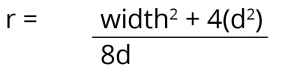

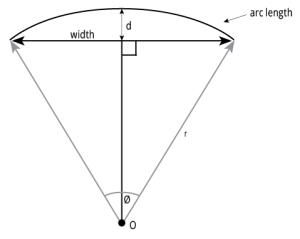

Calculations

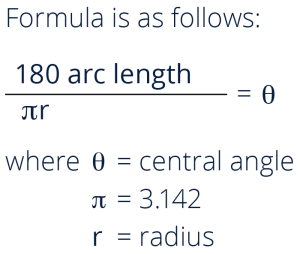

To calculate rise when radius, r and arc length are known, first determine the central angle as below:

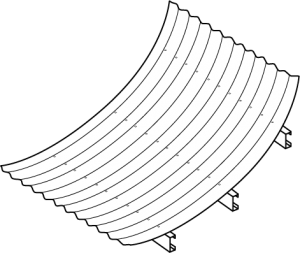

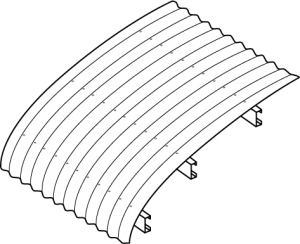

Spring Curving of Concealed Fix Deck

Fielders’ HiKlip® 630, KingKlip 700® can successfully be sprung curved within certain parameters. The performance of spring curved KingKlip® for resistance to wind loads is shown in Table DD CSD CSC 001 and Table DD CSD CSC 002. However there are factors to take into account other than the ‘unzipping’ of the deck from the clip. Aesthetics often determine the suitability of the use of a roofing deck and consequently there are limiting considerations, given the propensity of a wide pan concealed fix deck to ‘oil can’ or facet. (Click for further information about oil canning)

Wide pan concealed fix decks will not spring curve down to the radii that corrugated and close pitch trapezoidal screw fix decks will achieve.

Furthermore, it is impractical to table the ability of Fielders’ concealed fix profiles to spring curve given there are numerous variables that affect their performance, for instance gauge, purlin spacings, wind pressure and the degree of acceptability for oil canning. In general terms, the higher the rib, the more difficult it will be to spring curve successfully. Conversely, a heavier gauge material will improve the roof’s aesthetic performance in this regard.

Fielders’ experienced sales staff will be able to provide feedback in relation to your specific project.

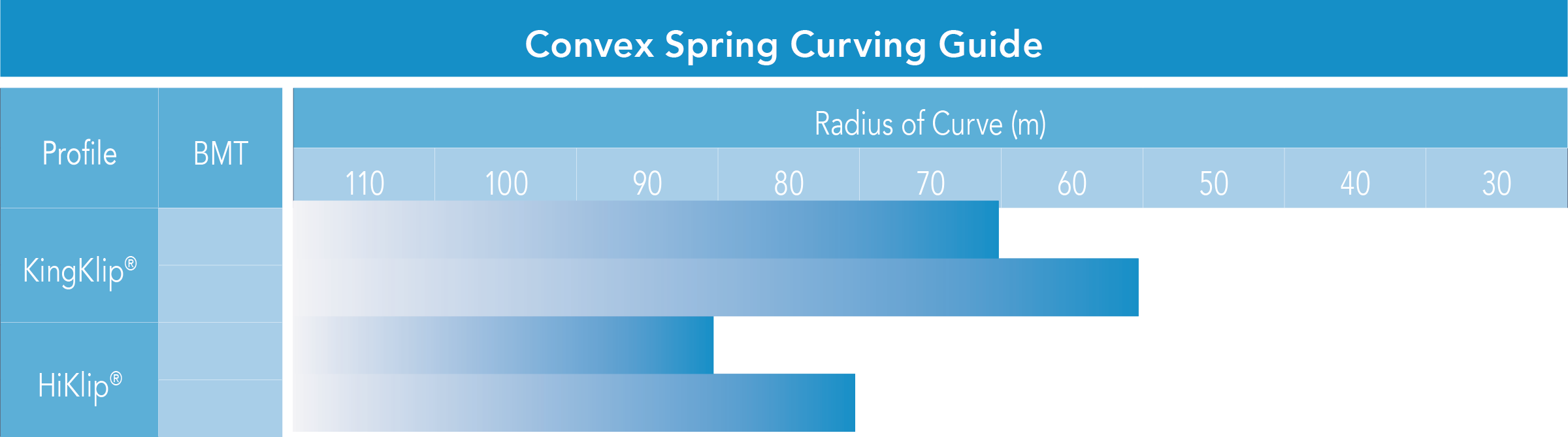

Figure DD CDS 003 gives indicative performance of Fielders® concealed fix profiles when spring fixed. The data provided is typical only and varies subject to limit state wind pressure, building height, purlin spacings and other factors. Typically the tighter the radius, the greater propensity for oil canning or faceting to occur (although the deck will not ‘unzip’).

Convex Spring Curved KingKlip 700® Wind Load Capacity

Limit State Design (kPa) Non - Cyclonic. Fixed with Mark II Clips

Concave Spring Curved KingKlip 700® Wind Load Capacity

Limit State Design (kPa) Non - Cyclonic. Fixed with Mark II Clips

| Span (mm) | Radius of curvature (m) | |||||

| Flat | 90 | 80 | 70 | 60 | 50 | |

| 1200 | 2.19 | 1.96 | 1.94 | 1.90 | 61 | 1.79 |

| 1500 | 1.92 | 1.82 | 1.80 | 1.77 | 62 | 1.68 |

| 1800 | 1.72 | 1.66 | 1.65 | 1.63 | 63 | 1.57 |

| 2100 | 1.57 | 1.54 | 1.53 | 1.51 | 64 | 1.47 |

| 2400 | 1.46 | 1.45 | 1.44 | 1.43 | 65 | 1.40 |

| 2700 | 1.28 | 1.28 | 1.28 | 1.27 | 66 | 1.24 |

Curvatures below 70m are achievable, but not recommended, due to significant thermally induced noise potential

| Span (mm) | Radius of curvature (m) | |||||

| Flat | 90 | 80 | 70 | 60 | 50 | |

| 1200 | 3.04 | 2.68 | 2.64 | 2.58 | 2.50 | 2.39 |

| 1500 | 2.85 | 2.66 | 2.62 | 2.58 | 2.51 | 2.43 |

| 1800 | 2.62 | 2.50 | 2.48 | 2.45 | 2.41 | 2.36 |

| 2100 | 2.39 | 2.32 | 2.30 | 2.28 | 2.26 | 2.22 |

| 2400 | 2.05 | 2.01 | 2.00 | 1.98 | 1.96 | 1.93 |

| 2700 | 1.73 | 1.71 | 1.70 | 1.68 | 1.66 | 1.64 |

Curvatures below 70m are achievable, but not recommended, due to significant thermally induced noise potential

Notes:

- These capacity figures relate to the penultimate clip of a continuous sheet to guard against an ‘unzipping’ failure.

- Capacities in bold show max load capacity / purlin spacing for each radius.

- Faceting will be most significant with small radii, thin sheeting & large purlin spacing.

- Oil canning will be more significant with thin sheet & small radius curving.

- It is assumed that all purlins are sufficiently rigid to maintain a curved ‘profile’ along the span.

- Contact Fielders® for project specific advice on aesthetic performance in sprung curve applications.Tables DD CSD CSC 001 and DD CSD CSC 002 are calculated from analytical performance based upon:

1. Sheet stiffness determined from single span load & deflection tests.

2. Sheets are continuous over five equal spans.

3. Purlin reactions are computed to achieve a circular profile.

4. Uplift capacity at clips is reduced by the tension force to form then curved profile.

Spring Curving of Pierce Fix Decks

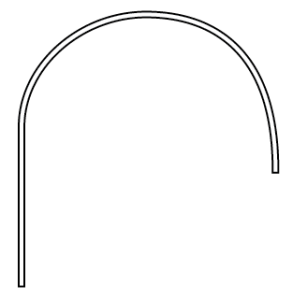

Convex Spring Curving

COLORBOND® & ZINCALUME® steel’s versatile properties allow the roofer to curve straight sheeting on-site to the radii shown in the tables to the right.Side laps should be sealed with recommended sealants over the crest of the arch where the slope is less than recommended minimum for that sheet profile. If end laps are necessary, they should not be located at or near the crest of the arch and each sheet length should span at least three purlin spacings. The top face of all purlins should accurately follow, and be tangential to, the arch curvature. Each alternate sheet should be laid from opposite sides of the roof. It should be noted that very slight crease marks may appear in the trays or valleys over the supports when curved sheeting is subjected to foot traffic. These crease marks do not affect the integrity of the sheets.

| Spanform™ | S-Rib™ Corrugated | ||||

| 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.60 BMT | |

| Minimum Radius (m) | 20 | 20 | 12 | 10 | 9 |

| Purlin Spacing at Minimum Radius (mm) | 1400 | 1200 | 800 | 1000 | 900 |

| Maximum Radius (m) | 60 | 60 | 35 | 35 | 35 |

Note:

Maximum recommended radius to provide sufficient drainage near crest of curvature.

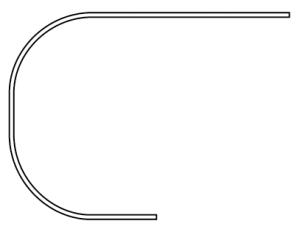

Concave Spring Curving

Roof slope at the lower end of the sheeting must not be less than the minimum pitch for the selected roofing profile.

| Spanform™ | TL-5™ | S-Rib™ Corrugated | |||||

| 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.60 BMT | |

| Minimum Radius (m) | 18 | 20 | 20 | 22 | 10 | 10 | 8 |

| Purlin Spacing at Minimum Radius (mm) | 1200 | 1400 | 1200 | 1000 | 800 | 1000 | 800 |

Note:

Maximum recommended radius to provide sufficient drainage near crest of curvature.

Crank Curving

Fielders® brings a new dimension to commercial and industrial roofing with versatile crank curved decking available in TL-5, Spanform® and KingKlip 700® profiles.

The Advantages of Crank Curving

- Smoother flow of wind over eaves, meaning less chance of sheet ends lifting

- Continuous pieces reduce cost

- Curved edges can eliminate debris collecting in gutters and fascia purlins because rain can simply run straight downwards and be collected in spoon drains

- It is easier to clean a spoon drain than to clear the corrosion causing debris collected in eaves guttering

- The ability to curve from roofing straight down into vertical sheets can eliminate the need for bird or vermin-proofing of regular eaves

- Minimum radius for crank curving is 750mm for TL-5 and 900mm for KingKlip® and Spanform

Notes:

There are a number of essential prerequisites for ordering a crank curved project:

1. Either the exact radius or an accurate full size template must be supplied by the customer

2. A set of detailed, fully dimensioned drawings also need to be submitted

3. The customer must allow for two additional sheets over and above the estimated amount to be used as test sheets

Minimum Radii for Smooth Curving KingKlip 700®

| BMT (mm) | Grade | Minimum Radius (m) | Maximum Purlin Spacing (mm)* |

| 0.42 | G550 | 20.00 | 1500 |

| 0.48 | G550 | 20.00 | 1800 |

| 0.50 | G550 ▲■ | 18.00 | 1800 |

| 0.55 | G300 ▲■ | 15.00 | 1800 |

| 0.70 | G220 ▲■ | 12.00 | 1800 |

Notes:

This table does not provide definitive values and should not be used as a basis for design without consulting Fielders® technical staff

*After which faceting occurs. These limits do not reflect wind load capacity limits.

▲Subject to availability and special pricing.

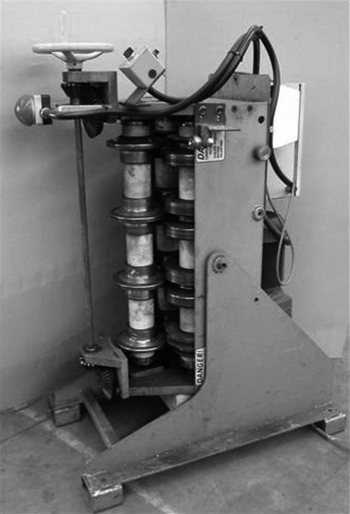

Smooth Curving of Concealed Fix Decks - KingKlip®

Smooth curving is an option unique to Fielders®. All profiles have limitations as to the minimum radius to which they can be spring fixed. Crank curving is available in a number of profiles however it is not aesthetically acceptable on some projects. Profiles such as Corrugated and others may be spring curved or fixed to relatively tight radii but they are all pierce fixed decks and SAA HB 39 – 1997 section 7.17.3 states that all side laps should be sealed with a recommended sealant where the pitch of the roof is less than the recommended pitch for the given profile. Whilst this does provide a ‘method’ of fixing, it is not deemed to be the most desirable solution in that the watertightness of the roof is largely dependent on the silicone seal.

KingKlip 700® is able to be smooth curved by Fielders® state of the art purpose built machinery achieving smooth curves to much tighter radii than can be achieved by spring curving. KingKlip®, being a concealed fix product, provides a far more secure barrier to the ingress of water for a curved roof than a screw fixed product. The minimum achievable pitches are determined by the gauge and grade of steel used, refer to Table DD CSD MR 001 to the left.

Ordering Smooth Curved Roofs

Fielders® need to view detailed drawings to determine the following:

- The suitability of the roof for smooth curving and what material would achieve the best result

- Whether the curving needs to take place on site or in the factory

- Calculation of costs in order to prepare a detailed quotation

- Ascertain whether it is necessary to visit the site to ensure that there is sufficient area available on site if an on-site curve is required. This will be particularly relevant to when long length sheets are required

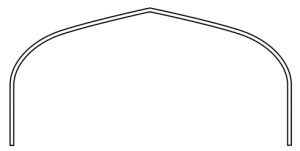

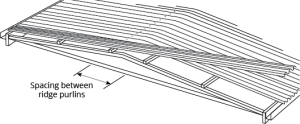

Spring Curving of Ridges

On lower pitch roofing the process of spring-curved ridges eliminates the need for ridge capping. Full length sheeting can be laid from eave to eave and spring curved between the ridge purlins. This process eliminates the possibilities of leakage caused by a break in the sheeting at the ridge, providing a neat and cheap alternative to ridge capping.

- As a result of this process some oil canning, purlin lines, or puckering of laps can occur in the ridge curve

- Side laps should be sealed for the length of the curvature

- Each sheet should be first fastened to one side of the roof and then pulled down

to the other side of the gable

Figure DD CDS SCR 004

Minimum Spacing of Ridge Purlins for Spring Curving (mm)

| Roof Pitch | KingKlip 700® | Spanform™ | TL-5™ | S-Rib Corrugated | |||||

| 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.42 BMT | 0.48 BMT | 0.60 BMT | |

| 2 ° (1 in 30) | 1900 | 2700 | N/A | N/A | 1500 | 1600 | N/A | N/A | N/A |

| 3 ° (1 in 20) | 2000 | 2800 | 1500 | 1600 | 1600 | 1700 | N/A | N/A | N/A |

| 4 ° (1 in 15) | - | - | 1600 | 1700 | - | 1800 | N/A | N/A | N/A |

| 5 ° (1 in 12) | - | - | - | 1800 | - | - | 1200 | 1300 | 1200 |

| 6 ° (1 in 10) | - | - | - | - | - | - | - | 1400 | 1300 |

| 7 ° (1 in 8) | - | - | - | - | - | - | - | - | 1400 |

Notes:

All other purlins spacings as per product specifications.

N/A - not applicable