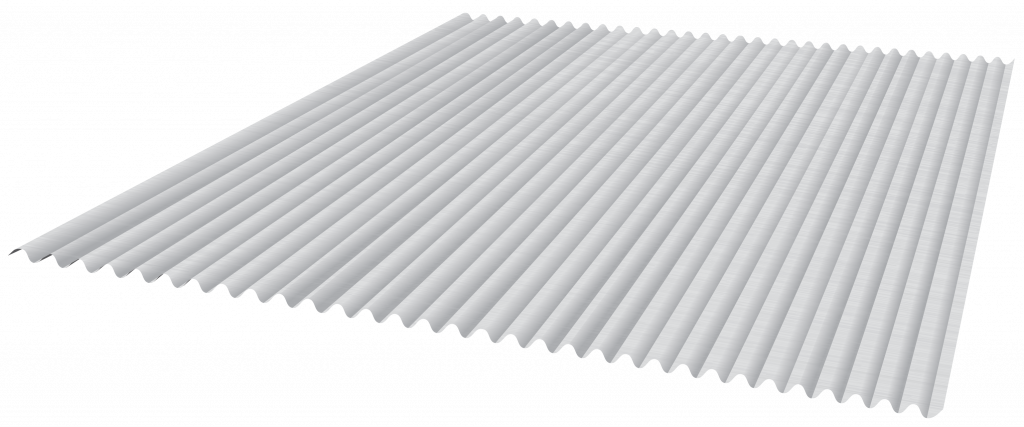

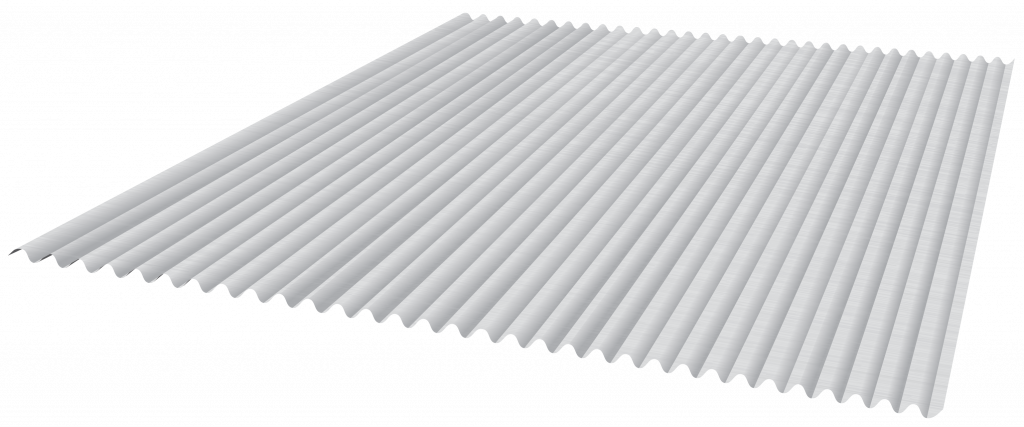

About Mini-Flute

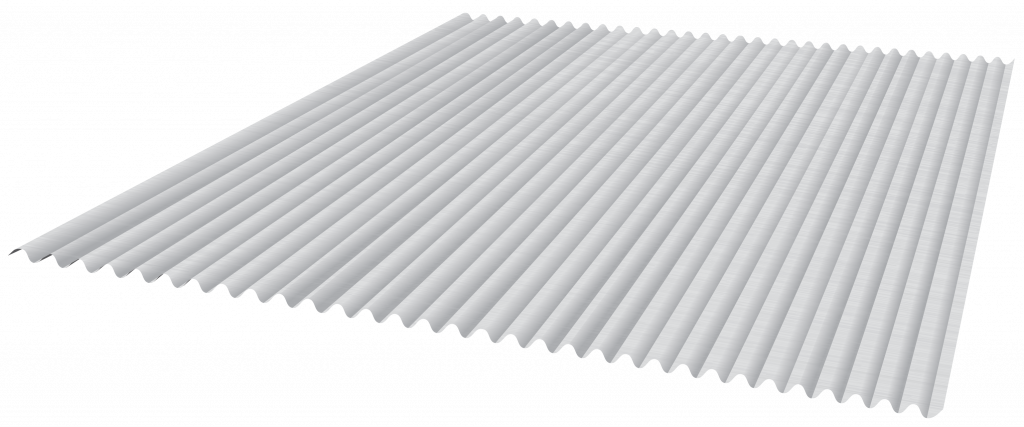

Offering versatile characteristics, Mini-Flute allows for maximum design freedom. The traditional ‘S’ profile maintains a heritage look and in contrast also works as an attractive cladding option on ground breaking architecturally designed buildings. It’s ability to be used vertically, horizontally or diagonally opens a range of stunning design options. While full-length sheets and wide coverage allow for quick installation.

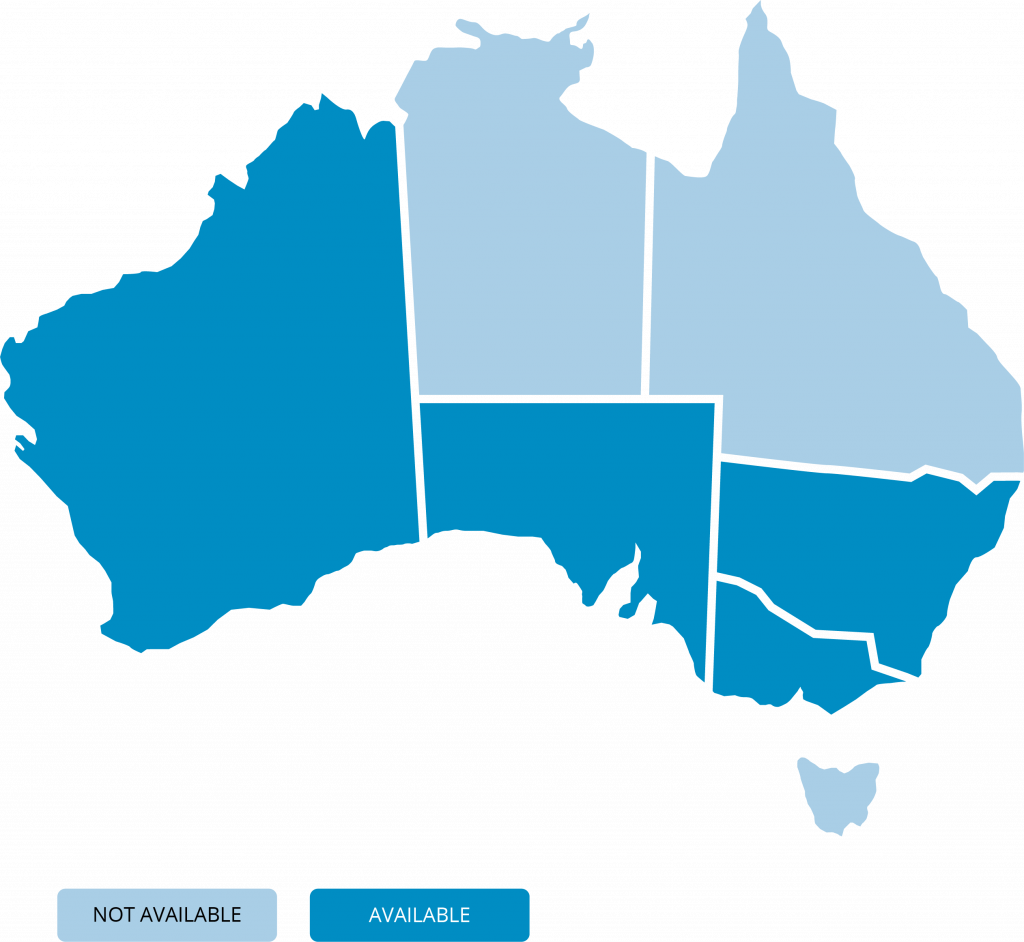

Fielders® Mini-flute is available in COLORBOND® steel, ZINCALUME®, Heritage Galvanised and Stainless Steel, allowing the flexibility to create a modern appearance through to a rustic look. Depending on location, actual product supplied may vary from image shown.

- nsw

- vic

- sa

- wa

You need to select a state...

SK NOTE: I was thinking of putting some placeholder blocks here to indicate there was more content to come (rough example below). But that is being used quite a lot now in apps where content loads automatically - so would be pretty misleading and may lead to a user waiting for something to happen. So still thinking of a better idea here...

Mini-Flute for NSW | VIC | SA

Material Specifications

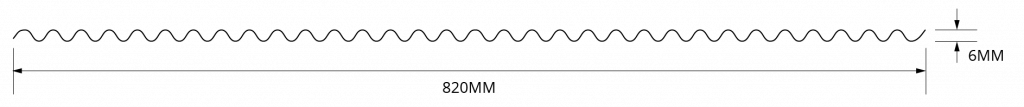

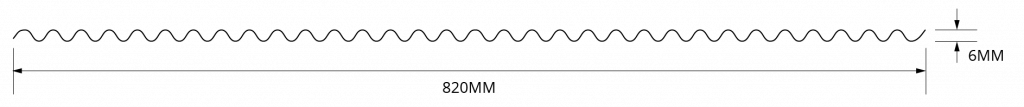

| Property | Notes | ||

| Base Metal Thickness (mm) | 0.42 | BMT | |

| Mass / Unit Area | ZINCALUME® | 3.93 | kg/m2 |

| COLORBOND® | 3.97 | ||

| Minimum Yield Strength | G550 | Base Steel Designation | |

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME ) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

|

| Coverage (mm) | 820 | ||

| Tolerance | Length: +5mm, -5mm, Width: +2mm, -2mm | ||

Notes:

- Mini-Flute is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

Load Span Tables

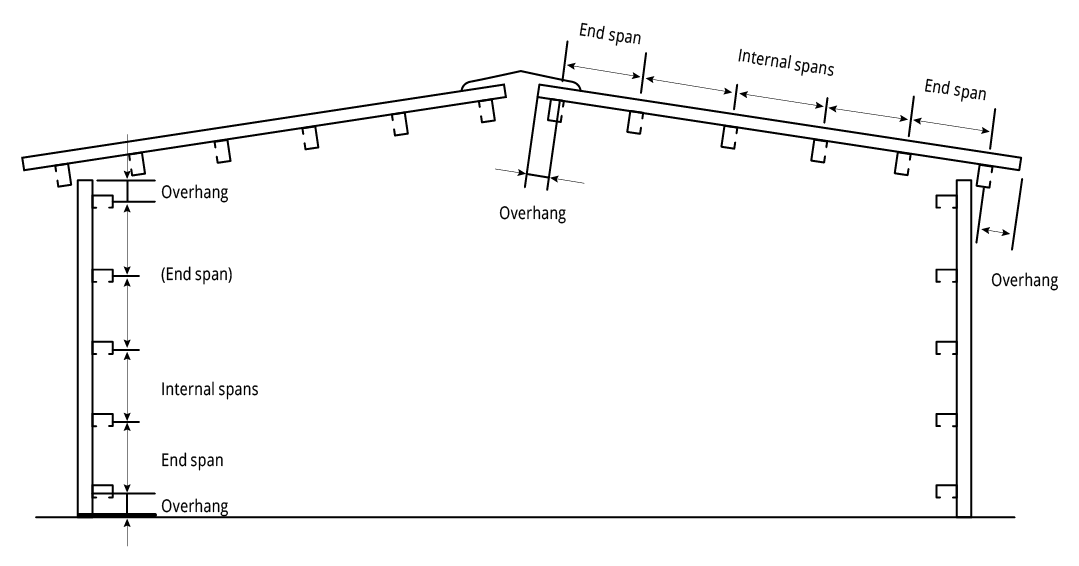

Figure MF NC 001 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Wind Load Capacity: Limit State Design: 0.42mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 450 | 6.20 | 11.70 | 6.50 | 8.80 | 7.00 | 11.70 |

| 600 | 3.99 | 10.15 | 4.69 | 7.30 | 5.23 | 9.25 |

| 900 | 1.17 | 7.65 | 2.17 | 5.10 | 2.67 | 5.85 |

| 1200 | 0.35 | 5.70 | 1.00 | 3.95 | 1.33 | 4.30 |

| 1500 | - | - | 0.34 | 3.15 | 0.46 | 3.50 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | ||

| Single (mm) | End (mm) | Internal (mm) | ||

| B | 0.42 | 1200 | 1500 | 1500 |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor:

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table MF RS NC 001B - Mini-Flute

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

Pierce Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Notes:

All fasteners used externally should be fitted with an EPDM seal (washer). Do not use punches to form fastener holes.

Walling Fixing Details - Valley Fixed

6 fasteners per sheet

Pierce Fixing Table

| Fixing Supports | Valley Fixed (Walling Only) |

| Steel 1.0 to 3.5mm | RippleZips® screws M4.8-16x25 |

| Timber Hardwood & Softwood | RippleZips® screws M4.8-16x25 |

Notes:

- For other steel thicknesses not specified please seek advice from screw manufacturer.

- Values given are: gauge/threads per inch/ lengths (mm).

- Care is required during installation to prevent stripping of thin material.

- Screw specification as above or equivalent fastener.

- RippleZips® screws are not available in Class 4 coating.

Mini-Flute Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving Mini-Flute

Mini-Flute can be curved by hart curving down to a radius of 500mm in either 0.42 BMT, 0.48 BMT or 0.60 BMT to form sheets to traditional heritage shapes and challenging architectural details.

For details regarding spring and smooth curving of Mini-Flute sheets, please see section “Curving of Steel Decks”.

Mini-Flute for NSW | VIC | SA

Material Specifications

| Property | Notes | ||

| Base Metal Thickness (mm) | 0.42 | BMT | |

| Mass / Unit Area | ZINCALUME® | 3.93 | kg/m2 |

| COLORBOND® | 3.97 | ||

| Minimum Yield Strength | G550 | Base Steel Designation | |

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME ) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

|

| Coverage (mm) | 820 | ||

| Tolerance | Length: +5mm, -5mm, Width: +2mm, -2mm | ||

Notes:

- Mini-Flute is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

Load Span Tables

Figure MF NC 001 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Wind Load Capacity: Limit State Design: 0.42mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 450 | 6.20 | 11.70 | 6.50 | 8.80 | 7.00 | 11.70 |

| 600 | 3.99 | 10.15 | 4.69 | 7.30 | 5.23 | 9.25 |

| 900 | 1.17 | 7.65 | 2.17 | 5.10 | 2.67 | 5.85 |

| 1200 | 0.35 | 5.70 | 1.00 | 3.95 | 1.33 | 4.30 |

| 1500 | - | - | 0.34 | 3.15 | 0.46 | 3.50 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | ||

| Single (mm) | End (mm) | Internal (mm) | ||

| B | 0.42 | 1200 | 1500 | 1500 |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor:

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table MF RS NC 001B - Mini-Flute

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

Pierce Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Notes:

All fasteners used externally should be fitted with an EPDM seal (washer). Do not use punches to form fastener holes.

Walling Fixing Details - Valley Fixed

6 fasteners per sheet

Pierce Fixing Table

| Fixing Supports | Valley Fixed (Walling Only) |

| Steel 1.0 to 3.5mm | RippleZips® screws M4.8-16x25 |

| Timber Hardwood & Softwood | RippleZips® screws M4.8-16x25 |

Notes:

- For other steel thicknesses not specified please seek advice from screw manufacturer.

- Values given are: gauge/threads per inch/ lengths (mm).

- Care is required during installation to prevent stripping of thin material.

- Screw specification as above or equivalent fastener.

- RippleZips® screws are not available in Class 4 coating.

Mini-Flute Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving Mini-Flute

Mini-Flute can be curved by hart curving down to a radius of 500mm in either 0.42 BMT, 0.48 BMT or 0.60 BMT to form sheets to traditional heritage shapes and challenging architectural details.

For details regarding spring and smooth curving of Mini-Flute sheets, please see section “Curving of Steel Decks”.

Mini-Flute for NSW | VIC | SA

Material Specifications

| Property | Notes | ||

| Base Metal Thickness (mm) | 0.42 | BMT | |

| Mass / Unit Area | ZINCALUME® | 3.93 | kg/m2 |

| COLORBOND® | 3.97 | ||

| Minimum Yield Strength | G550 | Base Steel Designation | |

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME ) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

|

| Coverage (mm) | 820 | ||

| Tolerance | Length: +5mm, -5mm, Width: +2mm, -2mm | ||

Notes:

- Mini-Flute is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND®; single-sided material. For other painted steel options please contact a Fielders® representative.

Load Span Tables

Figure MF NC 001 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Wind Load Capacity: Limit State Design: 0.42mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 450 | 6.20 | 11.70 | 6.50 | 8.80 | 7.00 | 11.70 |

| 600 | 3.99 | 10.15 | 4.69 | 7.30 | 5.23 | 9.25 |

| 900 | 1.17 | 7.65 | 2.17 | 5.10 | 2.67 | 5.85 |

| 1200 | 0.35 | 5.70 | 1.00 | 3.95 | 1.33 | 4.30 |

| 1500 | - | - | 0.34 | 3.15 | 0.46 | 3.50 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | ||

| Single (mm) | End (mm) | Internal (mm) | ||

| B | 0.42 | 1200 | 1500 | 1500 |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor:

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table MF RS NC 001B - Mini-Flute

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

Pierce Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Notes:

All fasteners used externally should be fitted with an EPDM seal (washer). Do not use punches to form fastener holes.

Walling Fixing Details - Valley Fixed

6 fasteners per sheet

Pierce Fixing Table

| Fixing Supports | Valley Fixed (Walling Only) |

| Steel 1.0 to 3.5mm | RippleZips® screws M4.8-16x25 |

| Timber Hardwood & Softwood | RippleZips® screws M4.8-16x25 |

Notes:

- For other steel thicknesses not specified please seek advice from screw manufacturer.

- Values given are: gauge/threads per inch/ lengths (mm).

- Care is required during installation to prevent stripping of thin material.

- Screw specification as above or equivalent fastener.

- RippleZips® screws are not available in Class 4 coating.

Mini-Flute Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving Mini-Flute

Mini-Flute can be curved by hart curving down to a radius of 500mm in either 0.42 BMT, 0.48 BMT or 0.60 BMT to form sheets to traditional heritage shapes and challenging architectural details.

For details regarding spring and smooth curving of Mini-Flute sheets, please see section “Curving of Steel Decks”.

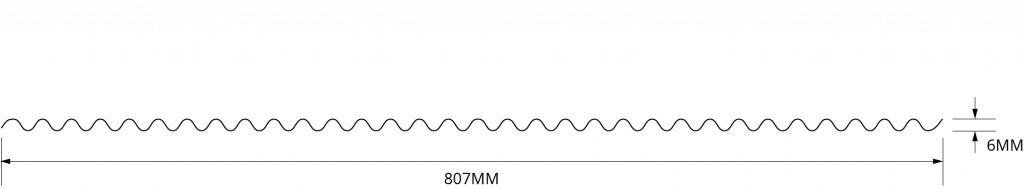

Mini-Flute for WA

Material Specifications

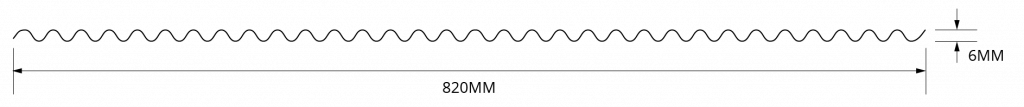

| Property | Notes | ||

| Base Metal Thickness (mm) | 0.60 | BMT | |

| Mass / Unit Area | ZINCALUME® | 5.65 | kg/m2 |

| COLORBOND® | 5.68 | ||

| Minimum Yield Strength | G550 | Base Steel Designation | |

| Coating Class | Z600 (Heritage Galvanised) AM100 (COLORBOND® Steel) AM125 (ZINCALUME ) AM150 (COLORBOND® Ultra Steel) Z450 (Galvanised) | Minimum Coating g/m2 of Zinc - Aluminium |

|

| Coverage (mm) | 807 | ||

| Tolerance | Length: +5mm, -5mm, Width: +2mm, -2mm | ||

Notes:

- Mini-Flute is manufactured from materials in accordance to AS 1397 and AS 2728. It is to be installed in accordance with AS 1562 and HB 39.

- The sectional properties are theoretical values per sheet width. These properties are gross values only.

- *is based on Standard COLORBOND® ; single-sided material. For other painted steel options please contact a Fielders® representative.

Load Span Tables

Figure MF NC 001 End Spans, Internal Spans and Overhangs illustrates the terminology end spans, internal spans, and overhangs and their reference to the supporting substructure. This terminology has been used in the following Maximum Recommended Span and Wind Load Capacity tables.

Wind Load Capacity: Limit State Design: 0.60mm BMT

| Span (mm) | Single Span | End Span | Internal Span | |||

| Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | Serv. (kPa) | Strength (kPa) | |

| 450 | 7.85 | 10.60 | 8.85 | 10.60 | 8.85 | 10.60 |

| 600 | 5.40 | 10.60 | 6.50 | 10.60 | 6.85 | 10.60 |

| 900 | 2.10 | 10.15 | 2.75 | 7.50 | 3.60 | 8.85 |

| 1200 | 0.95 | 7.75 | 1.00 | 5.45 | 1.85 | 6.25 |

| 1500 | 0.58 | 6.45 | 0.60 | 4.40 | 1.05 | 4.60 |

Note:

- Values in the table above have been generated based on testing into steel supports with at thickness of 1.0 mm.

- Values are based on no insulation under the sheeting.

- Serv. denotes serviceability

Maximum Recommended Wall Cladding Span

| Wind Region | Base Metal Thickness (mm) | Terrain Category 3 | ||

| Single (mm) | End (mm) | Internal (mm) | ||

| B | 0.60 | 1500 | 1500 | 1500 |

Importance Level 2

Maximum Roof Height H = 10m

External Pressure Coefficient:

Cpe = -0.65 for walling

Cpe = -0.9 for roofing

Internal Pressure Coefficient:

Cpi = 0.2

Local Pressure Factor:

KL = 2.0 (end & single span)

KL = 1.0 (internal span)

Table MF RS NC 001A - Mini-Flute

Note:

- Maximum walling spans comply with both strength and serviceability wind pressure requirements.

Pierce Fixing

Fasteners must be selected to match the life expectancy of the cladding material. Recommendations from fastener manufacturers should be sought.

Only fasteners complying with AS 3566:2002 and those that are compatible with the roofing material should be used for its fastening.

Notes:

All fasteners used externally should be fitted with an EPDM seal (washer). Do not use punches to form fastener holes.

Walling Fixing Details - Valley Fixed

6 fasteners per sheet

Pierce Fixing Table

| Fixing Supports | Valley Fixed (Walling Only) |

| Steel 1.0 to 3.5mm | RippleZips Screws M4.8-16x25 |

| Timber Hardwood & Softwood | RippleZips Screws M4.8-16x25 |

Notes:

- For other steel thicknesses not specified please seek advice from screw manufacturer.

- Values given are: gauge/threads per inch/lengths(mm).

- Care is required during installation to prevent stripping of thin material.

- Screw specification as above or equivalent fastener.

- RippleZips screws are not available in Class 4 coating.

Mini-Flute Installation Procedure

For installation procedures see section “Typical Pierce Fix Installation Guide”. For general handling instructions refer to section “Maintenance and Care”.

Maximum Sheet Length

See section “Thermal Expansion and Contraction of Steel Sheeting”.

Curving Mini-Flute

Mini-Flute can be curved by hart curving down to a radius of 500mm in either 0.42 BMT, 0.48 BMT or 0.60 BMT to form sheets to traditional heritage shapes and challenging architectural details.

For details regarding spring and smooth curving of Mini-Flute sheets, please see section “Curving of Steel Decks”.