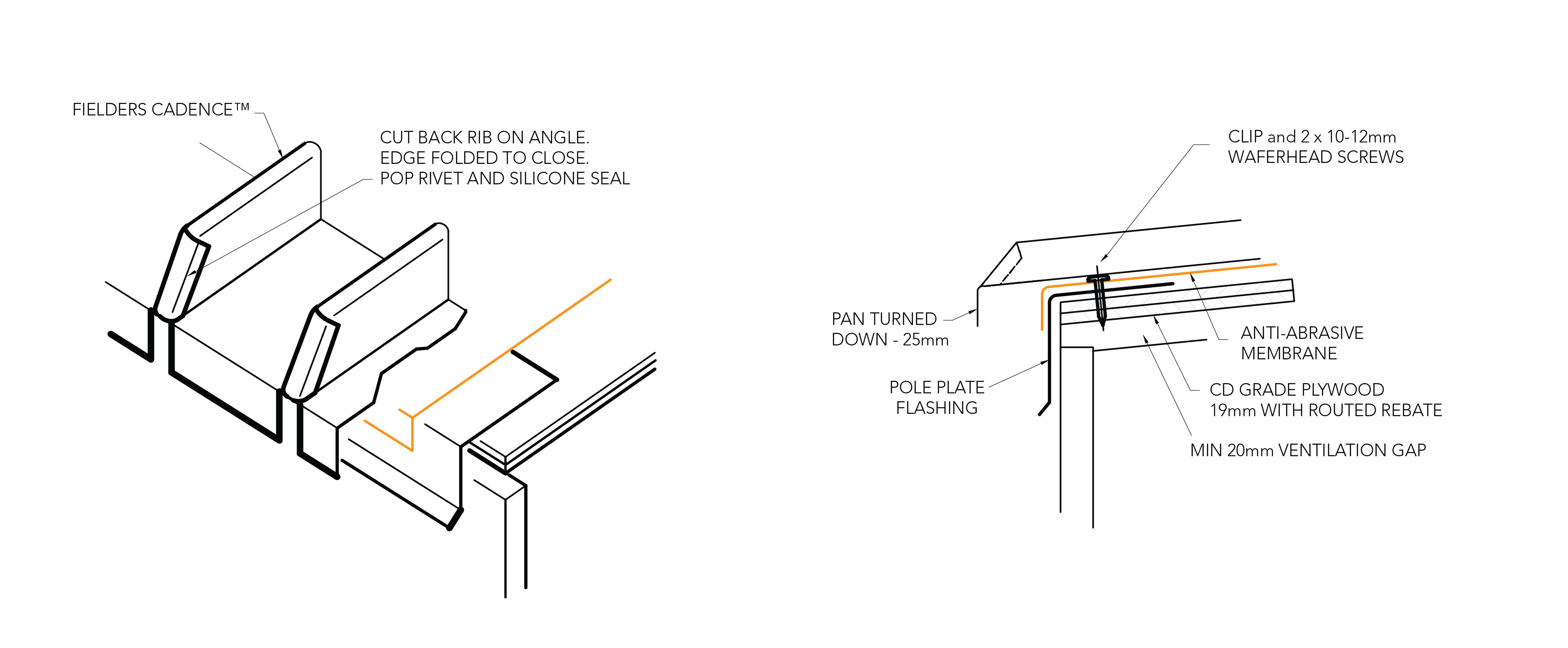

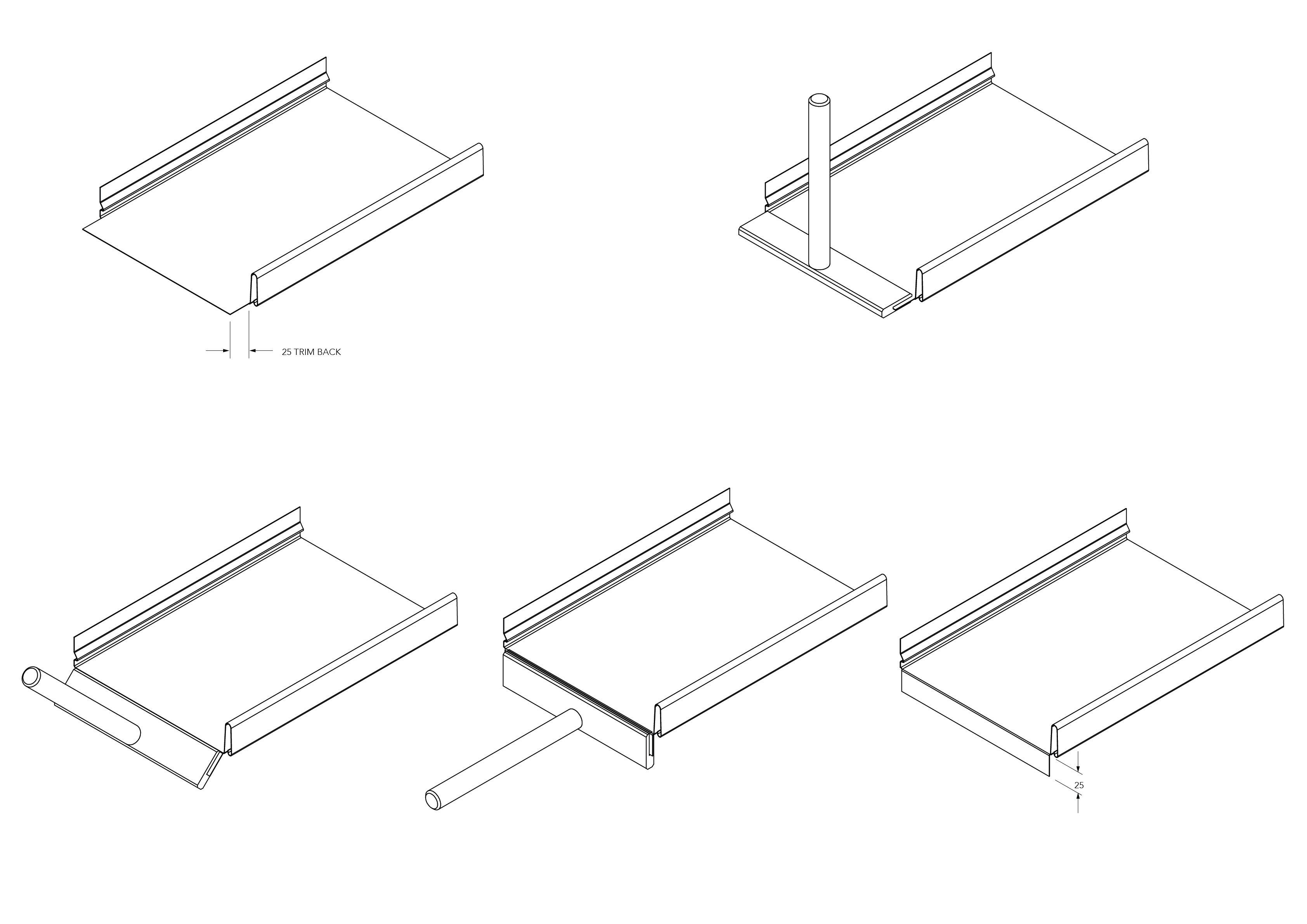

Installation Details: Typical Panel Turndown

- Panels requiring field hemmed ends should be fabricated 25mm longer than the finished panel length. Valley conditions must be field cut to the appropriate angle.

- Cut back panel joints 25mm.

- Place protruding pan into the panel hemming tool. The front edge of the tool must rest against the notched joint legs on both sides.

- While maintaining pressure against the panel joints, rotate the hemming tool as close to 90° as possible.

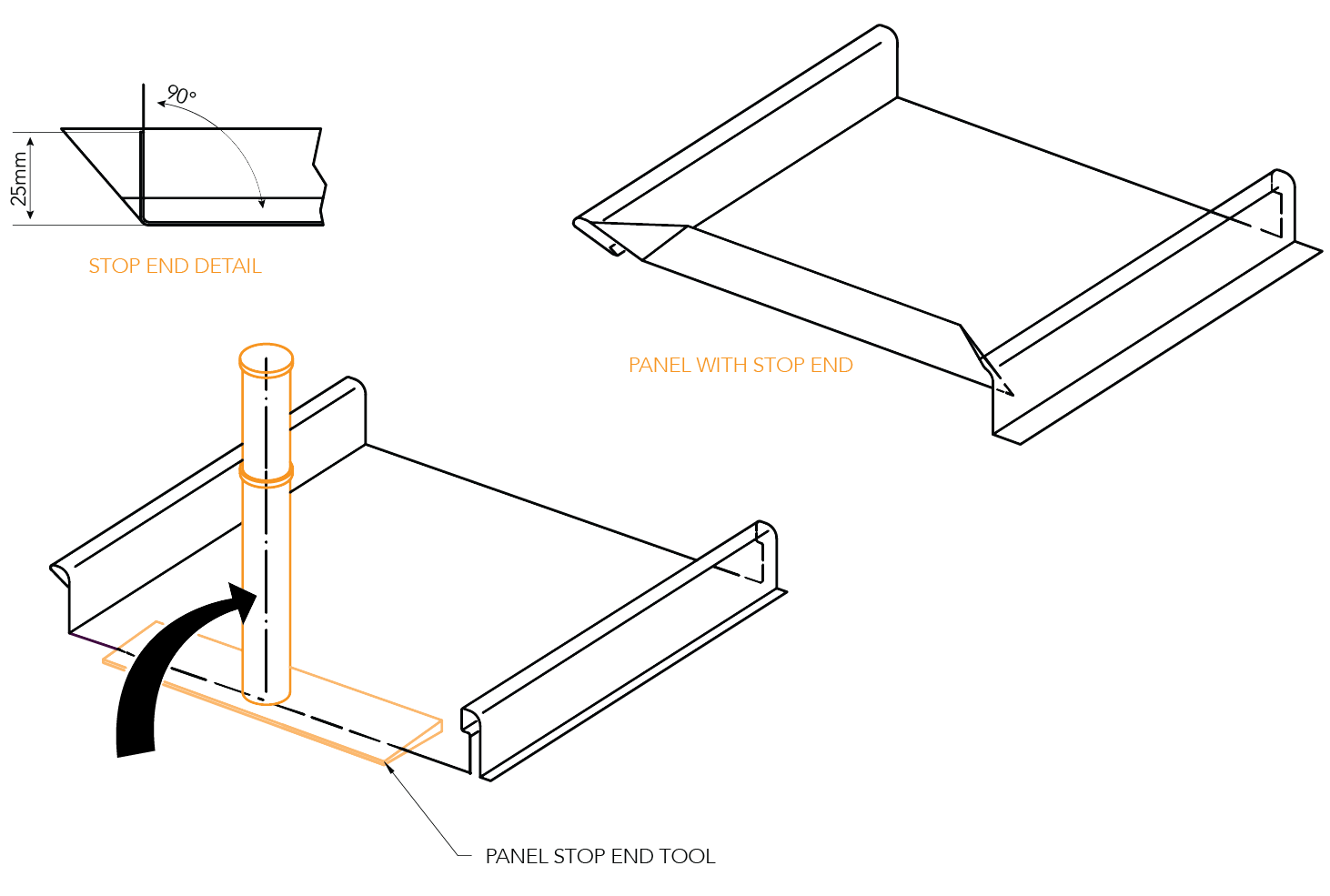

Installation Details: Typical Stop End

- Place pan into the panel stop end tool. The front edge of the tool must rest between the ribs.

- While maintaining pressure against the panel, rotate the stop end tool as close to 90° as possible.

- Inspect completed bend.

Oil Canning

Oil canning is a characteristic of thin gauge cold formed metal products which is caused by internal stresses within the metal. There are many factors that influence the degree of oil canning and more information can be found here.

To assist in minimising the effects of oil canning in Cadence™ it is recommended that panel lengths are kept to under 12m. If longer lengths are required please discuss with Fielders.

For further information about Oil Canning, please refer to our Oil Canning reference page.

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thickness up to 50mm are installed the screws may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed in to. For timber the screw must penetrate the timber.

When insulation is required in conjunction with Finesse® profiles, Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising any bulging in the the profile caused by the insulation.

Insulation blankets and batts can cause wide flat pan cladding to bow out between the supports, between fasteners along the support, or bow the pans. For insulation blankets and batts as well as more dense glass wool and rock wool, and thicker insulation, spacers are recommended.