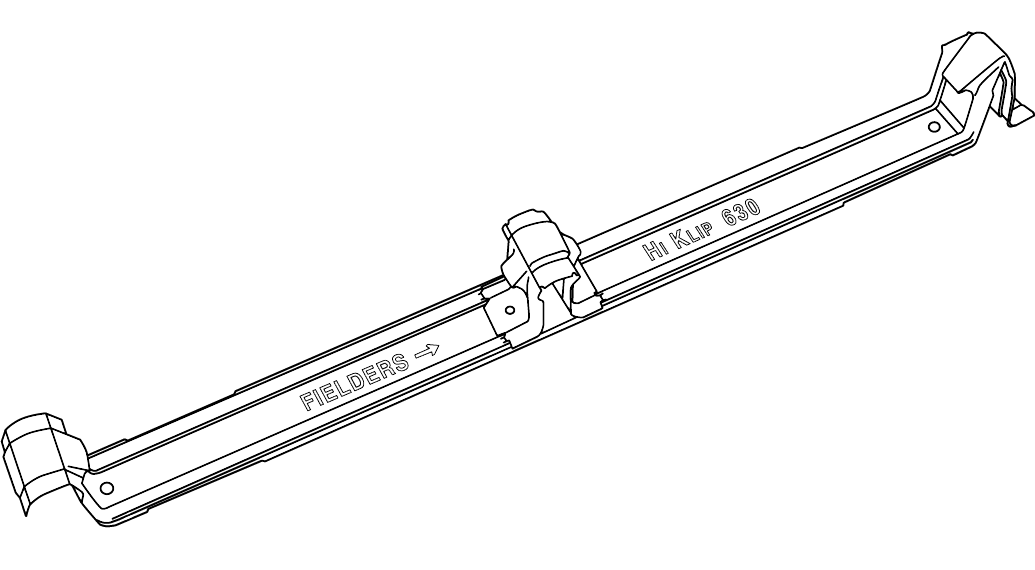

About HiKlip® 630

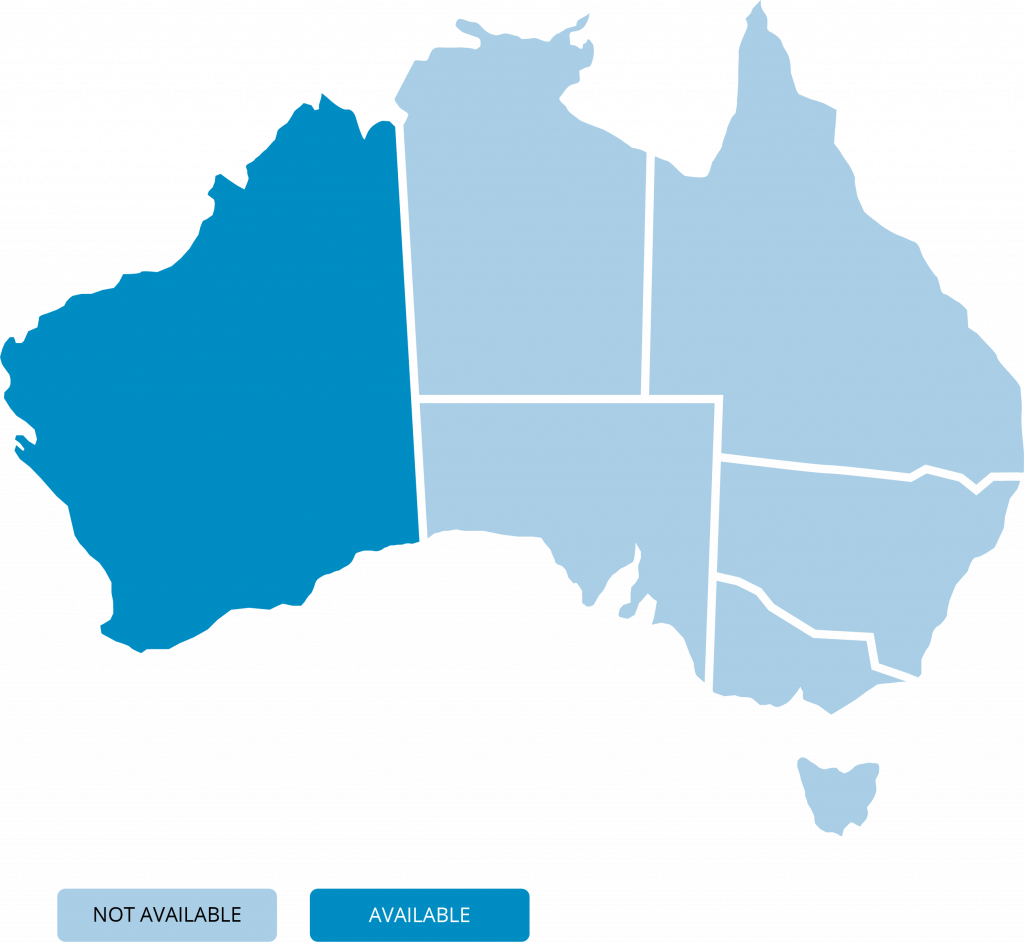

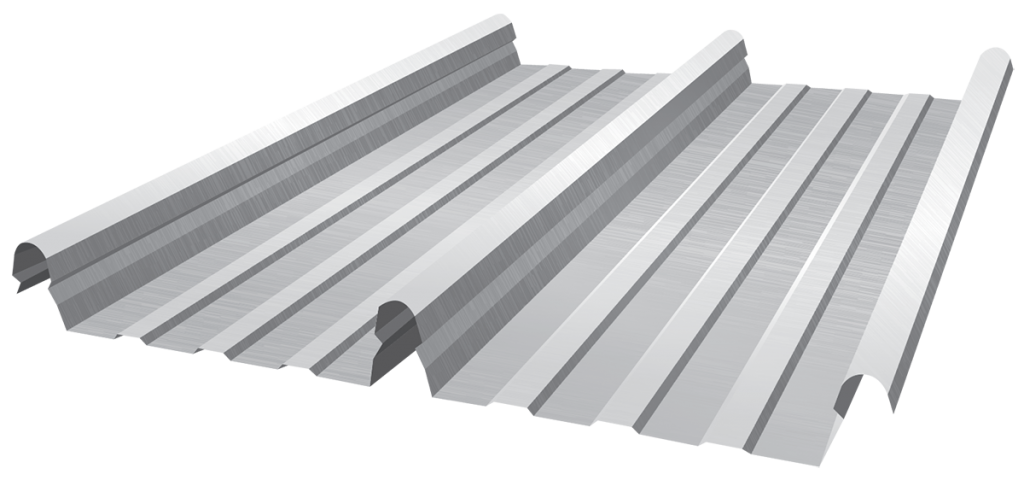

High and mighty, HiKlip® 630 is the largest water-carrying concealed-fixed roofing in Australia. Purposely built to survive the strongest stormy weather for major commercial, industrial and domestic projects. HiKlip® 630 ensures ultimate protection, strength and durability, with large span capabilities that deliver on value, ensuring fewer purlins and lower costs.

Stylish as well as strong, HiKlip® 630 has been described by architects as striking, imposing and bold. Available in a range of COLORBOND® steel light and heavy gauge colours, HiKlip® 630 is truly aesthetically pleasing. HiKlip® 630 can be produced with the Fielders® Mobile Mill, available to be made onsite and in real time to suit the required length.

Material Specifications

| Property | Notes | |||

| Base Metal Thickness (mm) | 0.42 | 0.48 | BMT | |

| Total Coated Thickness (mm) | 0.47* | 0.53* | TCT | |

| Mass / Unit Length | ZINCALUME® | 3.26 | 3.70 | kg/m |

| COLORBOND® | 3.32* | 3.76* | ||

| Mass / Unit Area | ZINCALUME® | 5.17 | 5.87 | kg/m2 |

| COLORBOND® | 5.49* | 6.23* | ||

| 2nd moment of area about principal axis (103 mm4) | Ix | 212 | 242 | |

| Iy | 16650 | 19030 | ||

| Section modulus about principal axis (103 mm3) | Zx | 5 | 5 | |

| Zy | 49 | 55 | ||

| Warping Constant (109 mm6) | Iw | 10 | 11 | |

| Torsion Constant (mm4) | J | 23 | 35 | |

| Minimum Yield Strength | G550 | Base Steel Designation | ||

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME®) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

||

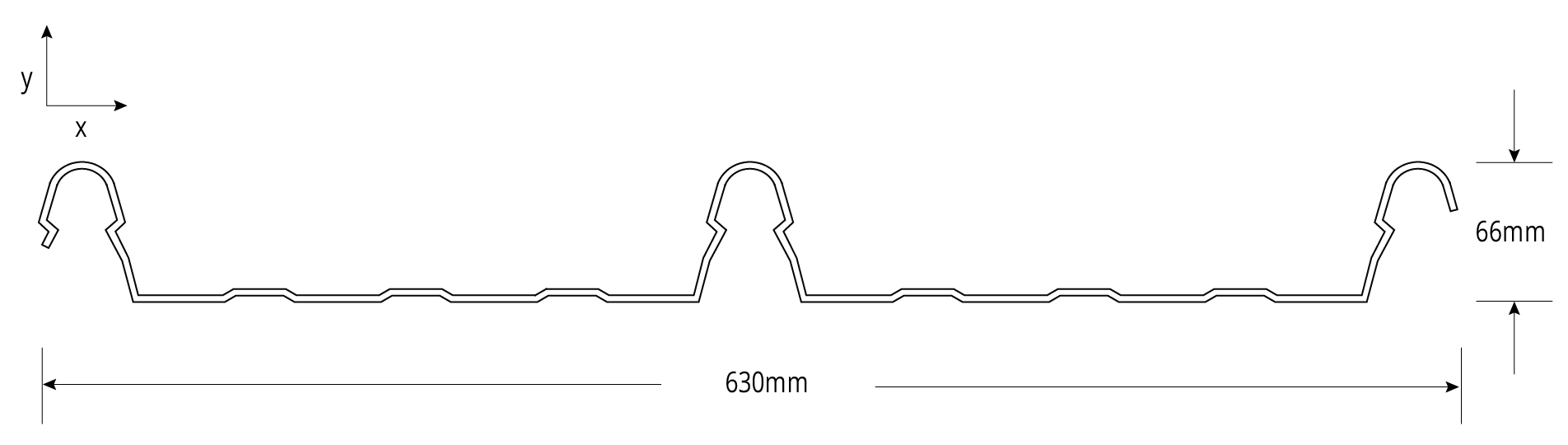

| Coverage (mm) | 630 | |||

| Tolerance | Sheet Length ±7mm Cover Width ±4mm | |||

| Thermal Expansion | 2.9mm average per 5m at 50°C change | |||

- HiKlip® 630 is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

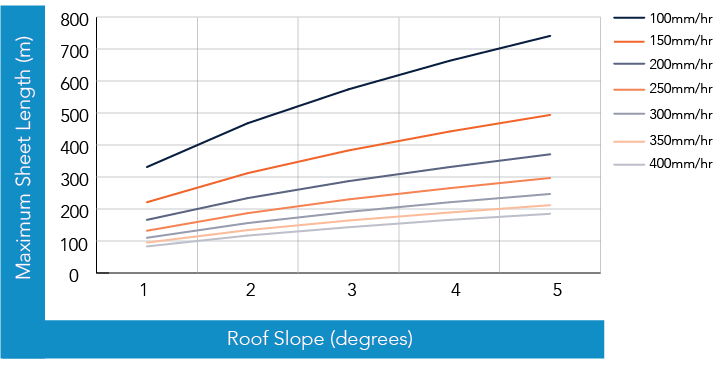

Rainfall Capacity

For further information, please refer to sections "Rainfall Intensity" and "Water Carrying Capacity and Rainwater Run-Off".

Figure HK RC NC 001

Non-Cyclonic Load Span Tables

The design pressures and allowable spans have been determined from tests carried out in accordance with the following Australian Standards: AS 1562.1:1992, “Design and installation of sheet roof and wall cladding – Metal” and AS 4040:1992, “Methods of testing sheet roof and wall cladding”. All values are applicable for fixing into a minimum steel support thickness of 1.5mm.

Wind Pressure Capacities: Non-Cyclonic: 0.42mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 1200 | 4.50 | 8.40 | 5.00 | 8.60 | 6.00 | 11.50 |

| 1500 | 3.70 | 5.50 | 4.10 | 6.75 | 5.00 | 8.60 |

| 1800 | 3.00 | 4.00 | 3.35 | 5.30 | 4.00 | 6.75 |

| 2100 | 2.40 | 3.10 | 2.75 | 4.15 | 3.20 | 5.30 |

| 2400 | 1.90 | 2.45 | 2.25 | 3.40 | 2.55 | 4.15 |

| 2700 | 1.50 | 2.00 | 1.85 | 2.80 | 2.05 | 3.40 |

| 3000 | 1.15 | 1.60 | 1.55 | 2.40 | 1.75 | 2.80 |

| 3300 | 0.85 | 1.35 | 1.35 | 2.10 | 1.55 | 2.40 |

| 3600 | 0.65 | 1.15 | 1.15 | 1.80 | 1.35 | 2.10 |

Note:

- Values are based on fixing into steel supports with a minimum thickness of 1.5mm.

- Values in italics are estimates based on trend lines fitted to the test data.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Wind Pressure Capacities: Non-Cyclonic: 0.48mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 1200 | 5.05 | 10.75 | 5.55 | 11.50 | 7.25 | 14.25 |

| 1500 | 4.15 | 7.70 | 4.50 | 8.25 | 5.95 | 11.20 |

| 1800 | 3.35 | 5.60 | 3.70 | 6.10 | 4.95 | 8.60 |

| 2100 | 2.70 | 4.10 | 3.05 | 4.75 | 4.10 | 6.70 |

| 2400 | 2.15 | 3.05 | 2.50 | 3.85 | 3.50 | 5.25 |

| 2700 | 1.70 | 2.35 | 2.05 | 3.25 | 3.00 | 4.20 |

| 3000 | 1.35 | 1.90 | 1.65 | 2.80 | 2.60 | 3.50 |

| 3300 | 1.05 | 1.60 | 1.40 | 2.40 | 2.25 | 3.05 |

| 3600 | 0.84 | 1.45 | 1.15 | 2.10 | 1.95 | 2.85 |

Note:

- Values are based on fixing into steel supports with a minimum thickness of 1.5mm.

- Values in italics are estimates based on trend lines fitted to the test data.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

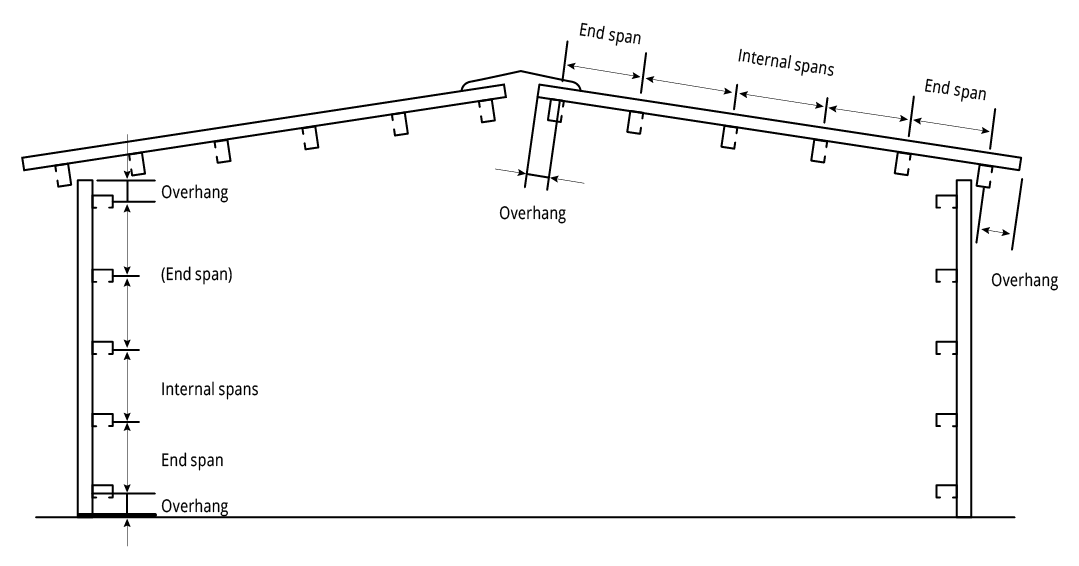

Figure HK NC 002 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Maximum Recommended Roof Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 2 | Terrain Category 3 | ||||

| Single (mm) | End (mm) | Internal (mm) | Single (mm) | End (mm) | Internal (mm) | ||

| A | 0.42 | 2000 | 2200 | 2600 | 2000 | 2200 | 2600 |

| 0.48 | 2400 | 2700 | 3000* | 2400 | 2700 | 3000* | |

| B | 0.42 | 2000 | 2200 | 2600 | 2000 | 2200 | 2600 |

| 0.48 | 2100 | 2400 | 3000* | 2400 | 2700 | 3000* | |

Terrain Category 2

Maximum Roof Height = 10m

External Pressure Coefficient:

Cp,e = -0.65

Internal Pressure Coefficient:

Cp,i = 0.20

Design Wind Pressure:

Pu = 2.25kPa

Ps = 1.93kPa

Local Pressure Factors:

KL = 2.0

Wind Speed:

vu = 50m/s

Table HK RS NC 002 - HiKlip® 630 Non-Cyclonic

Note:

- Maximum roofing spans comply with both strength and serviceability wind pressure requirements.

- Spans shown in italics are limited by foot traffic requirements.

- * Spans in excess of 3000mm available subject to enquiry. Long spans require particular attention to installation practice.

Note:

1. Recommended roof spans are based on foot traffic only.

Maximum Recommended Roof Cladding Spans Based on Foot Traffic

| Base Metal Thickness (mm) | Single (mm) | End (mm) | Internal (mm) |

| 0.42 | 2000 | 2200 | 2600 |

| 0.48 | 2400 | 2700 | 3000* |

Notes:

- * Spans in excess of 3000mm may be available subject to enquiry. Long spans require particular attention to installation practice.

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 2 | Terrain Category 3 | ||||

| Single (mm) | End (mm) | Internal (mm) | Single (mm) | End (mm) | Internal (mm) | ||

| A | 0.42 | 2800 | 3000* | 3000* | 3000* | 3000* | 3000* |

| 0.48 | 3000 | 2450 | 3000* | 3000* | 3000* | 3000* | |

| B | 0.42 | 2150 | 2600 | 3000* | 2650 | 3000* | 3000* |

| 0.48 | 2450 | 2900 | 3000* | 2950 | 3000* | 3000* | |

Terrain Category 2

Maximum Roof Height = 10m

External Pressure Coefficient:

Cp,e = -0.65

Internal Pressure Coefficient:

Cp,i = 0.20

Design Wind Pressure:

Pu = 2.25kPa

Ps = 1.93kPa

Local Pressure Factors:

KL = 2.0

Wind Speed:

vu = 50m/s

Table HK RS NC 001 - HiKlip® 630 Non-Cyclonic

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

- * Spans in excess of 3000mm available subject to enquiry. Wall applications or long spans require particular attention to installation practice.

Insulation

Care needs to be taken when installing insulation with roof sheeting. When insulation thickness up to 50mm are installed the screws detailed in Table HK CF NC 001 may need to be increased depending on the thickness and density of the insulation. When the screw is properly tightened into metal there should be a minimum of three (3) threads protruding past the support being fixed in to. For timber the screw must penetrate the timber as much as the screws detailed in Table HK CF NC 001 do without insulation.

For insulation thicknesses greater than 50mm Fielders® recommend the use of a thermal spacer to help maintain Rw values as well as minimising any bulging in the profile caused by the insulation.

Fasteners - Clip Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

For Non-Cyclonic regions, 3 screws shall be used per clip.

Recommended Fasteners: Concealed-Fixed

| Supports | Recommended Fastener |

| Steel 1.5mm | No. 10 x 25 mm Hexagon head self-drilling screws for metal |

| Timber Hardwood | No.12 x 25mm Hexagon head Type 17 self-drilling screws |

| Timber Softwood | No.12 x 45mm Hexagon head Type 17 self-drilling screws |

Notes:

- Use three (3) fasteners per clip

- Recommended fasteners shown in Table HK RF NC 001 are for construction without insulation

Laying HiKlip® 630

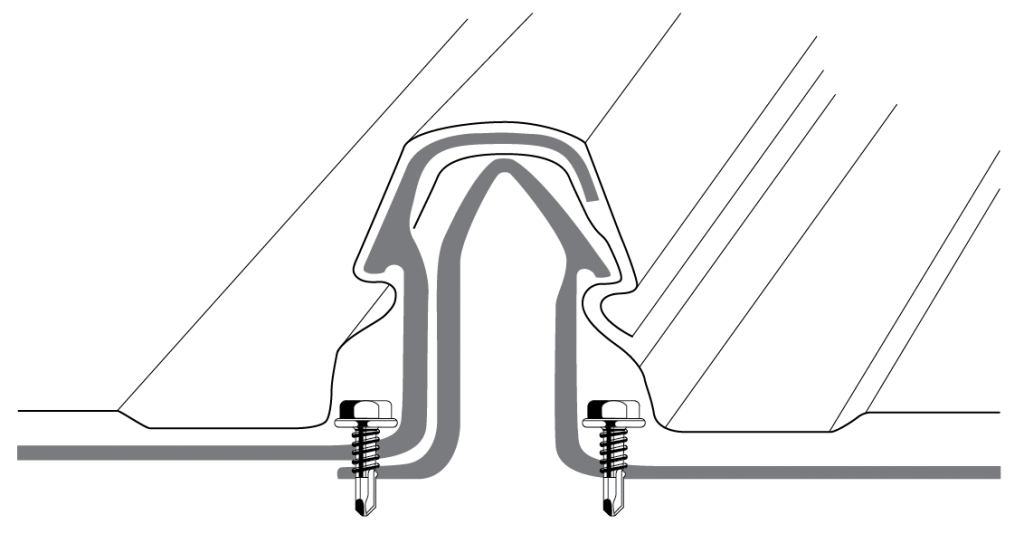

Step 1

Fix the first of the HiKlip® 630 clips perpendicular to the gutter in a straight line using the correct fasteners. Use a string line or the edge of the first sheet to ensure straightness. Care should be taken so that the overlap is facing away from the prevailing weather.

Step 2

Locate the first sheet above the clips ensuring that the overhang into the gutter is correct. Push downwards on the sheet until the decking is secured at every clip. Do not use excessive force.

Step 3

Lap the next HiKlip® 630 clip over the top of the male rib, ensuring that the sheet being laid is parallel to the previous sheet and perpendicular to the gutter line. Fasten this first and fix the remaining two holes as previously done. Fasten all clips in this manner.

Step 4

Lay the next sheet of HiKlip® 630 as previously described. Checks should be carried out periodically to ensure the decking is installed squarely. This can be done by comparing the coverage at the ridge to that at the gutter line or by using a string line. At the end of the purlins, cut the deck and clip to suit.

Step 5

Turn up the HiKlip® 630 pans at the ridge line. On lower pitches the pans should be turned down at the gutter line.

Step 6

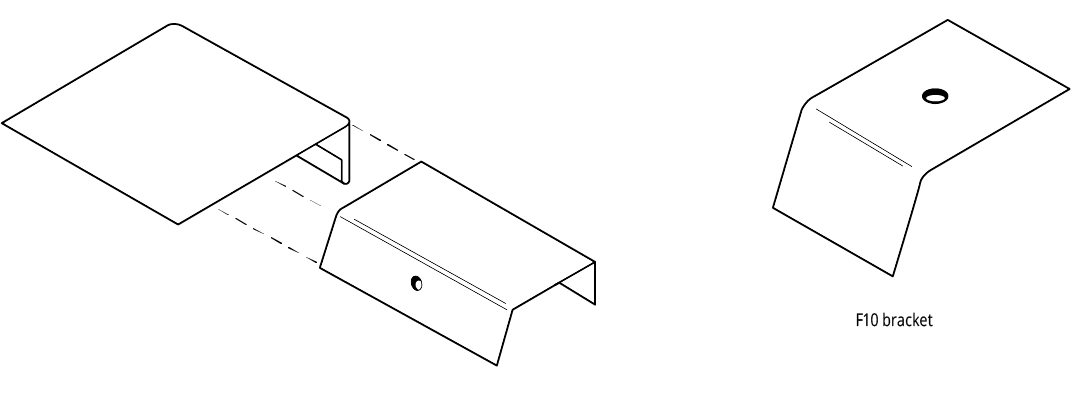

Flash the roof with compatible products using F10 brackets and sliding brackets as necessary to allow for thermal expansion and contraction.

Step 7

Clean the roof daily during construction as per Fielders® maintenance guide, ensuring the removal of all swarf, pop rivets and fasteners.

Concealed Fastening

Unique double-clip action

Only HiKlip® 630 features an over-and-under double clipping action on the side lap for added strength to withstand the strongest winds. And therefore, because the clips and brackets allow the sheet to move with temperature changes, you do not need step/expansion joints.

Further details are available in “Comparative Analysis: Concealed Fix vs. Screw Fix”.

Turning of Roof Sheeting Ends

Refer to section “Flashings, Cappings & Ends of Sheets”.

Designing Without Step Joints

For further information regarding the design of HiKlip® 630 roofs without step joints, please see section "Long Length Roofing Solutions".

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving HiKlip® 630

For details regarding spring curving of HiKlip® 630 sheets, please see section “Curving of Steel Decks”.

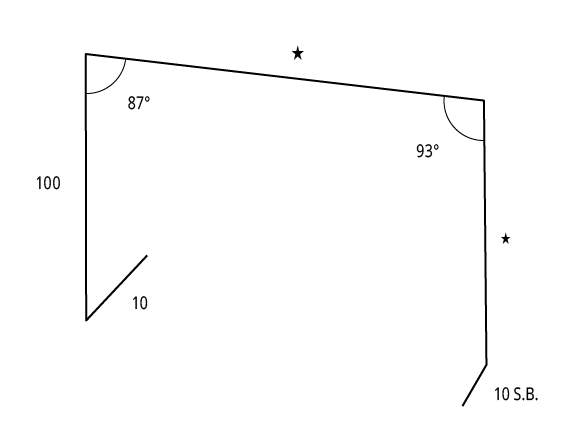

HiKlip 630® Flashings & Details

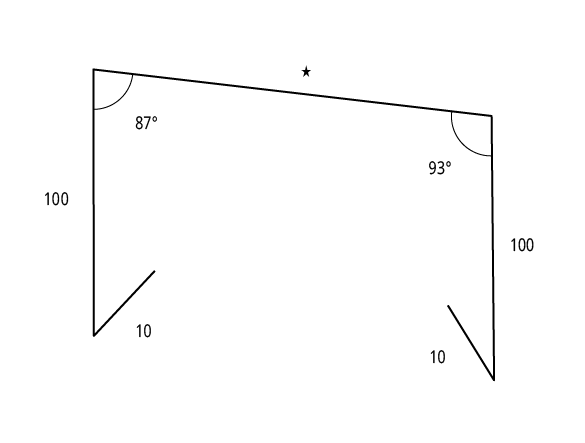

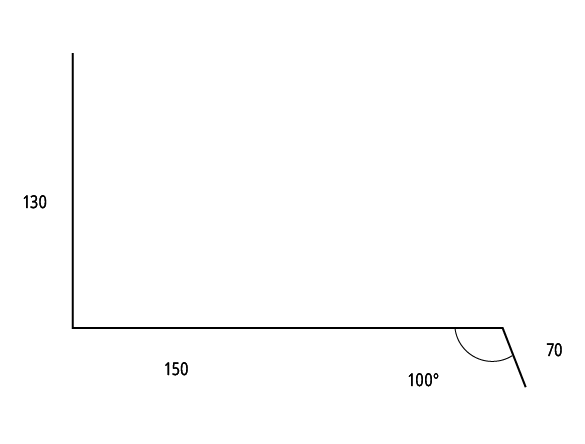

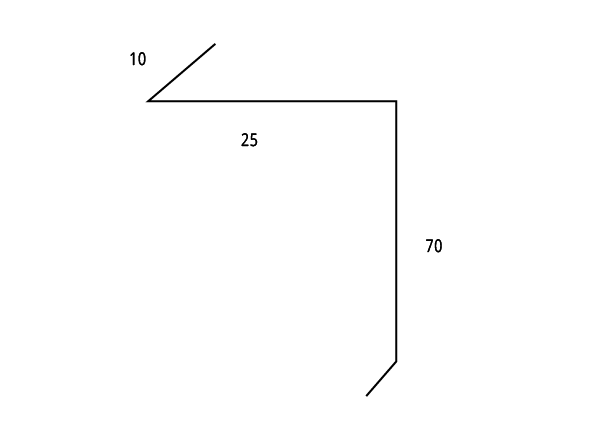

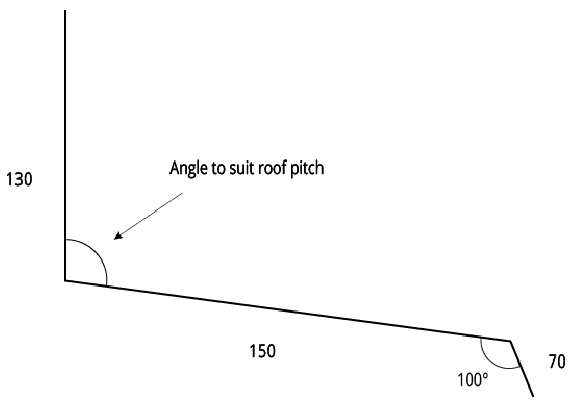

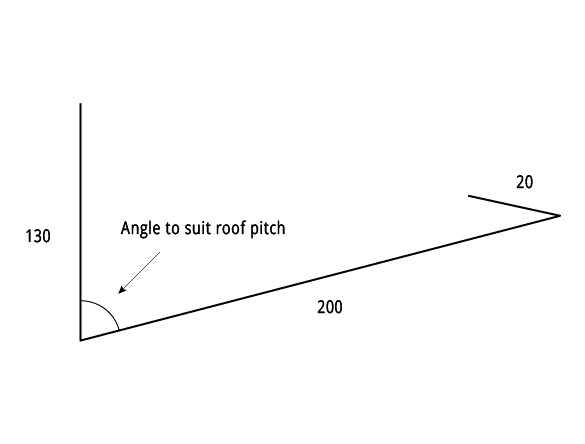

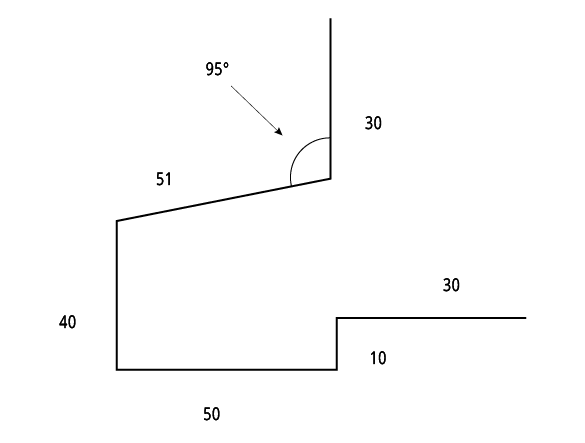

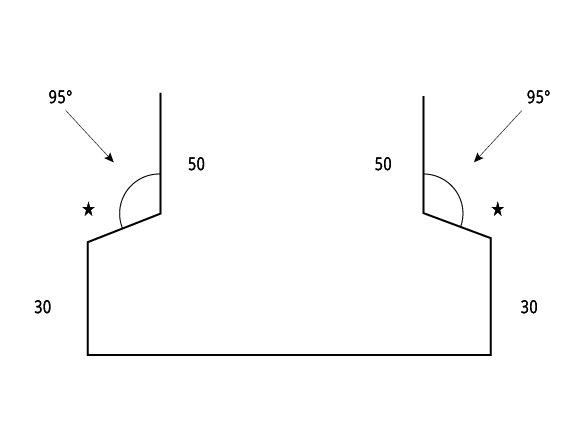

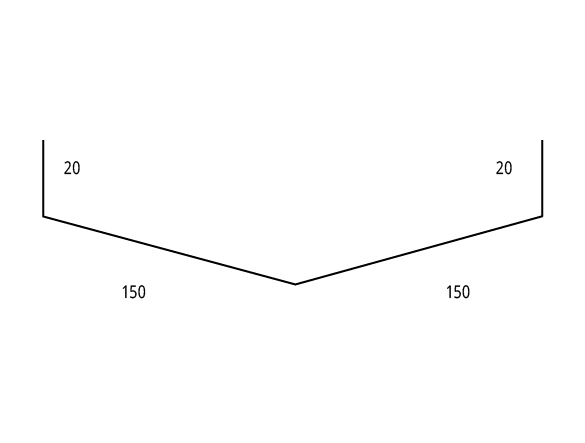

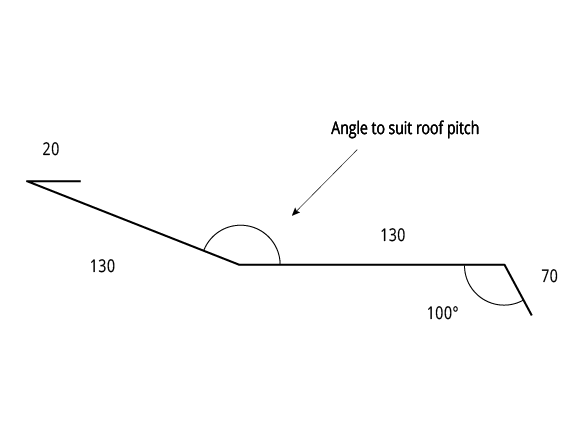

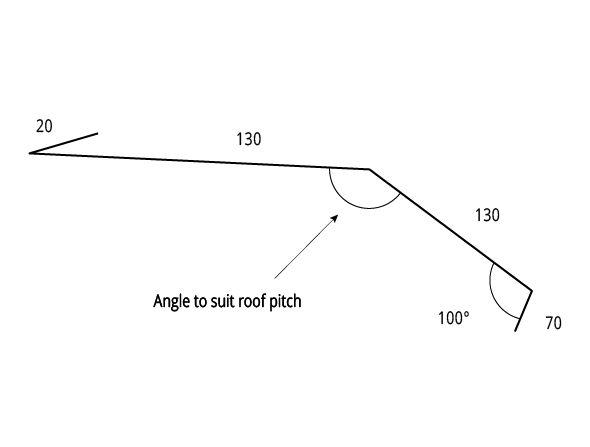

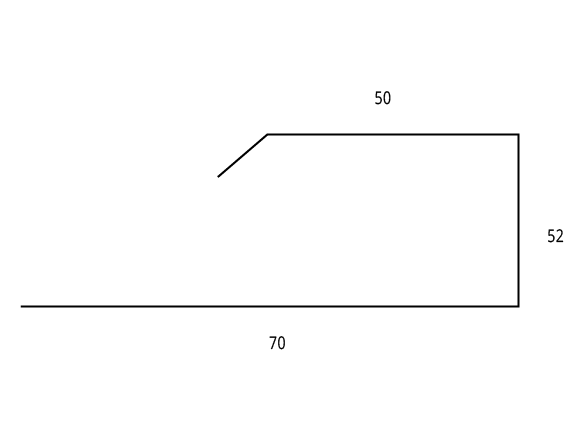

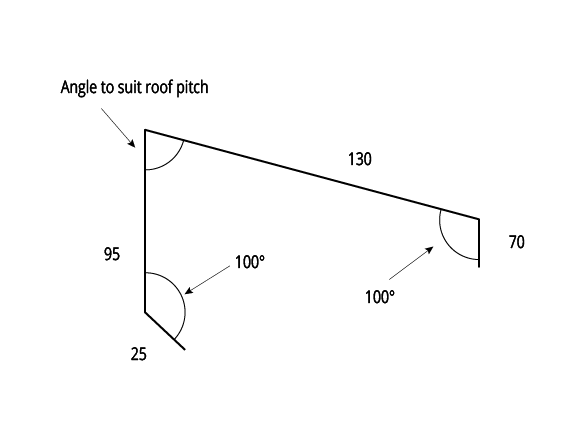

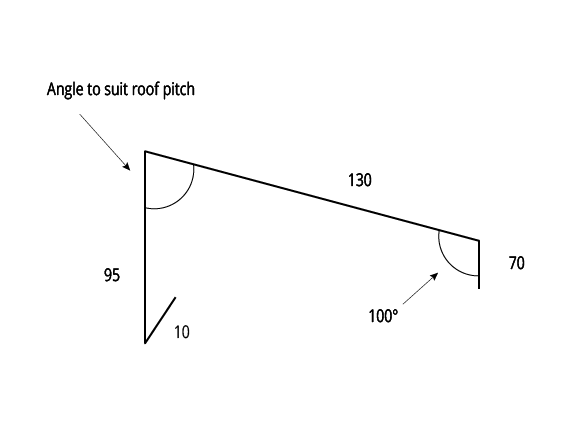

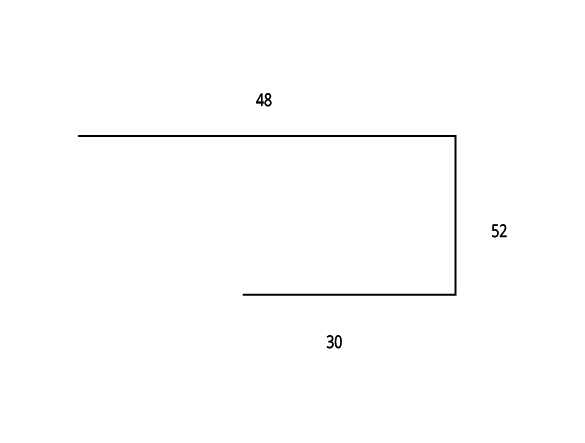

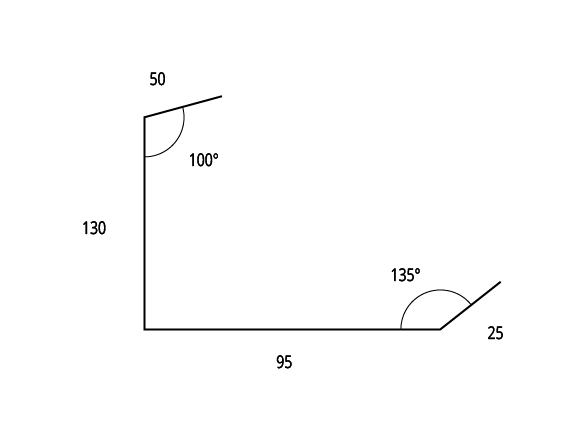

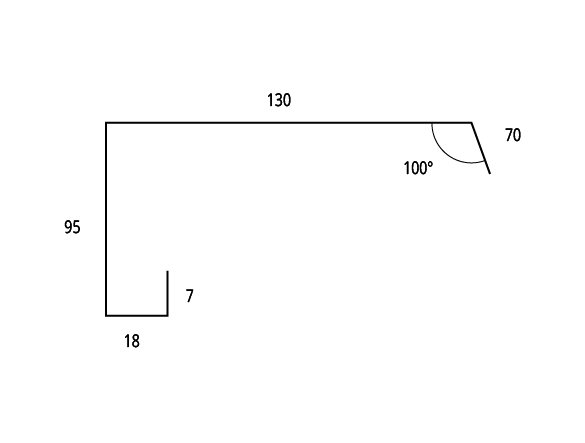

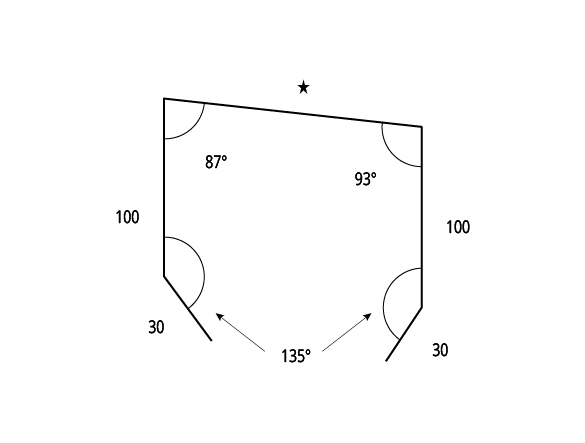

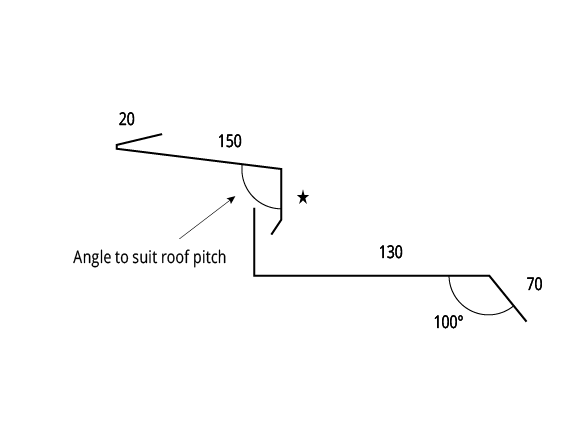

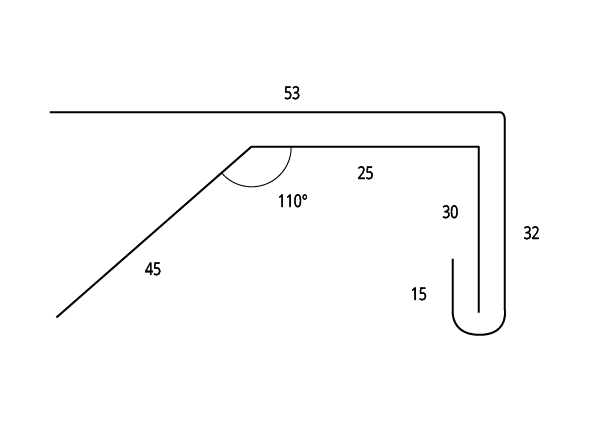

Table HK FD NC 001

Notes:

1. *denotes size to be determined by application. All sizes are in mm and should be used as a guide only.

They should be measured on-site to determine actual size.

2. S.B. denotes ‘ Slight Break’.

3. Also refer to “Typical Roofing Details”.