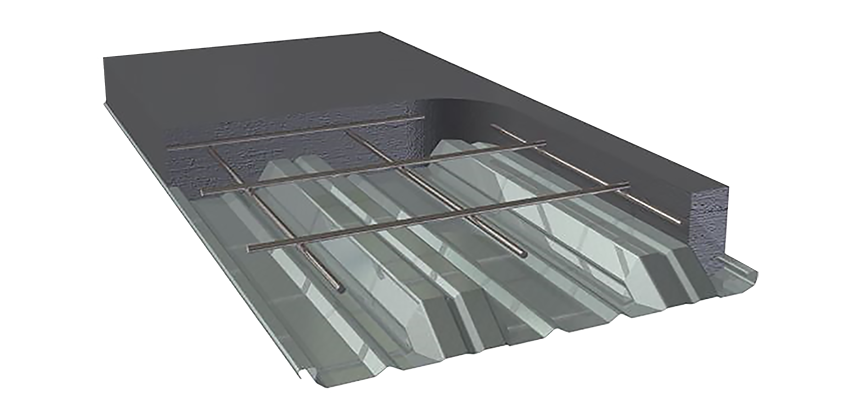

KF40® Features and Benefits

| Feature | Benefit |

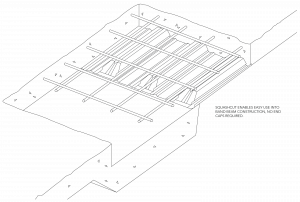

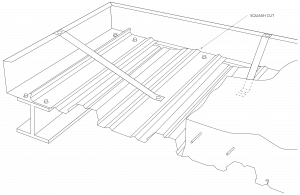

| SquashCut™ ends | No end caps needed. Also provides rigid and secure platform during construction. |

| Unique off-set lap | Enables shear studs to be placed centrally in the pan in the most optimal position. |

| Unique profile | Concrete savings up to 40kg/m2 (16mm off slab depth). |

| Lower 40mm height | Suitable for post-tensioning ducts. |

| Wide 742mm cover | Economical deck. |

| Strong re-entrant features | KF40® has been specifically designed to provide a strong and reliable shear bond performance giving strong composite slabs. |

Concrete Savings

KF40® Material Specifications

KF40® is manufactured from G550 (550 MPa Yield Stress) steel in a 3 pan profile with a Base Metal Thickness (BMT) of 0.75mm and 1.00mm. The galvanised coating thickness is a Z350 (350 g/m2) in accordance with AS 1397:2001.

| Material Properties | 0.75 BMT | 1.00 BMT |

| Mass Area – Average mass of 3-PAN deck per plan area (kg/m2) | 8.35 | 10.97 |

| Mass Linear – Mass of individual 3-PAN length (kg/m) | 6.19 | 8.14 |

| Zinc Coating (g/m2) (Z350) | 350 | 350 |

| Yield Strength (MPa) | 550 | 550 |

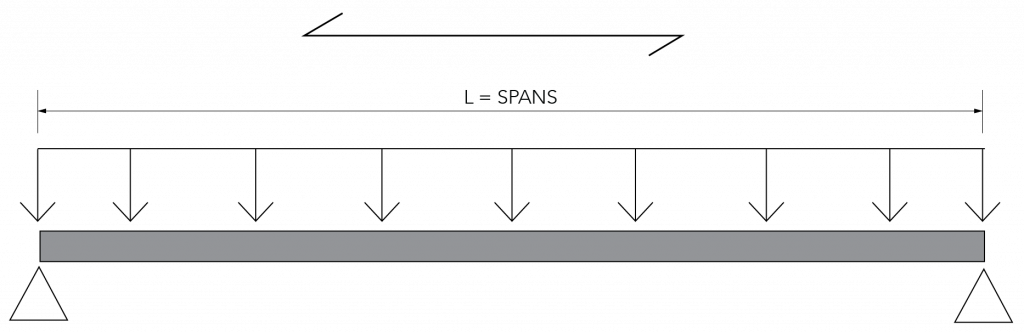

KF40® 3-Pan Formwork/Slab Span Tables - Simple Span

Single Slab Span (L) on Steel support: Formwork deflection limits L/130

| Slab Depth (mm) | 0.75 BMT Number of props per span | 1.0 BMT Number of props per span |

||||

| 0 | 1 | 2 | 0 | 1 | 2 | |

| 90 | 2250 | [5900] | [8250] | 2450 | [6450] | [9000] |

| 100 | 2150 | [5700] | [8000] | 2350 | [6250] | [8700] |

| 110 | 2100 | [5550] | [7750] | 2300 | [6100] | [8500] |

| 120 | 2050 | [5400] | [7550] | 2250 | [5950] | [8250] |

| 130 | 2000 | [5300] | [7350] | 2150 | [5800] | [8050] |

| 140 | 1950 | [5150] | [7200] | 2100 | [5650] | [7850] |

| 150 | 1900 | 5000 | [7000] | 2050 | [5550] | [7700] |

| 160 | 1850 | 4900 | [6850] | 2050 | 5450 | [7550] |

| 170 | 1800 | 4800 | [6750] | 2000 | 5300 | [7400] |

| 180 | 1750 | 4700 | [6600] | 1950 | 5200 | [7250] |

| 190 | 1700 | 4650 | 6500 | 1900 | 5150 | [7150] |

| 200 | 1650 | 4550 | 6400 | 1900 | 5050 | 7000 |

| 210 | 1650 | 4450 | 6300 | 1850 | 4950 | 6900 |

| 220 | 1600 | 4400 | 6200 | 1800 | 4900 | 6800 |

| 230 | 1600 | 4300 | 6100 | 1750 | 4850 | 6700 |

| 240 | 1550 | 4250 | 6000 | 1750 | 4800 | 6600 |

| 250 | 1550 | 4200 | 5950 | 1700 | 4700 | 6550 |

Note:

Brackets indicate Span/Depth ratio greater than 35 for single spans and 40 for double spans

Single Slab Span (L) on Steel support: Formwork deflection limits L/240

| Slab Depth (mm) | 0.75 BMT Number of props per span | 1.0 BMT Number of props per span |

||||

| 0 | 1 | 2 | 0 | 1 | 2 | |

| 90 | 1850 | [5000] | [6900] | 2050 | [5450] | [7600] |

| 100 | 1750 | [4800] | [6700] | 1950 | [5250] | [7300] |

| 110 | 1700 | [4650] | [6450] | 1900 | [5100] | [7100] |

| 120 | 1650 | [4550] | [6300] | 1800 | [4950] | [6900] |

| 130 | 1600 | 4400 | [6100] | 1750 | [4850] | [6700] |

| 140 | 1550 | 4300 | [5950] | 1700 | 4700 | [6550] |

| 150 | 1500 | 4200 | [5800] | 1650 | 4600 | [6400] |

| 160 | 1450 | 4100 | [5700] | 1650 | 4500 | [6250] |

| 170 | 1400 | 4000 | 5550 | 1600 | 4400 | [6100] |

| 180 | 1400 | 3950 | 5500 | 1550 | 4300 | 6000 |

| 190 | 1350 | 3850 | 5400 | 1500 | 4250 | 5900 |

| 200 | 1300 | 3800 | 5300 | 1500 | 4150 | 5800 |

| 210 | 1300 | 3750 | 5200 | 1450 | 4100 | 5700 |

| 220 | 1250 | 3700 | 5100 | 1400 | 4050 | 5600 |

| 230 | 1250 | 3600 | 5050 | 1400 | 4000 | 5500 |

| 240 | 1250 | 3550 | 4950 | 1350 | 3900 | 5450 |

| 250 | 1200 | 3500 | 4850 | 1350 | 3850 | 5400 |

Note:

Brackets indicate Span/Depth ratio greater than 35 for single spans and 40 for double spans

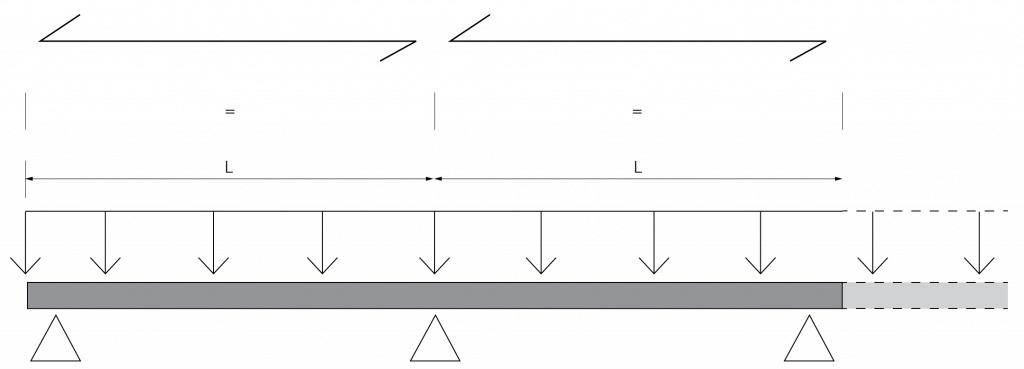

KF40® 3-Pan Formwork/Slab Span Tables - Continuous Spans

Continuous-Two or more Spans (L) on steel support: Formwork deflection limits L/130

| Slab Depth (mm) | 0.75 BMT Number of props per span | 1.0 BMT Number of props per span |

||||

| 0 | 1 | 2 | 0 | 1 | 2 | |

| 90 | 2950 | [5600] | [8400] | 3200 | [6150] | [9150] |

| 100 | 2850 | [5450] | [8100] | 3100 | [5950] | [8850] |

| 110 | 2750 | [5250] | [7850] | 3050 | [5750] | [8600] |

| 120 | 2700 | [5100] | [7650] | 2950 | [5600] | [8400] |

| 130 | 2600 | 5000 | [7450] | 2900 | [5500] | [8200] |

| 140 | 2550 | 4850 | [7300] | 2800 | 5350 | [8000] |

| 150 | 2500 | 4750 | [7150] | 2750 | 5250 | [7800] |

| 160 | 2450 | 4650 | [7000] | 2700 | 5100 | [7650] |

| 170 | 2400 | 4600 | [6850] | 2650 | 5000 | [7500] |

| 180 | 2350 | 4500 | 6750 | 2600 | 4950 | [7350] |

| 190 | 2300 | 4400 | 6600 | 2550 | 4850 | 7250 |

| 200 | 2250 | 4350 | 6500 | 2500 | 4750 | 7150 |

| 210 | 2200 | 4250 | 6400 | 2450 | 4700 | 7000 |

| 220 | 2200 | 4200 | 6300 | 2450 | 4600 | 6900 |

| 230 | 2150 | 4150 | 6200 | 2400 | 4550 | 6800 |

| 240 | 2100 | 4100 | 6100 | 2350 | 4500 | 6700 |

| 250 | 2100 | 4050 | 6050 | 2350 | 4450 | 6650 |

Note:

Brackets indicate Span/Depth ratio greater than 35 for single spans and 40 for double spans

Temporary Propping Tables Notes:

- The tables above denote maximum allowable centreline to centreline span in millimetres between permanent supports after temporary propping is removed.

- The practical limit for span to slab depth ratio is considered to be 35 for single span slabs, or 40 for continuous slabs. Values above these limits have been listed in brackets "[ ]". The use of the results in brackets must be confirmed with the structural engineer or a Fielders representative as the long term serviceability and composite performance of the resulting concrete slab may not be suitable for the project application.

- Allowance has been made for ponding of wet concrete due to decking deflection, density 2400kg/m3.

- Loading is considered in accordance with AS 1170.0:2002, AS/NZS 2327:2017, AS 3610:1995 with a Stage III construction live load allowance of 1.0kPa in accordance with AS/NZS 2327:2017 Appendix A.

- The requirements for Stage II & IV material staking loads in accordance with AS/NZS 2327:2017 Appendix A are assumed to be zero.

- It is recommended that an experienced structural engineer design the composite slab to ensure sufficient capacity to meet strength and long term deflection requirements.

- A span/130 deflection limit will result in a noticable sag in the soffit and should only be adopted when the soffit will not be exposed.

- These tables are based upon effective section properties of the sheeting calculated in accordance to AS 4600:2005.

- Care must be exercised when placing concrete to avoid mounding.

- Wide ply strips, of 300mm wide, shall be provided to prevent any concentrated loads being applied to the sheeting, particularly for exposed soffits, to avoid direct point loading of the sheet overlap ribs and unsupported edges of the sheeting.

- When using the table for two or more spans the adjacent spans should not differ in length by more than 5%.

A maximum sheet length of 12m has been considered. - A minimum bearing width on the permanent support has been considered to be 50mm.

- Fielders recommend a gauge of 1.00 mm BMT for exposed soffits in propped applications to avoid creasing of steel decking. Please contact your local KingFlor® representative for further information.

Continuous-Two or more Spans (L) on steel support: Formwork deflection limits L/240

| Slab Depth (mm) | 0.75 BMT Number of props per span | 1.0 BMT Number of props per span |

||||

| 0 | 1 | 2 | 0 | 1 | 2 | |

| 90 | 2500 | [4700] | [7050] | 2700 | [5150] | [7700] |

| 100 | 2400 | [4550] | [6800] | 2600 | [4950] | [7450] |

| 110 | 2300 | 4400 | [6600] | 2550 | [4800] | [7200] |

| 120 | 2250 | 4250 | [6400] | 2450 | 4700 | [7000] |

| 130 | 2200 | 4150 | [6200] | 2400 | 4550 | [6800] |

| 140 | 2150 | 4050 | [6050] | 2350 | 4450 | [6650] |

| 150 | 2100 | 3950 | 5900 | 2300 | 4350 | [6500] |

| 160 | 2050 | 3850 | 5800 | 2250 | 4250 | 6350 |

| 170 | 2000 | 3800 | 5650 | 2200 | 4150 | 6200 |

| 180 | 1950 | 3700 | 5550 | 2150 | 4050 | 6100 |

| 190 | 1900 | 3650 | 5450 | 2100 | 4000 | 6000 |

| 200 | 1900 | 3600 | 5350 | 2050 | 3950 | 5900 |

| 210 | 1850 | 3550 | 5300 | 2050 | 3850 | 5800 |

| 220 | 1850 | 3450 | 5200 | 2000 | 3800 | 5700 |

| 230 | 1800 | 3400 | 5100 | 1950 | 3750 | 5600 |

| 240 | 1750 | 3350 | 5050 | 1950 | 3700 | 5550 |

| 250 | 1750 | 3300 | 4950 | 1900 | 3650 | 5450 |

Note:

Brackets indicate Span/Depth ratio greater than 35 for single spans and 40 for double spans

Temporary Propping Tables Notes:

- The tables above denote maximum allowable centreline to centreline span in millimetres between permanent supports after temporary propping is removed.

- The practical limit for span to slab depth ratio is considered to be 35 for single span slabs, or 40 for continuous slabs. Values above these limits have been listed in brackets "[ ]". The use of the results in brackets must be confirmed with the structural engineer or a Fielders representative as the long term serviceability and composite performance of the resulting concrete slab may not be suitable for the project application.

- Allowance has been made for ponding of wet concrete due to decking deflection, density 2400kg/m3.

- Loading is considered in accordance with AS 1170.0:2002, AS/NZS 2327:2017, AS 3610:1995 with a Stage III construction live load allowance of 1.0kPa in accordance with AS/NZS 2327:2017 Appendix A.

- The requirements for Stage II & IV material staking loads in accordance with AS/NZS 2327:2017 Appendix A are assumed to be zero.

- It is recommended that an experienced structural engineer design the composite slab to ensure sufficient capacity to meet strength and long term deflection requirements.

- A span/130 deflection limit will result in a noticable sag in the soffit and should only be adopted when the soffit will not be exposed.

- These tables are based upon effective section properties of the sheeting calculated in accordance to AS 4600:2005.

- Care must be exercised when placing concrete to avoid mounding.

- Wide ply strips, of 300mm wide, shall be provided to prevent any concentrated loads being applied to the sheeting, particularly for exposed soffits, to avoid direct point loading of the sheet overlap ribs and unsupported edges of the sheeting.

- When using the table for two or more spans the adjacent spans should not differ in length by more than 5%.

A maximum sheet length of 12m has been considered. - A minimum bearing width on the permanent support has been considered to be 50mm.

- Fielders recommend a gauge of 1.00 mm BMT for exposed soffits in propped applications to avoid creasing of steel decking. Please contact your local KingFlor® representative for further information.

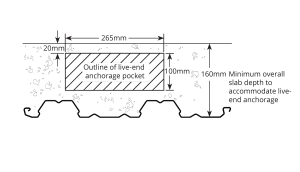

KF40® Pre-stressed / Post-tensioned Slabs

KF40® can be adopted as permanent formwork and composite reinforcement in the design and construction of post-tensioned composite slabs.

The shallow overall depth of the KF40® profile allows post-tensioning tendons to be draped in the spanning and transverse directions of the slab without clashes.

The primary post-tensioning tendons draped parallel to the spanning direction of the KF40® slab are located centrally between ribs at the cover specified in Tables 2A, 2B and 2C to achieve the required FRL.

The minimum recommended post-tensioned slab thickness is 160mm to allow tendons to be draped and pre-stressing anchorages to fit within the slab depth without causing horizontal splitting.

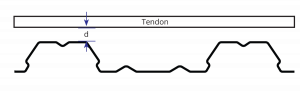

Figure KF 40 003

Fitting a Typical Live-End Anchorage in a Composite Slab Incorporating KF40®

Note: Anti-bursting reinforcement can be supported off lap ribs, which ideally are only 20mm high and allow concrete aggregate to pass around the reinforcing bars as necessary.

Locating Longitudinal Tendons

The location of the post-tension tendon for KF40® slabs are determined in order to not exceed the limiting steel temperatures of 450°C (simply supported), 520°C (flat slab) and 650°C (continuous) to ensure consistency with the current version of AS 3600:2009.

For the case of tendons having parallel orientation to the deck it is assumed that the tendon is located centrally between two KF40® ribs. This gives a distance from the centreline of the rib to the edge of the tendon of 85mm. The required distances from the heated soffit to the bottom of the tendon have been determined using TASEF-2 analyses previously undertaken for KF40®.

The slab thickness has been assumed to be 160mm but the results can be considered to be applicable to the range of practical post-tensioned concrete slabs.

Figure KF 40 004

Distances to the Prestressing Tendon.

Table 2A: Minimum Distance (D) to Underside of Tendon from Soffit (S = 45mm)

| FRL | Simply Supported (mm) | Continuous (mm) | Flat Slabs (mm) |

| 120 | 47 | 25 | 36 |

| 180 | 67 | 35 | 55 |

| 240 | 83 | 47 | 70 |

Table 2B: Minimum Distance (D) to Underside of Tendon from Soffit (S = 70mm)

| FRL | Simply Supported (mm) | Continuous (mm) | Flat Slabs (mm) |

| 120 | 49 | 25 | 38 |

| 180 | 69 | 37 | 58 |

| 240 | 84 | 49 | 73 |

Table 2C: Minimum Distance (D) to Underside of Tendon from Soffit (S = 90mm)

| FRL | Simply Supported (mm) | Continuous (mm) | Flat Slabs (mm) |

| 120 | 53 | 25 | 42 |

| 180 | 71 | 38 | 60 |

| 240 | 85 | 50 | 75 |

Installing KF40®

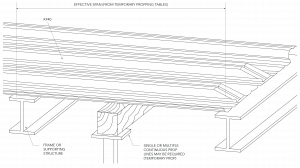

Temporary Propping

If temporary propping is required (refer to the temporary propping tables), props should be placed at the correct centres prior to laying the KF40® sheets. Generally, timber or steel bearers with a minimum dimension of 75mm x 75mm are used on vertical props. The props should be installed so as to prevent settlement during loading by wet concrete and other construction loads.

300mm wide ply strips to be positioned above the header bearers to assist in dispersing the load and minimise any local deformation of the decking due to the headers.

Temporary props should only be removed after the slab has reached sufficient strength (at least 75% of the specified 28 day strength). The full design load may only be applied once the slab has achieved 28-day strength.

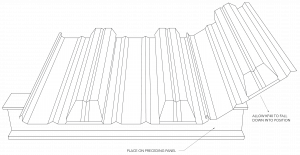

Laying KF40®

- Place the KF40® sheet over the supports ensuring a minimum end bearing of 50mm. If supporting on a brick or masonry wall, provide a separating strip such as malthoid.

- Engage subsequent sheets of KF40® by locking the larger female rib over the male rib as shown in the diagram below. No crimping is required in this situation.

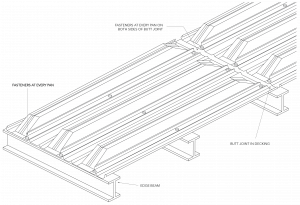

SquashCutTM/Band Beam Detail

Fastener Locations

The decking must be positively fixed to the supporting structure in order to avoid movement and excessive deflection during the pouring of concrete.

When fixing to a steel support structure, shot fired pins or self- drilling/tapping fasteners should be used. Provide one fastener in each pan at every support.

In the case of other support systems, such as brickwork, block work and concrete, the KF40® sheets must be temporarily held in place against wind and other effects until the concrete is poured.

Edge-form

Galvanised steel edge-forms can be used for the retention of wet concrete to the correct level at the decked floor perimeters. KF40® edge-form is usually shot-fired to the steel support structure or to the KF40® deck and the top of the edge-form is connected back to the decking with restraint straps at approximately 600mm centres using either pop-rivets or self-drilling screws.

Reinforcement

Place all reinforcement in strict accordance with the structural engineer’s drawings and specification.

Concrete Placement

The specified grade of concrete and any chemical admixtures must be in strict accordance with AS 3600:2009 and the structural engineer’s drawings and specification. The deck must be clear of any excess dirt, grease or debris as this inhibits bonding between the deck and concrete.

Ensure that concrete is applied evenly over the decking surface, as mounding of the wet concrete will cause excessive local loading.